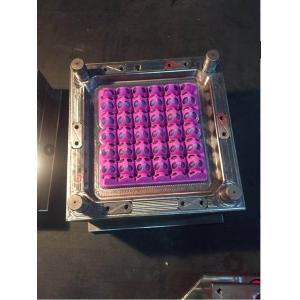

Custom Energy Saving Injection Molding Machine For Plastic Egg Tray Mould

Add to Cart

Plastic Mold (Mould) production process:

1. 3D drawing/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, product color, payment, moulds lifetime, delivery, etc.

3. Purchasing Order : After the customer confirming the mould design and quotation.

4. Making mold(moulds): Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start producion.

5. Production schedule: Every week we will feedback to the customer about the mold progress(picture).

6. Sample shoot: We provide the moulds test samples for confirmation(about 10-15 piece), we will start mass production when get your signature samples.

Parts Production Details -

| Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

| Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| MOQ | 1PCS |

| Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

| Shipping | By sea or by air as customer requirement |

| Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

| Typical Used For | Housings, containers, caps, fittings,including as below Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, |

| Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government,

construction, and fasteners. |

Our capability

| Manufacturing Capabilities | Machines: 3-axis Machining centers; CNC turning centers; Stamping machines; Tapping machines; Cutting machines; Polishing machines; sandblasting machines; |

| Materials | Aluminum; Brass; Bronze; Copper; Stainless Steel; Steel / Steel Alloys; Nylon; POM; Acrylic; Derlin; |

| Secondary Operations | Anodizing; Black Oxide; Electroplating; Heat Treating; Brushing; Grinding / Polishing; Painting / Powder Coating; |

| Additional Services | CAD/CAM Support; Design Assistance; Just-in-Time Delivery; Prototype Services; Low Volume Production; High Volume Production; Reverse Engineering; Assembly Services; |

| Length | custom size |

| Diameter | custom size |

| Drawing Software: | Solid work, Pro/E, AutoCAD CAM |

Inspection | Products are RoHS compliant; Test Equipment: CMM; 2.5D projector; Micrometer; Height gauge; The dimensions of first parts, middle parts and final parts must be recorded |