Add to Cart

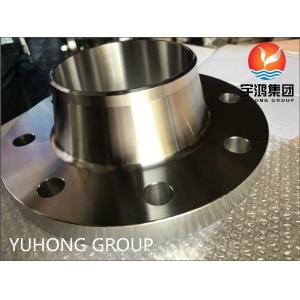

The material composition of ASTM A182 F60 flanges contains 3-3.5% molybdenum. This level has different pressure levels, ranging from CLASS 150 to 2500 LBS. YUHONG GROUP is the leading supplier and manufacturer of these f60 duplex stainless steel flanges in various sizes and shapes. Standards include ASME B16.47, B16.5 and B16.48, with diameters ranging from ½ inch to 48 inches. The pressure-bearing capacity of the flange is expressed in the JIS system from 5K to 63K, and in the EN and UNI system from 6Bar to 40Bar.

These can be forged, processed and heat treated. ASTM a182 F60 UNS

S32205 BLRF flange is a blind raised face flange. Blind flanges are

used to close the connection. The raised face supports additional

connection space or accessory space. Flanges can be divided into

flat type, raised surface type and ring type connection flange

according to the surface type. The astm a182 gr f60 SORF flange is

a sliding on the raised face flange, and the pipe can be slid to

the correct connection point.

The melting point of the flange material is 1420 degrees Celsius.

This allows the flange to operate at high temperatures. There is a

welding neck on the A182 F60 welding neck flange, which can hold

the pipe to the greatest extent during the welding process. The

material has high fatigue strength and is easy to weld. Gaskets are

used to fasten flanges and pipes together during welding. We can

provide f60 duplex stainless steel sliding flanges and other

products. Please feel free to contact us for more information and

prices.

Manufacturing and Heat Treatment

ASTM A182 F60 flanges shall be manufactured by hot forging. The

steel shall be forged as close as possible to the specified shape

and dimensions of the flange. The optimum forging temperature

should be controlled between 1100°C [2000°F] and 1150°C [2100°F].

If the forging temperature is higher than 1150°C [2100°F], the

dimensional stability of the workpiece may be affected and the

tendency to form scale increases above this temperature. If the

forging temperature is much lower than 1100°C [2000°F], significant

amounts of detrimental intermetallic phases may form, leading to

cracking in the deformed area. After hot forging, ASTM A182 F60

flanges shall be solution treated at a temperature not lower than

1870°F [1020°C]. Flanges should be soaked at this temperature long

enough to dissolve any intermetallic precipitates. After complete

solution annealing, rapid quenching should be carried out.

Pitting resistance equivalent number

ASTM A182 F60 flanges have excellent resistance to pitting

corrosion, especially in chloride containing solutions. The main

elements that contribute to resistance to pitting corrosion are

chromium (Cr), molybdenum (Mo) and nitrogen (N). Based on these

elements, an index for comparing resistance to localized pitting

corrosion was developed. This indicator is called Pitting

Resistance Equivalent Number (PREN). PREN of ASTM A182 Gr. F60 is

defined in weight percent using the following equation: PREN = Cr +

3.3Mo + 16N. The higher the PREN, the better the ASTM A182 F60

flange will perform in chloride environments.

check

Dimensional inspection, visual inspection, tensile test, thermal

analysis, PMI, harmful phase inspection according to ASTM A923,

pitting and crevice corrosion resistance test according to ASTM

G48, ultrasonic testing, dye penetrant inspection.

Full Specification for Weld Neck Flange:

1. Standards:

(1) American Standard

ASME/ANSI B 16.5

(2) German Standard

DIN2641, DIN2642

(3) British Standard

BS 1560, BS 4504

(4) Australian & Japanese Standard

JIS B2220 / KS B1503, AS2129,

2. Material:

F60 (F50, F51, F52, F53, F54, F55, F57, F59, F60, F61, F69, etc.)

