Green 750ml Bottle Manufacturing Equipment For Wine

Add to Cart

300ml, Amber Bottle Making, Glass Bottle Production Line, For Beer Bottle

1. Brief introduction

Glass is a special amorphous inorganic nonmetallic material. The main component is silicate, a non-crystalline solid with an irregular structure.

With a good chemical stability and excellent artistry, the glass container has become one of the most popular packing materials. It is also extensively applied in food and beverage industries, which has occupied an important position in the market that cannot be ignored.

Glass melting is the most important process in glass production, it is a forming process where the batched materials form a qualified liquid evenly with no bubbles under high temperature heating.

The melting process is divided into five stages as following, each section has its inner connection, affecting each other. If one stage has imperfect performance, it will influence the next stage, and ultimately affect the quality of glass.

The defect of glass production is mainly due to the melting process, the melting quality has a close relationship with the quality of yield production, production cost, fuel combustion, furnace campaign, etc. It is important to ensure the physicochemical reaction of batched materials perform well during the whole melting process, and make sure the whole process is smoothly operated and for manufacturing high quality glass products.

2. Types of container glass classification

- Sort by body shape:

| Item | Description |

| 1 | Container / Bottle |

| 2 | Container with handle |

| 3 | Tubular container |

| 4 | Volume: 1ml~25000ml |

- Sort by bottom shape:

| Item | Description |

| 1 | Roundness (majority) |

| 2 | Oval |

| 3 | Square |

| 4 | Rectangle |

| 5 | Flat |

- Sort by diameter of bottle neck:

| Item | Description |

| 1 | Wide-mounth bottle or jar |

| 2 | The inner diameter of the bottle is over 30mm, with small or no shoulder, which is usually used for semifluid and powder or bulk solid goods. |

| 3 | |

| 4 |

- Sort by bottle mouth and caps:

The diameter and tolerance of bottle mouth is a standard one. The bottle mouth can be divided into screw, cork, pouring, crown cap, roll-on cap, plastic cap, spray mouth, press type mouth, prize up mouth, glass stopper frosted mouth, mouth with handle and tubular type mouth, etc.

- Sort by requirement of use:

| Item | Description |

| Single use bottle | Used once and discard it. |

| Recycle bottle | These products can be recycled and reused many times |

- Sort by forming type:

| Item | Description |

| Form by mould | The glass liquid will be form a certain type of bottles via mould |

| Form by tubular method | The glass liquid will be stretched into a glass tube and re-manufactured to a required bottle. |

- Sort by color:

| Item | Description |

| Flint / Clear | Most of the glass containers are flint, which will keep stores more visually. |

| Green | Usually, the green bottle is used for drinks and beers. |

| Brown / Amber | Normally, the brown bottle is for pharmaceuticals or beers, this kind of color can absorb ultraviolet rays, which will help to protect the stores. |

| Opal | This kind of bottle is for cosmetics, vanishing cream, unguent and liquor. |

- Silicate forming

- Glass liquid forming

- Clearing

- Homogenization

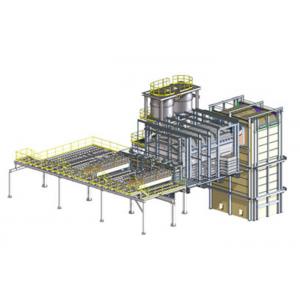

4. Main equipment of glass forming

- Gob Feeder / Serve Gob Feeder

- I.S. machine

- Press machine

- Blowing machine

- Stacker

- Transfer ware

- Conveyor

- Annealing lehr

- Packing devices