YUHONG HOLDING GROUP is one of the largest Procurement, Engineering & Contracting Group

companies in China. Our group branch company and factory have been already approved by

: ABS, LR, DNV, GL, BV, CCS, KR, PED 97/23/EC, AD2000-WO,

GOST9941-81, CCS, TS, CNNC, ISO9001-2015, ISO 14001, ISO 18001, API

5L , API 5CT , API 6D, And our branch company Zhejiang Yuhongwell Steel Co.Ltd has

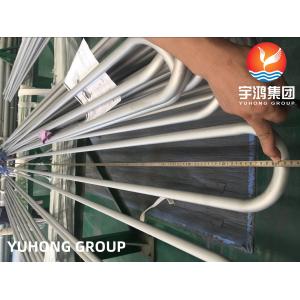

expanded its field of activities and entered in trade and supply of

tubular & flat products in Duxplex and Super Duplex, Stainless Steel, Nickel Base alloy Steel ,Cr-Mo alloy steel , Copper Nickel alloy steel,Carbon Steel for our reputed clients worldwide. These products are widely used

in various important sectors like Mining, Energy, Boiler & Heat

Exchanger, Petrochemical, Chemical Industry, Food plant, Paper

plant, Gas and Fluid Industry etc.

YUHONG HOLDING GROUP has gained rich experience in Pipes, Fittings,

Flanges, Valves, Structural steel, Coils and Plates in past eight

years. In a short span of time, YUHONG brand has marked its global

presence in more than 40 countries, like, Korea, USA, Canada,

Mexico, Colombia, Bolivia, Chile, Argentina, Brazil, Ecuador,

Austria, New Zealand, Singapore, Malasyia, Indonesia, Thailand,

Vietnam, Ukraine, Turkey,Sauid Arabia, Qatar, U.A.E,Israel,India,

UK, France, Italy, Gernmany, Poland, Spain,... We have successfully

implemented the orders of Cross Country Pipelines for our valuable

customers. In addition, we have also developed a huge network of

contacts and strategic alliances with most important manufacturers

an stockists around the world.