Product Details

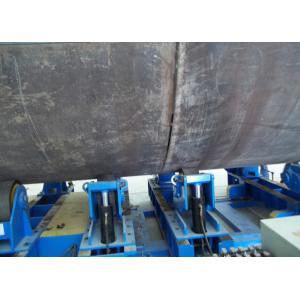

Bolt Welding Turning Rolls Welding Station With Bolt Adjustment

Brief introduction:

- Purpose: For two pipes(1+1) fit up (joint) welding station;

- The station components: HGKZ hydraulic fit up rotator, motorized

travel welding rotator, welding manipulator, welding machine;

Feature of hydraulic fit up rotator:

- Two pieces of distance adjustable rotators, electric system and

hydraulic pump composed the hydraulic fit up rotator.

- Two sets of roller mechanism installed on rotator base.Each roller

mechanism enclosed with PU. Roller distance is regulated by bolt

screw.

- Rotator base is made of welded plate,with feature of high strength

to make sure no deformation in long period using span.Rotator base

& boring is integrated process,so as to guarantee the roller

rotating precision.

- The hydraulic fit up rotator whole structure is processed by temper

destressing.It will be pre-treatment before painting, one layer of

zinc rich primer,two layer of polyurethane finish. Nameplate

indicated loading capacity will be placed on notable position of

the machine body. Main color : green.

- Electric system is composed of electric cabinet & remote control

box.

Detail description of hydraulic fit up rotator:

- The hydraulic fit up rotator is composed of two sets of hydraulic

liftable rotator,hydraulic pump station & control system.

- It is the optimal equipment to increase production

efficiency,insure production quality & decrease labor working

intensity.

- This fit up rotator is mainly used for two pcs cylindrical(or low

angle taper)work piece fit up welding.

- By proper operation, it could regulate the can displacement on

vertical,horizontal or even inclined direction,so as to make the

cans fit up.

- The roller of the equipment is enclosed with high quality PU

wheel,no falling of,long using span. Remote control box is

equipped.

Main Technical Parameters

S/N | Item | HGKZ-80 |

1 | Configuration | 2pc |

2 | Loading capacity | 80t |

3 | Motor power of Pump station | 5.5kw |

4 | Vessel dia. range | Φ600-φ4000mm |

5 | PU wheel dia. | Φ500mm |

6 | PU wheel width | 2x240mm |

7 | Roller material | Imported PU |

8 | Control mode | Wireless remote control |

9 | Voltage | As per user required |

What Ronniewell can do for Ronniewell customers:

1. Give you high quality products.

2. Give you five-star price.

3. Give you suitable recommendation.

4. Give you good after-service.

5. Give you professional technical guide.

6. Warmly welcome you visit our factory.

Workshop:

Exhibition:

Name of the machine:

welding rotator, pipe welding rotator, pipe turning rolls, welding

turning rolls, welding roller, tank turning rolls, pipe turning

rolls, tube turning rolls, fit up rotator, self-aligned welding

rotator, self-aligning welding rotator, self adjustable welding

rotator, self aligned roller stand, wheel frame, roller frame for

wind tower welding, automatic adjustable welding pipe rotator,

conventional welding rotator, bolt adjustable welding rotator, sand

blasting rotator, painting rotator, 1+1 hydraulic fit up rotator,

two in one fit up station

Company Profile

Ronniewell established since 2007 .We have built our expertise

through years of experience. This enables us to produce equipment

suitable for almost the entire spectrum of industrial welding and

cutting needs.

Ronniewell's range of activities includes consultation, design,

manufacture, install and provision of services mainly to Oil & Gas

Installations, Constructors and Heavy Engineering and Steel

Structure Fabricators.

Comprehensive range for sale:

- CNC flame/plasma cutting machine;

- Welding Rotators, Welding Turning Rolls;

- Welding Positioners & Welding Head and tail stocks;

- Welding Column & Boom Manipulators;

- Horizontal turntables;

- Welding Fit Up rotator & Growing Lines;

- Specialist handling welding rotators & welding positioners for

Riser Lines, Pipe Shops, Pile Racks, Double Jointing, and Wind

tower Production solutions.

- H-beam production lines;

- Edge milling machine.

Our vision is based on a long term strategy. This means that we are

increasing our design and production capacity and we are

strengthening our sales and after sales team to be able to serve

you in the best possible way.