Add to Cart

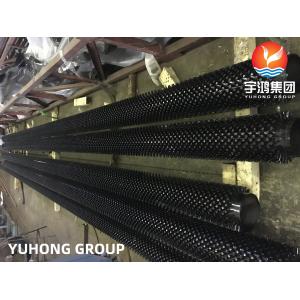

ASTM A335 P9 P11 Alloy Steel Seamless Tube HFW Stud Finned Tube For Heat ExchangerHRSG Boiler Fired heater Evaporator

Yuhong Group has been operating stainless steel/duplex/nickel seamless pipes for more than 10 years, with annual sales of more than 80,000 tons of stainless steel/duplex/nickel seamless pipes. Our clients have covered more than 45 countries. Our stainless steel seamless pipes are widely used in mining, energy, petrochemical, chemical, food mills, paper mills, gas and fluid industries and more. ANSI B16.10: B16.19 SCH 5S, SCH 10S, SCH 20, SCH 30, SCH 40S, SCH 60, SCH80S, XS, SCH 100, SCH 120, SCH160, XXS

HFW solid finned tube Abbreviation for high frequency welded helical helical solid finned tube

Spiral finned tubes provide designers with high thermal efficiency and a compact design solution for a variety of heat exchangers using clean flue gas. There are two types of spiral finned tubes: solid type and serrated type.

Helical solid finned tubes are manufactured by helically wrapping a continuous strip of fins around the tube. High frequency resistance welding typically uses a frequency of 400 kHz. The fins are wrapped around the tube and welded continuously. The fin tape is helically wound on the tube and continuously welded to the base tube along the root of the helix by a high frequency electrical process. The finned band is held under tension and laterally restrained as it is formed around the tube, ensuring that the band is in strong contact with the surface of the base tube. Using the gas metal arc welding process, the continuous welding is performed where the fin strip first begins to bend around the diameter of the tube.

For a given tube or pipe size, the required heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and/or number of fins per meter of length.

HFW Solid Finned Tube

This welded steel finned tube configuration can be used in any practical heat exchanger application, especially for high temperature and high pressure applications. Important features of this configuration are the efficient and effective bonding of the fin to the tube, and the ability to withstand high temperatures on the fin side under all temperature and pressure conditions.

A continuous helical fin is attached to the base tube by high frequency electric resistance welding in order to give an efficient and thermally reliable bond.

Technical Details/Base Tube Details

Pipe Diameter: Min. OD 20mm to Max. OD 219mm.

Tube Thickness: Min. 2mm to 16mm

Tube Materials: Carbon Steel, Stainless Steel, Alloy Steel, Weathering Steel, Duplex Steel, Super Duplex Steel, Inconel, High Chromium High Nickel and Chromium Alloys, CK 20 material and some others.

Fin Details

Fin Thickness: Min. 0.8 mm to max. 4 mm

Fin Height: Min. 0.25" (6.35mm) to Max. 1.5" (38mm)

Fin Density: Min. 43 fins per meter to max. 287 fins per meter

Materials: Carbon Steel, Stainless Steel, Alloy Steel, Weathering Steel, Duplex Steel and Incolloy.

For a rapid quotation, plz send with following requirement:

Number of pieces,

base tube: Diameter, thickness, length and material specification.

Fins: material specification, type (solid or serrated), height, thickness, spacing, finned length and unfinned sections. Weld prep details if required.

Delivery period required.

Keywords: Fin tubes, Finned tube, Finned Pipe Helical Finned Tubes, Solid fin tubes, Serrated finned tube, Helical Serrated Finned Tubes, Tubos Aletados

| * These are the most common fin/tube patterns. We have more than 20 different plate fin and tube combinations. Contact me for more information and options. | ||

| Helical Fin Surface (Tube OD – Available Helical Fin Height on the Tube) | ||

| 5/8″ – 3/8″, 1/2″ and 7/16″ | 1″ – 3/8″, 1/2″ , 7/16″ and 5/8″ | 1 1/4″ – 3/8″, 1/2″ , 7/16″ and 5/8″ |

| 15.875mm – 9.525mm, 12.7mm and 11.113mm | 25.4mm – 9.525mm, 12.7mm, 11.113mm and 15.875mm | 31.75mm – 9.525mm, 12.7mm, 11.113mm, and 15.875mm |

| ||