Add to Cart

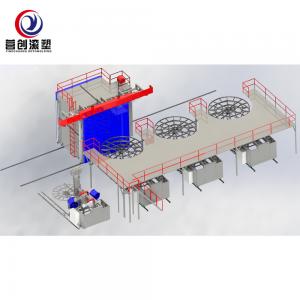

operating platform 4m automatic shuttle rotational molding machine For Sales

Equipment advantages:

1, the oven adopts a circular oven structure, the space utilization rate is high, and it is more energy-saving.

2, the oven uses a fabricated structure, an oven is divided into 4 or 5 and 6 pieces of assembly

3, the heating method adopts the principle of hot gas going up, heating faster, high efficiency, more energy saving

4, the burner is imported from the Italian Liya Road brand

5, control system Siemens S7-1200 network cable communication method to collect data, reduce the problem of conventional lines, the line laying more beautiful

6, Yingchuang Rotomolding Equipment Co., Ltd. accepts the personal customization and design of all customers, and determines the final needs of customers according to the needs of customers, so that customers are satisfied, we can rest assured

Equipment history:

The industry was semi-revolutionized about 15 years ago when Italian machinery maker Persico introduced the Leonardo, the world’s first completely automated rotomolding system; but in North America, only a handful of the expensive machines, with highly engineered molds, have been sold, and those to companies producing high-volume parts. In 2013, Persico unveiled the Smart system, which it billed as a more flexible, but still automatic, rotomolder.

The most common types of molds used in rotomolding are cast aluminum, fabricated aluminum, and steel and stainless steel. “Historically, almost all rotomolds were cast aluminum made in a foundry or sheet-metal molds,” said Bruce Muller, president of Plastics Consulting Inc., a rotomolding specialist based in Palm City, Fla. “The acceptance of CNC molds has grown lately, especially in Europe. These molds are stronger, have a longer life, conduct the heat faster, and potentially offer more precision.”

And the most common type of material to be rotomolded is PE, hands-down. “Ninety per cent of all rotomolded parts are made from PE,” Muller said. “The rotomolding process is relatively long and therefore aggressive on polymers, and only PE and a few other resins — including PVC (plastisol), nylon, PP, Hytrel, PC, and cross-linked PE — are suitable.”

Since most rotomolding parts are generally not mechanically conveyed away from the mold, there is very little post-molding equipment necessary. Before loading the mold is a different story, however. “Since rotomolding primarily uses powder instead of pellets, it requires an additional piece of equipment to pulverize the resin,” Muller said. “This can be done by the resin supplier or in the rotomolding plant.” On a rel

Specifications:

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

More Details