Add to Cart

Extruded High Fin Tubes Machine With Raw Materials CS / SS / AS / Copper / Alu / Titanium Tubes For Cooling Heating

1.Product Details:

2.Payment & Shipping Terms:

3.Detailed Product Description

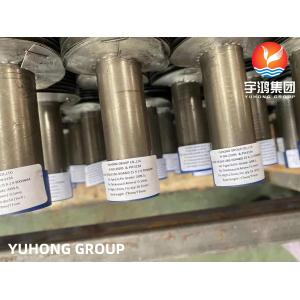

Extruded High Fins Tubes Machine with raw materials CS / SS / AS / Copper / Alu / Titanium Tubes

PS: This is the finning machine that can produce extruded high fin tubes and low fin tubes.

4.Details

5.General Description of Extruded finning machine.

1. Extrusion machine mode No: Reliance-1118(Our internal design No.)

2. Extrusion equipment power output: 380V/50HZ (Chinese Standard).

3. The motors of export extrusion finning machine are supplied upon clients’ requests.

6.One complete set of Extruded Finning Machine consisting following:

1. Finning head

2. Cooling systems for finning head

3. Finning input racks

4. Finning output racks

5. Extrusion tooling disks(knives) in groups

6. Technical know-how(Operation Manual in English)

7.Service After Sales

1. Technical support

2. Operation training at your site or in Reliance's Plant or both

3. Information on maximun production criteria

4. Reference charts

5. Specifications for tube and fin stock

8.FAQ:

| Q | A | |

| 01 | How many days you need to install the equipment? | 30 days. |

| 02 | How many staff abroad you sent to install the equipment? | 3 persons. |

| 03 | Can I delivery the goods from other supplier to your factory? Then load together? | Yes. |

| 04 | Can the equipment be installed under hot weather? | Yes. |

| 05 | Can Your products be installed under the cold weather? | Yes. |

| 06 | Can I only buy some spare parts from you? | Yes. |

| 07 | Will you participate in the exhibition? | Will do . |

| 08 | How long it takes you to provide the designing options for us? | 1-2 working days . |

| 09 | What is your products standardization? | National standard . |

| 10 | How do you pack the equipment? | Wooden box . |

| 11 | Can you can design the equipment according to our size? | Yes. |

| 12 | How many years have your company made this kind of equipment? | 13 years . |

| 13 | Which certificate do you have for your equipment? | ISO |

| 14 | Do you have any real project pictures of the equipment? | Yes. |

| 15 | How far is your factory from the airport? | 50 minutes . |

| 16 | How long it will take from guangzhou to your factory? | 2 hours by plane, 9-10 hours by high-speed rail. |

| 17 | Do you provide sample? Free or charge? | Samples can be provided, charges are required. |

| 18 | What is your term of payment? | 30% prepaid, paid in full before shipment. |

| 19 | What is your MOQ? | 100 pcs . |

| 20 | Are you a trading company or a manufacturer? | Manufacturer. |

| 21 | How long is your delivery time? | 40 days . |

| 22 | How many production lines in your factory? | 7 high-frequency resistance welding spiral fin tube production lines, 3 tube bending machines, 18 rolling extruders, 12 aluminum fin winding and inlaying machines. |