Immersion Gold Flexible Printed Circuit Board Assembly FR4 Stiffener PCB Test Systems

Brand Name:China chao sheng

Certification:ISO/UL/RoHS/TS

Model Number:CSFPC1002

Minimum Order Quantity:1PCS

Delivery Time:15-20 working days

Payment Terms:T/T, Western Union

Contact Now

Add to Cart

Active Member

Location:

Hong kong Hong kong China

Address:

Huishang Building, 19-128 Nathan Road, Yau Tsim Sha Tsui, Yau Tsim, Hong Kong

Supplier`s last login times:

within 48 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

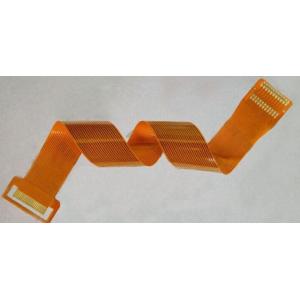

8 Layer Immersion Gold Flexible Printed Circuit Board Assembly FR4 Stiffener PCB test systems Other PCB & PCBA

Printed circuit board (pcb) and PCBA products

Communication terminal, communication station, electronic

communication, optical fiber, optical module, communication

equipment, communication instrument, computer, household appliance,

testing equipment, testing instrument, instrument, SD card, SG

card, mobile phone, computer, various antennas, cars, music

Equipment, playback equipment, banking equipment, medical

instruments, medical equipment, medical equipment, aerospace,

aviation, military, LED, OLED, OLCD power control power supply,

industrial power supply, communication power supply, automotive

power supply, office equipment, digital

products,computers,etc.Applications;

Flexible circuit board (FPC) and FPCA product areas

CD, hard disk, printer, fax machine, scanner, sensor, mobile phone,

connector, module, walkie-talkie antenna card, high-end camera,

digital camera, laser head, CD, medical, instrumentation, drive,

automotive instrumentation, medical instrument, Medical equipment,

banking equipment, industrial instruments, LED light bars,

military, aviation, aerospace, defense and other high-tech

products, of which more than 70% of the products are exported to

Europe, America, Europe, Central Europe, Western Europe, Southeast

Asia, Asia-Pacific and other countries and area.

Detailed Product Description

Immersion Gold Flexible Printed Circuit Board Assembly FR4 Stiffener PCB Test Systems

Inquiry Cart

0