Add to Cart

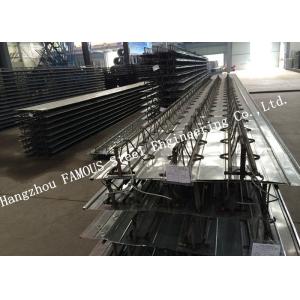

Steel bar truss girder is composite of corrugated sheet and steel

bar truss which replace wooden template to bear all the

construction loads in the construction phase and participate in

bearing structure load in the service stage. Composite deck is

floor deck which replace all or part of the force steel bar and

work together with concrete in the service stage, while steel sheet

of steel truss deck does not participate in bearing structure load,

it's non-composite deck.

The steel bar truss deck is a new metal deck design and it is

widely applied for the mezzanine construction of commercial and

civilian buildings, such as factories, hospitals, gymnasiums,

schools, bridge projects and residential buildings. The steel bar

truss deck is composed of two parts, the steel bar truss and the

galvanized steel sheet.

Specifications:

| Width | 576mm /600mm according to project needs/design |

| Overlap Width | 566mm /590mm etc |

| Maximum length | 11.8m or custom requirement |

| Height | 70-270mm etc |

| Top and bottom bar diameter | 6-12mm etc |

| Cross bar diameter | 4-8mm etc |

| Decking thickness | Galvanized steel sheet 0.5mm etc |

ADVANTAGES

1. Steel bars are evenly arranged and the bearing mode is

reasonable, which greatly reduces the engineering quantity of

temporary support.

2. The double edgefold design can effectively ensure the quality of

the engineering.

3. It can shorten the time by reducing 60% to 70% work load of

binding steel bars.

4. It has the same mechanical properties and fire resistance as

that of traditional cast-in-place floors. Because the bottom mould

does not join in the load-baring, it is unnecessary to consider

fire proof and anticorrosion.

While FASEC Rebar-truss triangle welded metal decking system adapts rapid construction requirements of the main steel structure and provide fast work procedures. It can save a lot of construction time compared to traditional floor decking system. It can also improve the rigidity of the floor and save the amount of steel and concrete, so as to reduce the project budget.

The Surface embossed increase the bonding of floor deck and concrete, make the floor deck system has high-strength bearing capacity. It is totally fire-proof and can span long without middle propping.

So from cost saving and time saving view, the FASEC rebar-truss triangle welded metal decking system is better choice. However, in much of ready design, the deck is already designed and in avoiding of redesign, recalculation and re-submit/approval, we can also offer various customized steel floor deck profiles to cater for various contractors’ need, meanwhile we will offer various technical support in the aspects of load span and stress analysis etc.

Following are some typical detail:

Warmly welcome various clients from International market to enquiry and visit us!