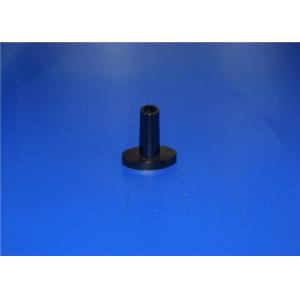

Black Zirconia Ceramic Parts Flame Resistant Zirconia Injection Molded CE

Add to Cart

Flame Resistant Zirconia Injection Molded Black Zirconia Ceramic

Parts

Chemical resistance・・・It’s noble for acid and alkali.

Wear proof・・・It has good wear proof as high hardness alumina.

Accuracy of dimension・・・We can finish as customers order accuracy

by centere less grinding.

Surface roughness・・・We are able to shape until mirror surface.

shape・・・D cut,joggling, and more..We are able to arrange for all.

Delivery・・・We have stock all the time.

Zirconia oxide has the highest strength and toughness at room

temperature of all the advanced ceramic materials. The fine grain

size allows for extremely smooth surfaces and sharp edges.

Applications include scissors, knifes, slitters, pump shafts,

metal-forming tools, fixtures, tweezers, wire drawing rings,

bearing sleeves and valves

Ortech provides state-of-the-art materials manufactured by the most

cost-effective processes. Ortech Zirconia oxide maintains efficient

manufacturing facilities that support quick-turn prototype

development and high volume production.

Mingrui ceramic manufacture and provides alumina ceramic components for a wide range of application like Mechanical Equipment, Electronic & Electrical, Oil Drilling, Medical, Chemical Industry etc. According to actual application and customer's requirement, the purities vary from 95%-99.7% and the forming methods will be different. The forming methods applied in our plant include dry pressing, isostatic pressing, injection moulding, extrusion moulding. With experienced engineers and talented workers, we are confident to offer high quality, high precision, complex components for customers worldwide.

Product Description

Mingrui Ceramics has years of experience designing and developing

technical ceramic solutions for a wide variety of applications and

industries. Anti-chemical Corrosion Zirconia Ceramic Parts Chemical

Stirring Rod. We offer this expertise to all of our customers to

ensure the best design and materials are chosen for their specific

application and needs. Anti-chemical Corrosion Zirconia Ceramic

Parts Chemical Stirring Rod, Typically, our custom technical

ceramic components and parts we supply are used for one of three

main reasons:

High temperature ceramics – crucibles, nozzles, lasers, furnace/kiln fixtures

Wear and corrosion resistant ceramics – plates, housings, gages,

caps/lids

Electrical insulation ceramics – contact blocks, standoffs, fasteners, spacers

Mingrui Ceramics is one of the world’s premiere technical ceramic

suppliers – contact us to see what technical ceramics we can create

for you.

Dongguan Ming Rui Ceramic Technology Co.,ltd is a professional

manufacturer which is specialized in zirconia ceramics. We have 10

senior engineers and lots of technologists; our ceramic products

are precision ceramic structure parts used mainly in industrial

field, which is made of strengthened structure zirconia ceramic.

Our products including strengthened structure zirconia

ceramic,ceramic bar,ceramic tube,ceramic shaft,ceramic

plate,ceramic sleeve,ceramic valve,ceramic plunger and ceramic arm.

The product we produced are applicable to Instruments,Medical

instrument,Clocks and Electronic Products,Mills,Energy and

Power,Machine and Metals,Autocar and Military and some other high -

end areas.

Dongguan Ming Rui have achieved great successes in particular

requirements which is based on cooperating with Tsinghua University

and professional knowledge and business experience by ourselves. We

get the low-budget and high-performance new ceramics products from

the high – quality raw materials and composite technology and

precision processed, technical and value are increasing strongly.

In professional technology, innovation, sincerity, sustainable

development, offering the high efficiency products, perfect

service, good reputation. By the way, our company have an unique

technical called “mirror polishing” which is improved our products

bright,color,smooth and made our product better than other

competitors.

Warmly welcome all the customer form the world to visit our

company!

Properties sheet :

| Manufacturing Options | Advanced Finishing Services |

| Injection molding | Precision grinding and lapping |

| Roll compacting | Laser machining |

| Extruding | Engineering design and support |

| Co-firing | Metallizing |

| Isostatic pressing | Ceramic-to-metal brazing |

| Dry pressing | Specialized coatings |

| Hot pressing | Threaded components |

| Tape casting | Precision motion components |

| Slip casting | Complex clean room assemblies |

More photos :