Add to Cart

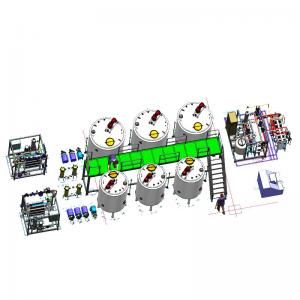

3000L/H condensed milk plant from fresh milk processing with 380g tin can packages

| Brand Name: | Shanghai Beyond |

| Model Number: | BY-CD1000L |

| Capacity | 5-200TPD |

| Raw material | Fresh cow milk, buffalo milk, goat milk, camel milk or milk powder, or both mixed |

| End product | sweeten condensed milk/un-sweeten condensed milk |

| Shelf life | 6months, 12months (keep at room temperature ) |

| Main material for machines | SUS304 or SUS316 |

| Package for end product | stand pouch / tin can/plastic tub etc. |

| Certification: | ISO9001/CE/SGS |

| Place of Origin: | China |

| Manufacturer history | More than 10years |

Description:

Shanghai beyond machinery co., ltd is specialized in supplying various kinds of milk processing line, including the pasteurized milk, UHT milk, flavored milk, yoghurt, cheese and butter, cream, condensed milk etc.

Shanghai Beyond can supply complete turnkey projects for customers, integrating with designing, equipment manufacturing, to installation and commissioning and also training the operators.

UHT milk process: milk transporting tank or vessels, milk filter and collection tank; cooling and storaging tank(milk chilly tank), Mixing/Blending and milk standardization, cream separation, UHT sterilizer(tubular type or plate type) homogenization, degassing, and filling

Features and advantages:

1. Processing capacity can be ranged from 2T/Day to 1000T/Day.

2. High standard design, manufacture and project installation requirements, which guarantee the first-class finish products in the dairy processing line.

3. PLC control the whole production line, saving labor force and facilitate production management.

4. Full-auto CIP cleaning, to ensure whole production line equipments meet food sanitary safety requirements.

5. Whole line with features as high level automatic, low labour intensity, easy operation, safe function and low operation cost.

6. Whole line adopt sanitary design, can be cleaned thoroughly, with high level sanitation.

| NO. | FLOW NO. | NAME | SIZE | MAIN TECHNOLOGY PARAMETER | UNIT | QTY |

| 1 | A | Hot water Unit | ||||

| 2 | A-1 | hot water tank | V=3000L | made of sus304 stainless steel, insulated with PU,with airtight manhole, cone top and bottom cover, ladder, glass tube level indicator | set | 1 |

| 3 | A-2 | hot water pump | Q=5T/h | SUS304 stainless steel,pump lift 36M,mechanical seal | pcs | 1 |

| 4 | A-3 | plate heater | Q=5T/h | plate heat exchanger is made of sus304 stainless steel section, with plastic seal | set | 1 |

| 5 | A-4 | temperature control system | Q=5T/h | Imported brand pressure reducing valve, adjusting and drain valve, JUMO temperature sensor, Domestic brand good quality steam stop valve, pressure gage | set | 1 |

| 6 | Subtotal A | |||||

| 7 | B | Ingredients Preparation UNIT | ||||

| 8 | B-0 | Blending tank | 100L | SUS304 stainless steel, single layer, ,airtight manhole, breather valve, digital readout thermometer,anti-eddy baffle, supporters with adjustable feet | pcs | 1 |

| 9 | B-1 | Blending tank | 2000L | SUS304 stainless steel, double layers, with PU heat insullation,off-center vertical agitator, high speed shearing, conical head, airtight manhole, breather valve, digital readout thermometer,anti-eddy baffle, supporters with adjustable feet | pcs | 3 |

| 10 | B-2 | Centrifugal pump | Q=10T/h | SUS304 stainless steel,pump lift 36M,mechanical seal | pcs | 1 |

| 11 | B-3 | Mini set of tubular-type heat exchanger | 10T/H | SUS304 stainless steel, single stage, T1=35°C, temperature automatic control,Spriax Sarco steam control system, JUMO temperature sensor | PCS | 1 |