| Ferritic-Austenitic Stainless Steels | ||||||||||||

| Composition, % | ||||||||||||

Grade/ Identification | UNS Designation | Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum | Columbium | Titanium | Other Elements |

| F 50 | S31200 | 0.030 | 2.00 | 0.045 | 0.030 | 1.00 | 5.5-6.5 | 24.0-26.0 | 1.20-2.00 | - | - | N 0.14-0.20 |

| F 51 | S31803 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5–6.5 | 21.0–23.0 | 2.5–3.5 | - | - | N 0.08–0.20 |

| F 69 | S32101 | 0.040 | 4.00–6.00 | 0.040 | 0.030 | 1.00 | 1.35–1.70 | 21.0–22.0 | 0.10–0.80 | - | - | N 0.20–0.25 Cu 0.10–0.80 |

| F 52 | S32950 | 0.030 | 2.00 | 0.035 | 0.010 | 0.60 | 3.5–5.2 | 26.0–29.0 | 1.00–2.50 | - | - | N 0.15–0.35 |

| F 53 | S32750 | 0.030 | 1.20 | 0.035 | 0.020 | 0.80 | 6.0-8.0 | 24.0--26.0 | 3.0-5.0 | - | - | N 0.024-0.32 Cu 0.50 |

| F 54 | S39274 | 0.030 | 1.00 | 0.030 | 0.020 | 0.80 | 6.0-8,0 | 24.0-26.0 | 2.5-3.5 | - | - | N 0.24-0.32 Cu 0.20-0.80 |

| F55 | S32760 | 0.030 | 1.00 | 0.030 | 0.010 | 1.00 | 6.0-8.0 | 24.0-26.0 | 3.0-4.0 | - | - | N 0.20-0.30 Cu 0.50-1.00 |

| F 57 | S39277 | 0.025 | 0.80 | 0.025 | 0.002 | 0.80 | 6.5-8.0 | 24.0-26.0 | 3.0-4.0 | - | - | Cu1.20-2.00 NW 0.80-1.20 |

| F 59 | S32520 | 0.030 | 1.50 | 0.035 | 0.020 | 0.80 | 5.5-8.0 | 24.0-26.0 | 3.0-5.0 | - | - | N 020-0.35 Cu 0.50-3.00 |

| F 60 | S32205 | 0.030 | 2.00 | 0.030 | 0.020 | 1.00 | 4.5-6.5 | 22.0-23.0 | 3.0-3.5 | - | - | N 0.14-0.20 |

| F 61 | S32550 | 0.040 | 1.50 | 0.040 | 0.030 | 1.00 | 4.5-6.5 | 24.0-27.0 | 2.9-3.9 | - | - | Cu 1.50-2.50 N 0.10-0.25 |

3. Pressure Ratings:

PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN80, PN100, PN250, PN320, PN400

150LB, 300LB, 400LB, 600LB, 900LB, 1500LB, 2500LB;

4. Size Range:

1/2" ~ 24" (DN15 ~ DN600)

Dimensions and weights of Class 150 Flange

SIZE | FLANGE | BARREL | BOLTING | Raised Face Dia. R | LENGTH L | WEIGHT | |||||

Nom | Unit | Bore B | OD O | Thk T | OD D | No. OF Holes | Hole Size | Bolt Circle C | POUND KILO | ||

1/2 | mm inches | 12,7 0,50 | 88,9 3,50 | 11,2 0,44 | 31,8 1,25 | 4 | 15,7 0,62 | 60,5 2,38 | 34,9 1,38 | 228,6 9,00 | 3 1,36 |

3/4 | mm inches | 19,1 0,75 | 98,6 3,88 | 12,7 0,50 | 41,1 1,62 | 4 | 15,7 0,62 | 69,9 2,75 | 42,9 1,69 | 228,6 9,00 | 5 2,27 |

1 | mm inches | 25,4 1,00 | 108,0 4,25 | 14,2 0,56 | 50,8 2,00 | 4 | 15,7 0,62 | 79,2 3,12 | 50,8 2,00 | 228,6 9,00 | 7 3,17 |

1 1/4 | mm inches | 31,8 1,25 | 117,3 4,62 | 15,7 0,62 | 60,5 2,38 | 4 | 15,7 0,62 | 88,9 3,50 | 63,5 2,50 | 228,6 9,00 | 10 4,54 |

1 1/2 | mm inches | 38,1 1,50 | 127,0 5,00 | 15,5 0,69 | 66,5 2,62 | 4 | 15,7 0,62 | 98,6 3,88 | 73,0 2,88 | 228,6 9,00 | 12 5,44 |

2 | mm inches | 50,8 2,00 | 152,4 6,00 | 19,1 0,75 | 82,6 3,25 | 4 | 19,1 0,75 | 120,7 4,75 | 92,1 3,63 | 228,6 9,00 | 15 6,81 |

