Add to Cart

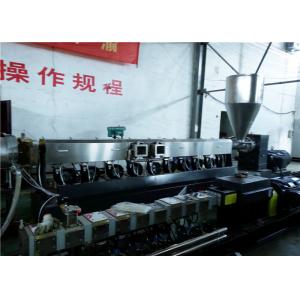

800kg/hr single screw extruder with strand pelletizing system for PE flakes recycling

Company Advantages:

1. Quick response to your requirement

2 Different combinations according to your application.

3. Professional R&D,production,sales and service

4. Rich experience on the twin screw extruder. Will help you to do

the project perfectly

5. All machine will be produced under our QC standard.

Advantages of the high efficiency single screw extruder:;

Comparing to normal single screw extruder, We have greatly improved the screw design and know-how of the single screw extruder, making the capacity almost double then normal single screw extruder, while the energy consumption is much less. This not only increases the efficiency of extruder itself, but also save production cost for end-users.

Advantages:

Modular Single Screw Design

To solve the problem of some abrasive material processed by single screw, We have originally innovated modular single screw extruder. The whole screw is composed by small pieces of different screw elements like twin screw extruders. With this new design, customer doesn’t have to change the whole screw if it is worn by aggressive materials, instead, you just need to change some pieces of the screw elements where is seriously worn. This will save your cost too much.

The other advantage of this modular screw design is, since the screw is modular like twin screw, then we can install different pieces with different functions. This will help you to get a better plasticization and dispersed products.

Main Application :

Specification of the extruder:

| No. | Description | Quty |

| 1..0 | Raw material dealing system | |

| 1.2 | Hopper with magnet | 1 |

100L stainless still hopper With magnet throat With sight glass on the hopper | ||

| 2.0 | Extrusion units | |

| 2.1 | CSETM 120 single screw extruder | 1 |

Screw diameter:φ120mm L/D:32:1 Rotation speed:0~120rpm Motor power:132Kw,SIEMENS BEIDE AC motor,SCHNEIDER frequency inverter with global guarantee Power transmission:nylon coupler Gearbox: The gear box of the main extruder is combined with the torque distributing part and has a parallel three shafts design which are tightly in structure. The reducing, torque distributing and the two output shafts are all from NSK The gear is high load hard gear face and gear shaft is made of 20CrMnTi,surface is nitrified processed,HRC56~60. Output/input ratio:1500/120rpm The safety cover needed for the gear shaft. Airproof ring is imported Screw:made of 38CrMoAlA,nitrified process,depth0.5-0.7mm hardness 950-1100HV,brittleness I grade Barrel: 38CrMoAlA, Nitrified process, depth 0.5-0.7mm,HV1000-1050 Venting ports will be on the middle and end of the barrel The barrel is cooled by air blower. 0.55kw | ||

| 2.2 | Vacuum pump | 1 |

Motor power: 4kw Vacuum degree: 0.08Mpa With vacuum pot, vacuum gauge, and all related equipments. | ||

| 2.3 | Hydraulic screen changer | 1 |

Structure Mode: Plate type Driving Mode:Hydraulic Action Time: <1S; Driving Mode: Hydraulic Station The hydraulic station includes: Driving Oil Pump1.5kw, Highest pressure20Mpa, with safety valve, accumulator. The inspection on pressure and temperature: Set one inspection position before the screen and display the melt temperature. Heating power:4kw, cast-Al heater Accumulator6.3L Filtering area:6400 mm^2 | ||

| 3.0 | Water ring pelletizing system | |

| 3.1 | Extrusion die | 1 |

Extrusion plate: 40Cr. No.of holes: 40holes, 35holes Size of hole: 2.8mm and 3.2mm | ||

| 3.2 | Water ring pelletizer | 1 |

Using pure water Driving power: 4kw Capacity: 500-800kg/hr; With water ring cover and pipelines Stainless steel made | ||

| 3.3 | Water circulating system | 1 |

Motor: 5.5kw With heating exchanger, pipe type Volume of water chamber: 800L With filter screen for big size | ||

| 3.4 | Centrifugal dryer | 1 |

Motor power:5.5kw 304 stainless steel made With blower, filter, stainless steel barrate Volume: 800L Capacity: 400-800kg/hr | ||

| 3.5 | Vibrator | 1 |

Motor Power: 2x0.37kw Capacity:400-800kg/hr Discharging Gap: 3, qualified pellets, huge pellets, small pellets Made of stainless steel | ||

| 3.6 | Air blower and silo | 1 |

Blower motor power:4kw; Pipe collected with clamps for easy disconnected Silo: 1000L Made of stainless steel with support frame | ||

| 4.0 | Electric cabinet | 1 |

Low-voltage electrics: SCHNEIDER; Speed regulator: SCHNEIDER inverter; Temperature control panel: RKC from Japan Switches: Schneider With safety switch on the cabinet |

Model of Single Screw Extruder:

Service:

Before-sale

Introduce products and applications detain

Recommend suitable solution

Provide with reference in formation

Offer lab for test

During manufacturing

Provide with layout and engineering conditions

Inform the project processing status

Offer other documents

After-sale

Provide with installation ,commissioning and training

Register and record customer information

Offer spare parts

Provide with necessary technical support for new application

Visit customer regularly and correct information

Picutres: