2000 M2 Agricultral Apple Cold Storage with 1500 M2 Processing Area of Fruits And Vegetables

Brand Name:ECOOL

Certification:ISO9001;CCC

Model Number:EHT23

Minimum Order Quantity:1 set

Delivery Time:3-6 months

Place of Origin:CHINA

Contact Now

Add to Cart

Active Member

Location:

Shanghai Shanghai China

Address:

588 South Qilianshan Road, Putuo District, Shanghai City, China

Supplier`s last login times:

within 24 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

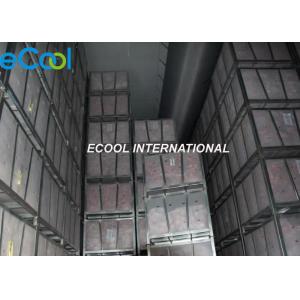

2000 M2 Agricultral Apple Cold Storage with 1500 M2 Processing Area of Fruits And Vegetables

Quick details:

- Overall construction site area: around 5000 square meter including parking area Cold storage building size: 68M *63M * 10M

- Cold storage cost (including steel structure, insulation, machine control and lights; exclude civil work such as foundation, finished concrete floor, fire-fighting etc.)

- Function: fruits and vegetables processing area 1420 M2, storage area 1980M2

- Designed temperature: evaporating temperature -7C; Condensing temperature +35C

Cold room specification:

| Function | cold store1 | cold store 2 |

| Quantity | 6 | 2 |

| Size per room | 10.5m*20M*7.5m | 12m*30m*6.5m |

| Capacity per room | 280 ton ~370tons | 420tons~560tons |

| Temperature | +/-2C | +/-2C |

Refrigeration system:

Refrigerant: Freon R22

Compressor brand: BITZER Screw type compressors

Control: PLC touch screen

Condenser: evaporative condenser one set

Evaporator: air coolers, one set/room; water defrosting

Compatitive Advantages

- Life-long free online technical suport service

- Many years of exporting and oversea project experience

- Fast construction

- 20+ years of field experts, 15+ years of engineer

- We can provide custom Fruits and Vegetables Cold Room Warehouse

Word famous brand components asure the quality e.g. BITZER compressor,DANFOSS valves etc.

- Intelligent remote-control model is available, for your convivence of remote control and getting remote technical support

- Refrigeration machine is high reliability, good performance and low noise,save energy up to 30%

Steps of customized cold storage

| Step | Contents | Details |

| 1 | Client describe the requests and using methods | 1. Client provides some basic requirements; |

| 2. Client provides relative information: | ||

| 1) construction address, environment, weather, geology conditions, electricity supply; | ||

| 2) storage purpose and functions; | ||

| Other design requirements | ||

| 2 | We offer sketch design and pric | 1. Communication on details, discussion and modification until reach an agreement; |

| 2. sketch design; | ||

| 3. price offer on all systems | ||

| 3 | Contract and formal design | 1. Sigh the former design contract (if any); |

| 2. Site survey and measurement (if necessary); | ||

| 3. Formal design and delivery; | ||

| 4. Details of solution and price. | ||

| 5. Client prepare the construction site and foundation. | ||

| 4 | Equipment and material export | 1. Sign the contract of equipment and materials; |

| 2. production and export preparation | ||

| 3. Client prepare the on-site electricity and water | ||

| 5 | Installation | 1. working procedure confirm and team organization; |

| 2. Construction teams go to install. | ||

| 6 | Check and acceptance | 1. Our technicians trial run the cold storage on-site; |

| 2. Client check and make acceptance. | ||

| 7 | Operation instruction and warranty | 1. training clients’ cold storage operators; |

| 2. provide technical support within the lifetime of cold storage. |

2000 M2 Agricultral Apple Cold Storage with 1500 M2 Processing Area of Fruits And Vegetables

Inquiry Cart

0