Plastic Tyre Blow Molding Machinery , Automatic Blow Moulding Machine MP70D-1

Brand Name:MEPER

Certification:CE/ISO9001:2008

Model Number:MP70D-1

Minimum Order Quantity:1 set

Delivery Time:25-55 work days

Payment Terms:L/C, T/T

Contact Now

Add to Cart

Verified Supplier

Location:

Ningbo Zhejiang China

Address:

Zhutian, Xiaogang, Beilun, Ningbo, China

Supplier`s last login times:

within 37 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

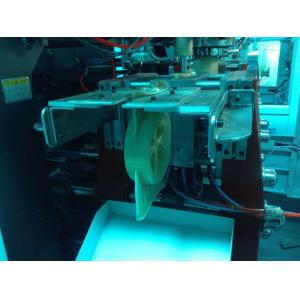

Plastic Tyre blow molding machinery for children's motor bike blow moulding machine MP70D-1 with servo system

Compare with injection,use Blow molding to produce tyre is more efficent,no need off-line work(assembeling,welding)

thickness can be adjustable,more flexiable

popular use for baby toys

Suggestion machine model MP70D-1

single station or double station optional

| MP70D Double station blow molder with horizontal linear mould shuttle | ||||

| Length: | 3600mm | |||

| Width: | 2200mm | |||

| Height | 2360mm | |||

| Key Data | MP70D | |||

| mm | ||||

| Linear mould stroke | A | 450 | ||

| Mould Width | B | 430 | ||

| Mould Length | C | 350 | ||

| Mould Thickness | D | 190 | ||

| Opening Stroke | E | 290 | ||

| Platen daylight | D+E | 480 | ||

| Clamping Force | 75kN | |||

| Dry Cycle | 7 sec. | |||

| Centre Distance | 2x2 fold | 160 | ||

| 2x3 fold | 120 | |||

| 2x4 fold | 100 | |||

| 2x6 fold | 60 | |||

| Extruder | φ70 | φ75 | φ80 | |

| Screw Speed | r/min | 0~65 | 0~65 | 0~65 |

| Screw Diameter | mm | 70 | 75 | 80 |

| Screw L/D Ratio | L/D | 24 | 24 | 24 |

| Energy Requirements | ||||

| Extruder Inverter Power | kW | 18.5 | 22 | 30 |

| Extruder Moter Power | kW | 18.5 | 22 | 30 |

| Srew Heating Power | kW | 12.7 | 14.4 | 15.85 |

| Fan Power | kW | 0.14X2 | 0.14X2 | 0.14X2 |

| Oil pump Motor Power | kW | 9.5 | 9.5 | 9.5 |

| Total Power of Machine | kW | 49.14 | 54.34 | 63.79 |

| Air Requirement approx | m3/min | 1.2 | 1.2 | 1.2 |

| Air Working Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Cooling Requirements | ||||

| Consumption Cooling Water | L/min | 40 | 40 | 40 |

Standard Features:

Auto Lubrication

Water Cooled Modular Blow Pin

Hot Wire Cutting

Positioning Hole For Quick Mold Change

Adjustable Die head

Linear Transducer

FRL(Filter Regulator Lubricator) for Pneumatic

Proportional Hydraulic System fro better control

Swing and Adjustable Extrusion Platform

| OPTIONAL FUNCTION |

| COLD CUTTER |

| DEFLESHING SYSTEM(MACHINE SYSTEM+STEEL BACK PLATEN AND PNEUATIC CYLINDER) |

| HYDRAULIC DEFLESHING SYSTEM |

| BOTTLE ROTATION TOP CUT OFFLINE |

| BLADE NECK ROTATION CUTTING ONLINE INSTALLED/OFF LINE SEPARATE |

| HYDRAULIC FILTER |

| MECHANICAL FILTER |

| LEAK TEST MC ON/OFF LINE |

| ROBOT TAKE OUT |

| IML(IN MOULD LABELING SYSTEM) |

| 2 YEAR SPARE PARTS WARRANTY |

| SCRAP MATERIAL CONVENYOR |

| BOTTLE CONVENYOR AROUND THE MACHINE OR CUSTOM DESIGN |

| POST COOLING SYSTEM |

| SIDE WATER REGUAR 12IN-12OUT WITH FLOW CONTROL |

| PARISON CONTROL SYSTEM MOOG 100PTS |

| SPECIAL SCREW AND BARREL FOR SPECIAL MATERIAL |

| SPECIAL PROGRA FOR SPECIAL PRODUCTS AND MOULD DESIGN |

LOADING DEVICE,MASTER BATH MIXING DEVICE |

Plastic Tyre Blow Molding Machinery , Automatic Blow Moulding Machine MP70D-1

Inquiry Cart

0