| 12 | B-4 | High speed dissolving machine | Q=10T/h | Main material SUS 304, self-sucking pump, emulsification pump, with feeding platform | pcs | 1 |

| 13 | B-5 | Centrifugal pump | 3M/H | SUS304 stainless steel,pump lift 36M,mechanical seal | PCS | 1 |

| 14 | B-6 | Duplex filter | Q=5T/h | SUS304 stainless steel, 100 Mesh | pcs | 1 |

| 15 | Subtotal B | |||||

| 16 | C | Pasteurizing unit | ||||

| 17 | C-1 | Plate type pasteurizer | 2T/h | SUS304 stainless steel, inlet temperature 60C, homogenizing, pasteurizing at 90C, 30S holding, outlet temperature 70C/30C, PID semi-auto control, include Spirax Sarco steam control system, milk balance tank, milk pump, plate heat exchanger, pipes and valves, frame and support, electrical control box etc., | set | 1 |

| 18 | C-2 | High pressure homogenizer | 2T/h | working pressure; 20MPa,(starting box included) | pcs | 1 |

| 19 | C-3 | Temporary storage tank | 2000L | SUS304 stainless steel, double layers, heat insulated, agitator, conical head, airtight manhole, breather valve, digital readout thermometer,anti-eddy baffle, supporters with adjustable feet | Set | 2 |

| 20 | C-4 | Centrifugal pump | 3T/H | SUS304 stainless steel,pump lift 36M,mechanical seal | PCS | 1 |

| 21 | Subtotal C | |||||

| 22 | D | Concentration UNIT | ||||

| 23 | D-1 | Coil pipe evaporator | 1000 model | SUS304 material, water evaporation capacity 1000LPH, coil pipe heating, water injection vacuum pump, CIP cleaning ball | Set | 2 |

| 24 | D-2 | Screw pump | 5T/H | SUS304, outlet pressure 0.6Mpa | Set | 1 |

| 25 | D-3 | Temporary storage tank | 2000L | SUS304 stainless steel, double layers, heat insulated, agitator, conical head, airtight manhole, breather valve, digital readout thermometer,anti-eddy baffle, supporters with adjustable feet | Set | 2 |

| 26 | D-4 | Rotor pump | 1T/H | SUS304 stainless steel, mechanical seal, outlet press 0.6MPa,frequency control of motor speed | PCS | 2 |

| 27 | D-5 | High pressure homogenizer | 1T/H | SUS304 stainless steel, 20MPa, including starting cabinet | 1 | |

| 28 | D-6 | Plate cooler | 1T/H | SUS304 stainless steel, ice water cooling, 60-30C | 1 | |

| 29 | subtotal D; | |||||

| 30 | E | Temporary storage & Crystallization Unit | ||||

| 31 | E-1 | Crystallization tank | 1000L | SUS304, horizontal type, PU insulation, cooling jacket, vertical scrapper agitator, digital thermometer, adjustable legs. | PCS | 3 |

| 32 | E-2 | Screw pump | 1T/H | SUS304, outlet pressure 0.6Mpa | PCS | 1 |

| 33 | E-3 | End product tank | 5000L | SUS304 stainless steel, PU insulation, conical head, sealed manhole, breathing valve, digital show thermometer, plate anti vortex, adjustable legs | PCS | 1 |

| 34 | E-4 | Screw pump | 1T/H | SUS304, outlet pressure 0.6Mpa | PCS | 1 |

| 35 | E-5 | Drying Oven | Electric heating oven, used for heating the seed crystal. | PCS | 1 | |

| 36 | E-6 | lactose crusher | crushed granule sizes;5um | PCS | 1 | |

| 37 | Subtotal E | |||||

| 38 | F | Filling unit | ||||

| 39 | F-1 | tin can filling machine and the afterwards system | 100 Cans/min, 170g/can, full automatic touch screen control, this system includes; auto filling and seaming machine, unpaper, conveyor, drying machine, date printer, etc. | PCS | 1 | |

| 40 | F-2 | conveyor | SUS304 stainless steelcal, culate by 100 meters, include drive motor and control box | set | 1 | |

