Cigarette Package Medium Wave Drying Machine , Silk Screen Machine 70% Energy Consumption Saving

Add to Cart

Allfine Group-20 years experience Solution

1:Label production line- flexo print machine,die cutting

machine,slitting machine,inspection and rewinding machine

2:Flexible package line-water bottle label PVC,heat transfer Pet,

Opp, Pe etc rotogravure printer, dry laminator, PP PE film blowing

machine,bag making machine

3:Decal paper,wine and smoking package-Silk screen press machinery,

wicket dryer, uv dryer

4:Paper cup production line- flexo printer. die cutting machine,

paper cup making machine

1: Save material 2: Improve efficiency 3:Professional tranning 4: Factory built

Partner Manager-Jack Huang

Allfine Group

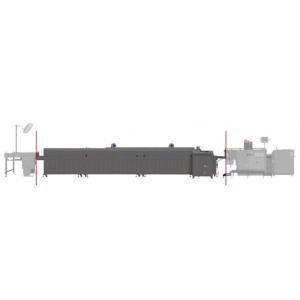

LC800ZB Medium Wave Oven machine/Medium wave dryer/Medium wave drying machine paper cigarette package wine package label

screen printing production line.pdf

LC Series Medium wave dryer can match with Full automatic screen press as a complete production line.

1. Can drying various inks fast.

2. Widely used in paper cigarette package wine package label plate advertising plastic printed circuited boards and other printing industry.

3. Multi-section combination design, according to the printing material and ink the combination be freedom of choice .

4. The standard configuration is of two section of Medium Wave Near Infrared(IR),one section of cold air cooling ,customer can increase or decrease in any combinations by actual demand.

5. Multi-section combination design, according to the printing

material and ink the combination be freedom of choice .

6. The standard configuration is of two section of Medium Wave Near

Infrared(IR),one section of cold air cooling ,customer can increase

or decrease in any combinations by actual demand.

| Characteristic |

| 1. Using the high-capability Medium Wave IR lamp,the characteristic

are as below: 1).Fast temperature rising, the start-up time is 1second,easy to control the heating temperature; 2).High thermal efficiency, with light radiation effection, without heating the air. In the same temperature, the output power is 5 multipe relative to other IR lamps . 3).Long service life, durable using, average lift is 20000hours; 4).The Medium Wave radiation heating, drying the inks from the botton layer to the outer surface, achieve the best drying effect, and compared with the traditional models can save more than 70% energy consumption. |

| 2. Bran-new temperature control mode, using the composite reflective insulation board, greatly save energy consumption |

| 3. Favorable hot air circulation and exhaust system, make each part of the drying chamber of uniform temperature, improved the drying quality,and can eliminate the waste exhaust gas generated in the drying process, shorter the drying section, save the energy. This can be custornized by material's characteristics. |

| 4. Each group of lamp can be separated control, all have been interlocking with the delivery belt(lamps will not power on if the delivery belt is stop,prevent the belt),ensure the production is moving in the stable drying temperature. |

| 5. All parts of the machine is full of the nozzles, which can accurately calculating the shape and position, airflow all focused on the substrate's surface, achieve the best uniform effect, also can ensure to convey the tissue paper smoothly. |

| 6. TEFION delivery belt, high temperature resistance, friction resistance, ensure the use life. |

| 7.Whole machine's delivery belt is with rectify device, ensure delivery smoothly. |

Video: please contact me for the mp4 machine operation

Ruian Allfine Machinery Co Ltd professional in Flexo Printing Machine,Auto Die Cutting Machine,Auto Slitting Machine, Rotogravure Printing Machine, Dry and Solventless Laminating Machine, Inspection and Rewinding Machine, Film Blowing Machine, Bag Making Machine, Screen Printing Machine, Window Patching Machine and other Auxiliary Products. With years of manufacturing experience and high technology.

After the machine delivery to customer’s factory, we will sent engineers or technician to client’s factory, within the appointed time to install the machines and train the operator for buyers. Engineer’s salary and transportation fee from our factory to the domestic airport or station is on our account.

During the installation, customers should offer Accommodation,Round-trip tickets, Visa cost for our engineers. working time is 8 hours per day. Salary is 80-150USD per day( it depends)