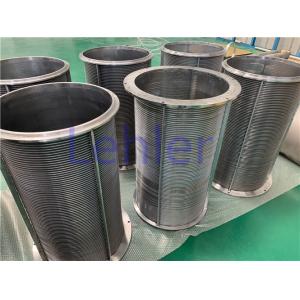

Waste Water Treatment Wedge Wire Screens 200 Micron Slot 360 X 660mm

Add to Cart

Ti material Wedge Wire Screens, Vee-shaped wire screen for waste water treatment

1. Wedge Wire Screen is characteristic of accurate cut size and precise gap (aperture) required with the ability to carry heavy loads.

The working surface is 100% smooth which eliminates blinding and pegging.

Wedge Wire Screen is produced through the method of electric resistance welding,

wires with special profiles are welded to supporting wires at 90 degrees.

The distance between the surface profiles is controlled very accurately as it forms the slot through which the filtrate flows.

The direction of the flow is determined by the position of the surface profiles in relation to the support profiles.

Wedge wire screens are either flow-out-to-in OR flow-in-to-out.

2.Specification of Wedge Wire Screen?

| Profile wire | Support rod |

| 0.76x1.5mm | 2.0x3.0mm |

| 1.5x2.5mm | 2.0x3.0mm |

| 2.0x3.0mm | 3.0x5.0mm |

| 2.0x4.0mm | 3.0x5.0mm |

| 2.5x3.0mm | 3.0x5.0mm |

| 3.0x5.0mm | 3.0x5.0mm |

| 3.0x6.0mm | 5.0x8.0mm |

3.Details pictures of Wedge Wire Screen:

4. Application of Wedge Wire Screen?

Wedge Wire Screen is widely serviced for many industries for filtration and separation stage.

environmental protection

food & light industries

pharmaceutical

water treatment

pulp & paper

paint & inks

petroleum

chemical

5. Advantages of Wedge Wire Screen?

- Non-clogging construction: The v-shaped wires and support rods is welded together by automatic resistance welding, which ensures a two- point contact between the particles and the slot,which minimizes clogging of near size product.

- Strong construction: for most applications the wedge wire is self-supporting because of the welding at each intersection and can therefore withstand high pressure(Psi) and heavy loads.

- Smooth Surface Filtration: very good smooth filtration surface, which reduce mechanical wear.

- High-precision slot opening: Minimum Slot opening is 20 microns.