2 1/2 | mm inches | 63,5 2,50 | 177,8 7,00 | 22,4 0,88 | 95,3 3,75 | 4 | 19,1 0,75 | 139,7 5,50 | 104,8 4,13 | 228,6 9,00 | 22 9,98 |

3 | mm inches | 76,2 3,00 | 190,5 7,50 | 23,9 0,94 | 108,0 4,25 | 4 | 19,1 0,75 | 152,4 6,00 | 127,0 5,00 | 228,6 9,00 | 25 11,35 |

3 1/2 | mm inches | 88,9 3,50 | 215,9 8,50 | 23,9 0,94 | 124,0 4,88 | 8 | 19,1 0,75 | 177,8 7,00 | 139,7 5,50 | 228,6 9,00 | 32 14,52 |

4 | mm inches | 101,6 4,00 | 228,6 9,00 | 23,9 0,94 | 139,7 5,50 | 8 | 19,1 0,75 | 190,5 7,50 | 157,2 6,19 | 304,8 12,00 | 47 21,33 |

5 | mm inches | 127,0 5,00 | 254,0 10,00 | 23,9 0,94 | 165,1 6,50 | 8 | 22,4 0,88 | 215,9 8,50 | 185,7 7,31 | 304,8 12,00 | 57 25,87 |

6 | mm inches | 152,4 6,00 | 279,4 11,00 | 25,4 1,00 | 196,9 7,75 | 8 | 22,4 0,88 | 241,3 9,50 | 215,9 8,50 | 304,8 12,00 | 75 34,05 |

8 | mm inches | 203,2 8,00 | 342,9 13,50 | 29,4 1,12 | 247,7 9,75 | 8 | 22,4 0,88 | 298,5 11,75 | 269,9 10,63 | 304,8 12,00 | 102 46,30 |

10 | mm inches | 254,0 10,00 | 406,4 16,00 | 30,2 1,19 | 304,8 12,00 | 12 | 25,4 1,00 | 362,0 14,25 | 323,9 12,75 | 304,8 12,00 | 143 64,92 |

12 | mm inches | 304,8 12,00 | 482,6 19,00 | 31,8 1,25 | 365,3 14,38 | 12 | 25,4 1,00 | 431,8 17,00 | 381,0 15,00 | 304,8 12,00 | 205 93,07 |

14 | mm inches | 355,6 14,00 | 133,4 31,00 | 35,1 1,38 | 406,4 16,00 | 12 | 28,4 1,12 | 476,3 18,75 | 412,8 16,25 | 304,8 12,00 | 211 95,79 |

16 | mm inches | 406,4 16,00 | 596,9 23,50 | 36,6 1,44 | 457,2 18,00 | 16 | 28,4 1,12 | 539,8 21,25 | 469,9 18,50 | 304,8 12,00 | 246 111,68 |

18 | mm inches | 457,2 18,00 | 635,0 25,00 | 3,96 1,56 | 508,0 20,00 | 16 | 31,8 1,25 | 577,9 22,75 | 533,4 21,00 | 304,8 12,00 | 270 122,.58 |

20 | mm inches | 508,0 20,00 | 698,5 25,50 | 42,9 1,69 | 558,8 22,00 | 20 | 31,8 1,25 | 635,0 25,00 | 584,2 23,00 | 304,8 12,00 | 311 141,19 |

24 | mm inches | 609,6 24,00 | 812,8 32,00 | 4,78 1,88 | 666,8 26,25 | 20 | 35,1 1,38 | 749,3 29,50 | 692,2 27,25 | 304,8 12,00 | 423 192,04 |

The end face type of flange A182 F60 can also be different, such as flat, raised and ring joint flanges. Flat flanges have flat surfaces, which allows them to be used in narrow spaces, where raised flanges have many surfaces for bolting and welding connections. The ring flange is divided into two halves, which are welded to different pipe ends, and they are combined by welding to obtain the maximum seal.

Flanges are part of the piping system and are used inside or

outside the pipeline. Many types of flanged pipes are commonly used

in piping systems. Flanges are like bridges, connecting pipes or

fittings, making the pipe a complete system. Flange is an

indispensable part of connecting pipes.

Pipe fittings are parts used to install or repair pipelines or

pipeline systems that transport liquid, gas, and solid materials.

This work includes selecting and preparing pipes or pipes,

connecting them together in various ways, and locating and fixing

vulnerabilities.