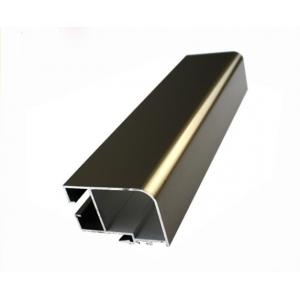

Sliding Glass Window Aluminium Alloy Profile , Stock Aluminum Extrusion Profiles

Add to Cart

Sliding glass window hardware,aluminum sliding parts Profiles

Specifiaction:

| Description | Sliding glass window hardware,aluminum sliding parts |

| Material Thickness(t) | t=1.0 / 1.2 / 1.4 |

| Material | Aluminum Alloy 6063, 6061 |

| Annealing Treatment | T5,T6 |

| Color | Green, Grey, Black, White, (RAL series)etc. |

| Surface Treatment | Mill finish, anodized, powder coated, electrophoresis, sand balsting etc.and depend on customer’s demand. |

| Shape | Square, Round, Flat, Oval, and according to customer's drawing. |

| Length | Normal length=6m or in customer's order |

| Usage | Building, Production Line, Decoration, Industrial, Transportation, Door and window, etc. |

| Package | 1. Pearl cotton foam for each profile; 2. Wrap with shrink film exterior; 3. Packed according to customer request. |

| Advantages/Features | Providing colorful products with various mechanical performances to adapt all kinds of architectural styles |

Chemical composition

| Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

| 6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

| 6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 |

Equipment

| Production lines | 22 |

| Anodizing and electrophoresis | 4 |

| Powder Coating | 2 |

| Wood Grain | 4 |

| Painting | 1 |

| Polishing | 1 |

| Brushing | 1 |

| Supply ability | 6000Tons per month |

Certificate

1: Guangdong famous brand

2: The ISO9001 quality management system certification

3: ISO14001 environmental management system certification

4: OHSMS18001 occupational health and safety management system certification,etc.

aluminum alloy defect repair

In the process of production, aluminum alloy is prone to shrinkage cavity, hole, porosity and slag. How to repair the defects of aluminum alloy castings? If it is repaired by electric welding, argon welding and other equipment, it is easy to produce thermal deformation and other side effects due to the large heat release, which can not meet the welding requirement. Cold soldering repair machine is used to repair casting defects by using the instantaneous discharge of high frequency electric spark and the principle of non - thermal surfacing. Because the cold welding thermal influence region is small, it will not cause the base material annealing deformation, no crack, no hard point and hardening phenomenon. Moreover, the welding strength is high, and the resolidification of the material and the substrate is melted at the same time. It can be used for grinding, milling, file and other processing, and the density will not fall off. Cold welding repair machine is an ideal method for repairing small defects such as air hole and sand hole.

aerospace

It mainly needs the integral band of reinforcement, girder, comb shape, hollow girder profile and applied to aerospace. Cable bridge, torpedoes, gas pipelines, shrapnel shell work aluminum aluminum pipe, irrigation pipe, seawater corrosion, high pressure, cooling tower shell, the pump body profile blades profiles, aluminum alloy, aluminum alloy bridge, wind power and high precision profile stands chairs, shower room profiles, medical equipment, textile equipment, woodworking equipment, electric motor casing, Marine stairs, metal roofing system, solar stent, pv silicon plate frame, LED series, chassis shell series hard disk, street lamp, lamp act the role ofing aluminum tubes, aluminum, sun, decorate class, central air conditioning, refrigeration equipment, industrial elevator, the elevator at the end, power tools, electronic instruments, household electrical appliances such as (computers, televisions, air conditioners, washing machines), industrial automation equipment, assembly equipment APAS, industrial aluminum assembly system can meet the requirements of a variety of tasks workbench, frame, machine cover, mechanical protection device, workstations, assembly station and checkpoints, conveyor, carts, clapboard, protective wall, shield, work space, special support, plant equipment, display systems, display cabinets, stands