Electrostatic Spray Epoxy Polyester Powder Coating For Radiator / Heat Sink

Add to Cart

electrostatic thermosetting spray epoxy polyester powder coating

1. Our Powder Coating Advantage:

(1) Spray ratio is 90%;

(2) 1KG of powder coating can spray 8-10 square meter;

(3) Powder Coating adhesive force is stronger 8-10 years;

(4) Powder Coating is not easy to fade in 5-8 years;

2. Charactcristic: Powder

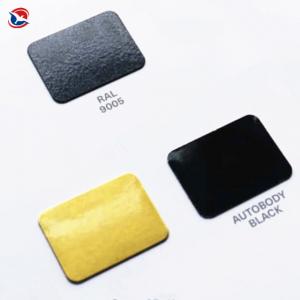

| Available Powder Types | Available Colors |

| 1. Epoxy powder coating | 1. RAL Colors |

| 2. Polyester Powder Coating | 2.Pantone Colors |

| 3.Epoxy-Polyester Powder Coating( Hybrid) | 3.Customer color matching |

| 4.Polyurethane Powder Coating | Available finish |

| 5.Heat transfer printing powder coating | 1. Smooth |

| Available gloss level | 2. Rough( Sand texture ) |

| 1. High gloss( Above 80%) | 3.Wrinkle( fine texture ) |

| 2. Flat gloss (50%-80%) | 4.Antique( hammer tone) |

| 3. Semi gloss(5%-50%) | 5.Metallic |

| 4. Matt ( below 5%) | 6.Other special effect ( artistic) |

3.usage

| Application Area | |

| 1. Household Applications | 7. Used for Security Door; |

| 2. Car Coating | 8. Radiator & Heat Sink; |

| 3. Used for Valve | 9. Corrosion Prevention of Pipes; |

| 4. Track Traffic | 10. Communications Equipments; |

| 5. Aerospare field | 11. Hardware & Brightwork; |

| 6. Fitness Equipment | 12. Zincing & Aluminium; |

| Bad symtoms | Possible Cause | Solution |

1.With low power, powder coating is not easy to coated; | 1. High voltage power supply shortage; | 1.Check the circuit |

| 2.Grouding is bad; | 2.Remove clutter grouding line | |

3.Compressed air volume is too big, the powder to blow fell &blows away; | 3.Spray appropriate isolation, reduct air convection; | |

| 4.Powder particle size is too thin; | 4.Add new powder coating, reduce the recovery powder consumption. | |

| 5.The air temperature is too high; | 5.Powder particles with air water branch of low power, control temperature of spray area; | |

2. Charge repulsion powder repboud from the working surface; | 1.The voltage is too high; | 1. Lower voltage and air volume; |

2.Spray gun from the work location is too close; | 2. Extend the spray gun and artifacts; | |

| 3. Grouding is bad; | 3.Remove clutter grouding line; | |

4.Powder particle size is too thin, not esay to attach to the workpiece surface; | 4.Add new powder coating, reduce the recovery powder consumption; | |

3. Corner not easy spraying penetration is bad; | 1. The powder amount is too small; | 1. Lower voltage and air volume, increasing the amount of powder; |

| 2. Grouding is bad; | 2. Adjust the spray gun position; | |

| 3. The voltage is too high; | 3. Choose small backboard, proper nozzle; | |

| 4. Spray gun position is not good; | 4.If the corner is more and deeper, then consider friction gun equipment; | |

| 5. Powder spraying range is too wide; | ||

| 4.Powder spraying uneven | 1. Air pressure is insufficient; | 1. Cleaning pipeline, spray gun and flowmeter; |

| 2.Line fault block; | 2.Check the air supply, Exclude water vapor in powder agglomeration; | |

| 3.Block in the spray gun; | 3.If powder agglomeration, to screen or change new powder coating; |