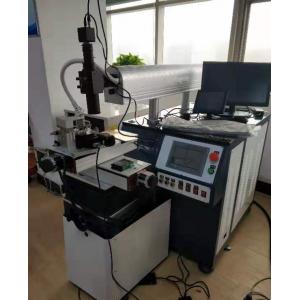

Metal Aluminium Laser Cutting Welding Machine / Copper Auto Welding Machine

Add to Cart

Metal Aluminium Laser Cutting Welding Machine / Copper Auto Welding Machine

Product Description:

MOPA fiber laser welding machine,uses the MOPA structures,ytterbium doped fiber laser by using vibration mirror control system

is a new type of laser welding machine to high speed welding.Minimal energy fluctuation ,welding high stability.

Product Features:

1. Pulse width and frequency adjustable ,different parameters can be selected according to different materials,and single pulse energy can

reach up to 1.2mJ.

2. Non-contact spot welding,fast speed and minimal thermal influence.

3. Using the optical fiber laser marking machine interface,the welding figure is easy to eidt.

Technical Parameters:

| Model Number | HYY-F70W | HYY-F120W |

| Maximum laser power | 70W | 120W |

| Single pilse maximum energy | 90J | 100J |

| The laser wavelength | 1.06µm | 1.06µm |

| Laser Welding Frequency | <=50HZ | <=50HZ |

| Laser Welding Depth | <=0.2MM | <=0.3MM |

| The pulse width | 0.5-20ms | 0.5-20ms |

| Control system | CNC2000 | CNC2000 |

| Standard table travel | 300*200mm | 300*200mm |

| Positioning system(GPS) | Microscope CCD | Microscope CCD |

| Power demand | 220V/50H/40A | 220V/50H/40A |

| Cooling mode | Air cooling | Air cooling |

| The whole machine consumes power | 500W | 600W |

Application:

It is mainly applied to the superposition welding of the same metal and foreign metal.

Such as Aluminium-copper.Copper-aluminium,Aluminium-aluminium,Copper-copper,Nickel-aluminium etc.

Installation environment requirements

1. Prevent vibration: The optical path of the laser welder is very precise, so the working environment must be stable. If the working environment is vibrating, the optical path of the laser welder will change, and the welding effect will be directly affected!

2, reduce dust: Because the laser equipment has a lot of optical components and sophisticated electronic components inside, so to prevent dust from adsorbing on the laser and those optical lenses, affect the quality of light.

3. Voltage standard: The voltage of the laser welding machine must

be in strict accordance with national standards, and the voltage should not have large fluctuations. If voltage fluctuations are recommended to install a voltage regulator, the working environment is recommended to stay away from high-powered equipment.

4, good grounding: only correct, good grounding can make it work properly, laser power supply, welding control system are using industrial microprocessor for digital control, only good grounding can ensure their normal and stable work.

Packing Way:

Solid Seaworthy Wood Box Package with Steel Belt

Save space as much as possible for container loading