| 41 | F-3 | spraying type sterilization system (retort) | ¢1500*L4250 | full-auto controlled by PLC,touchscreen,recorder without papaer,SUS304,safty device, steam & water mixer, temperature auto controlled and can be adjustable between 80-135 degree | set | 2 |

| 42 | F-4 | automatic retort crates loading machine | 6000 bottles/h,300ml/bottle, 6000 bottles/h,300ml/bottle, use MITSUBISHI PLC programmable controller, Sick photoelectric switch, SCHNEIDER over travel-limit switch, SIEMENS contactor and so on. | set | 1 | |

| 43 | F-5 | automatic crates unloading machine | 6000bottles/h,300ml/bottle, use MITSUBISHI PLC programmable controller, sick photoelectric switch,SCHNEIDER overtravel-limit switch,SIEMENS contactor and so on. | set | 1 | |

| 44 | F-6 | guide way for bottle carrier baskets | use SUS304 angle steel as the wheel guide path, carbon steel as reinforce plate, angle side with welding 14×14mm, 5mm thick Aluminum Sheet between angle steel lay, support legs are 2×50×50mm sus304 stainless steel tubes, the rest material is 1.5×38×38mm SS304 stainless steel pipes | set | 1 | |

| 45 | F-7 | Heat- Resistance plastic clapboard | 8mm heat resistance plastic sheet with holes | set | 1 | |

| 46 | F-8 | electrical drive cart | transport trolley for the bottle carrier baskets to move back and forth, there are stainless steel guide plate as transition in the direction of the bottle carrier baskets enter into retort and come out , machine frame using carbon steel structure, 5mm aluminum checkered plate covered on the surface | set | 1 | |

| 47 | F-9 | guide path for cart | I-shaped carbon steel guide path, carbon steel structure frame, foundation use wheel and axle connection, with brake reduce motor, with frequency convertible step less reduce electrical box, four-core sheet copper electric brush guide path, plastic external cover, with conductive chain wheel cart, whole journey with carbon steel support and carbon steel bridge, with electric brush guide path | set | 1 | |

| 48 | F-10 | manual rotary plate | 90 degree guide path cart turn plate;¢1200mm,round plate is made of 12mm carbon steel plate, carbon steel structure frame, 5mm aluminium checkered plate covered on the surface | set | 1 | |

| 49 | F-11 | floor around baskets loading and unloading machine, and operation platform | 5mm aluminium checkered plate covered on the surface; 50×50mm spray-painted carbon steel square tube as supporters | set | 1 | |

| 50 | F-12 | bottle carrier baskets | 2mm stainless steel sheet without holes on all around, 4mm ×40mm stainless steel sheet for reinforce, 50mm×50mm stainless steel angle steel all around | set | 1 | |

| 51 | F-13 | baskets bearing plate | 30X30X3mm stainless steel square tubes, 2mm stainless steel plate with holes | set | 1 | |

| 52 | F-14 | Bottle drier | side plate of box is 2mm SUS304 stainless steel plate, frame is SUS304 stainless steel, high power fan, big power air hose, inside has stainless steel air spout port | set | 2 | |

| 53 | F-15 | Ink jet printer | spray ink Printing | set | 1 | |

| 54 | F-16 | conveyor and lubricating system | with lubrication liquid barrel, with measuring pump | set | 1 | |

| 55 | Subtotal J; | |||||

| 56 | G | CIP system | ||||

| 57 | G | Semi-auto CIP system | 4×3T | SUS304 stainless steel material, double circuit, four tanks structure, semi-automatic, double layers Acid and alkali tanks with PU insulation , with off-center vertical agitator, electrode type high and low liquid-level meter, single layer clean water tank, with ball float type liquid meter, proceed pump, Concentrated acid/alkali tank adding system based on US technology, Spirax Sarco steam control system, Germany Jumo temperature sensor, plate heat exchanger, 300L×2 acid/alcali Concentrate tanks, material SUS 316, stainless steel electric control cabinet, Schneider electric components | set | 1 |