Specifications

1. Eliminate the need for expensive hand masking

2. Reduce costly defects and rejects

3. Improve throughput by quality and volume

Description:

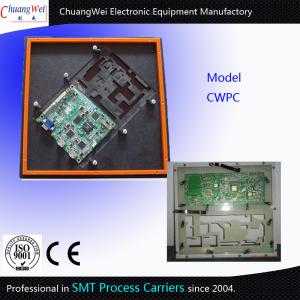

Chuangwei Engineering specializes in selective wave solder pallets.

Designed by engineers with extensive wave solder experience, our

pallets enable customers to automate the soldering of through-hole

components on complex electronic assemblies.

The pallets only expose areas of the assembly that require

soldering. All other areas are protected, eliminating component

damage and expensive, low quality process steps. Made of ESD-safe

composite materials, these pallets are designed and manufactured to

optimize both the solder ability of your circuit boards and your

entire process flow.

Cost Effective

1). Eliminate hand soldering processes

2) Eliminate high-defect, surface mount glue operations

3) Eliminate temporary solder masking operations

4) Reduce assembly cycle time

5) Use Fiberglass or Aluminum Stiffeners to avoid deforming.

Improves Quality

1) Improve component alignment and soldering

2) Improved solder fill and quality

3) Eliminates flooding problems

Increases your flexibility

1) Eliminates board size / panelization issues

2) Standardize on conveyor width

3) Effectively process complex, double-sided surface mount

assemblies

Easy to Use

1) Designed by engineers with extensive wave solder experience

2) Optimized for easy profiling

3) Supports rapid set-up using our ergonomically designed fasteners

4) Optimized for best soldering

5) Wave solder automation to solder through-hole components on

complex electronic assemblies.

And we can design pallet for customers, if possible, please kindly

advise me below information to design pallets as your requested..

a. CAD machined drawing or 3D drawings (such as STP, STEP, IGS,

IGES etc.) of wave solder pallets

b. Gerber file of PCB board(Bare)+Sample PCBA Board(Loaded)

Benefits

1. Wave Solder Pallets provide strong, stable support for the PCB

throughout the wave solder process

2. Wave Solder Pallets permit wave solder processing of

through-hole components while masking solder-side SMT components

and critical board features from molten solder

3. Wave Solder Pallets provide thermal protection for printed

circuit board areas that are heat sensitive

4. Wave Solder Pallets allow processing of odd-shaped PCB's through

conveyor system

5. Wave Solder Pallets prevent topside component movement

throughout wave solder

6. Wave Solder Pallets align and position topside components

throughout wave solder

7. Wave Solder Pallets increase assembly production by eliminating

hand gluing and masking operations

8. Wave Solder Pallets ensure higher quality, repeatable process

results

9. Wave Solder Pallets reduce bridging and skipping solder defects

10. Wave Solder Pallets provide safe, easy, ergonomic handling of

PCB

Specification:

| Model | DurostoneCHP760 | DurostoneCAS761 | DurostoneCAG762 |

| Grade | Standard | Anti-Static | Anti-static(Optical) |

| Colour | Blue | Black | Grey |

| Density(g/mm3) | 1.85 | 1.85 | 1.85 |

| Standard OperationTemperature | 260 | 260 | 260 |

| Maximum Operation Temperature(C) | 350 | 350 | 350 |

| Sheet Size(mm) | 2440×1220 | 2440×1220 | 2440×1220 |

| Tickness/weight(mm/kg) | 3/17, 4/22 | 5/28, 6/33, 8/44 | 10/55, 12/66 |

CE approval

If you're in need of PCB pallet,please contact us:

Email: s5@smtfly.com

Wechat/Whatsapp: +86 136 8490 4990