Add to Cart

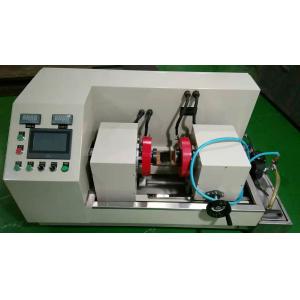

HMP-500NX High Precision Magnetic Particle Flaw Detector For Training Purposes

1. Equipment component description

1.1. Electric control cabinet (1)

Independent electric control cabinet, all electric executive components are installed in this control cabinet, and the electric control cabinet is equipped with an air filtering and circulating heat dissipation device. Welded with high-quality steel;

A 220V 50HZ spray pump with a waterproof cover and a power output of the black light lamp are installed at the rear;

Circuit breakers, contactors, control components, transformers, rectifiers, triggers, energy, etc. are all installed in this cabinet;

1.2. Control panel (2)

The front of the panel is designed with a touch screen for setting and display, with AC digital ammeter and emergency stop button.

Switches and function settings are all designed in this area.

1.3. Electrode fixing box (3)

The fixed electrode box is welded with 10mm high-quality steel plate, and the front and rear two doors are detachable.

1.4. Electrode moving box (5)

The electrode moving box can be stopped at any position, used to adjust the clamping distance, and has a parking lock function;

1.5. Magnetic suspension stirring and spraying system (6)

The equipment is designed with a separate magnetic suspension tank with a V-shaped structure at the bottom and a stirring spray electric pump installed on the upper part. This part is connected to the sump tank with a hose, and a manual spray gun is installed on the front side of the sump tank.

The system has strong stirring, the V-shaped structure ensures that the magnetic powder is not easy to precipitate, and the spray pressure is adjustable;

The capacity is 20L;

1.7. Magnetization and demagnetization power supply system:

The equipment adopts AC magnetization method, which is two sets of independent magnetization power supplies. The two main transformers provide the magnetizing current respectively. The controllable module converter technology is used to control the current of the circuit, and the isolated voltage is sent to the electrodes and coils. The size is continuously adjustable and the corresponding instrument indication is set. The current can be preset, and the alarm will be alarmed when the preset current is insufficient or exceeded to prevent misdetection and missed detection, and ensure that the workpiece obtains the specified magnetization intensity. AC with power-off phase control function to maintain stable residual magnetism, which can be used for residual magnetism flaw detection.

With AC attenuation method demagnetization function.

The material of the current path: all red copper bars or copper cables.

1.8. Electrical control system:

1) The electrical control system is controlled by OMRON PLC, including controllable modules and their protection devices, current adjustment trigger devices, ammeters, control buttons and indicator lights, cylinders, triples, solenoid valves, pressure regulating valves, air switches, intermediate relays, Control devices such as AC contactors. Main power circuit breaker with overload protection.

2) Man-machine interface control system:

The computer (human-machine interface system) controls the magnetization current, magnetization time, magnetization, etc., which greatly improves the detection accuracy, and can automatically complete the step-by-step operation of magnetization, magnetization current preselection, and tracking.

The touch screen programmable display communicates with the PLC programmable controller through an adapter to directly display the key parameters of the system. And set the authority password, and the parameters can be adjusted within the authority. Screen design: Homepage-company name. Any touch can enter the main screen-"Main Menu", "Work Page", "Alarm Record", "Precautions", "Current Waveform", touch each function key to automatically switch to the corresponding screen, and the process parameters of various typical workpieces Can be stored.

The magnetizing current can be preset, and the automatic tracking circuit is formed through the touch screen programmable display system, and the error between the preselected value and the actual passing current value is ≤±3%.

The system has fault self-diagnosis function. Over-current, under-current, abnormal air pressure, excessive temperature rise of the main circuit, sound and light alarms and automatically stop working.

3) The equipment shell is grounded reliably, and the insulation resistance of the whole machine is ≥2MΩ.

4) The equipment has complete safety protection and interlocking and alarm functions.

5) The electrical schematic diagram, wiring diagram and the actual circuit of the equipment should be completely consistent.

6) The PLC contact is equipped with an intermediate relay to protect the contact.

7) The wiring of each electrical component is required to be marked with a wire number, and the wiring between each component is provided with a wire slot board.

2.Main technical parameters (Note: HWDC is the abbreviation for half-wave DC)

*AC magnetizing current:

Circumferential 0-500A continuously adjustable, with power-off phase control

Vertical 0--1000A (1000A*6T=6000AT) continuously adjustable, with power-off phase control

*Control method: pre-selection and automatic compensation

*Compensation refresh rate: 0.02S/time

*Temporary load rate: ≥25%, suitable for continuous 7*24H work

*Demagnetization effect: ultra-low frequency DC commutation attenuation demagnetization, remanence ≤0.2MT, adjustable demagnetization frequency

*Magnetization method: circumferential magnetization and longitudinal magnetization, circumferential and longitudinal composite magnetization

*Weekly longitudinal current error rate: ≤±3%

*Stroke: 0-200mm

*Coil inner diameter: 100mm

*Power supply: AC380V±10% 50HZ 40KVA (instantaneous 5S), three-phase five-wire system.

*Size: length 1400*width 600*height 750

*Sensitivity: A type (QQI) sensitivity test piece (30/100) full circle and cross can be clearly displayed.

*The Aviation Industry Standard of the People's Republic of China HB/Z72-1998 "Magnetic Particle Inspection"

*Meet the JB/T8290-2011 standard of "Magnetic Particle Flaw Detector" of the Ministry of Machinery Industry, and the industry HB/Z72-98 standard.

3. Accessories

| No. | Name | Quantity | Explanation |

| 1 | Magnetic Particle Flaw Detector | ||

| 1.1 | Magnetized power system | 1 set | Circumferential:0-500A Vertical:0-1000A |

| 1.2 | Intelligent closed-loop control | 1 set | 1 set man-machine interface touch screen |

| 1.3 | Operation control system | 1 set | |

| 1.4 | Clamping, energizing | 1 set | |

| 1.5 | Magnetic suspension recovery,stirring mechanism | 1 set | |

| 1.6 | Foot switch | 1 set |