Add to Cart

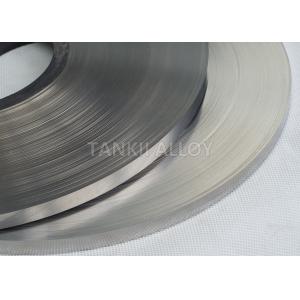

1Cr13Al4 FeCrAl alloy Bright Flat Strip/ Wide Strip for Resistors Use

Fecral Alloys and Nickel-chromium alloys have been chosen to be the resistive material for embedded resistor because nickel-chromium alloys possess high electrical resistivity that is widely used for thin film resistors. The sheet resistance of nickel-chrome alloy film containing 20% chromium can be as high as 2-3 kilo ohms and still maintain good stability. The temperature coefficient 1 of resistance (TCR) for bulk nickel-chrome alloy is about 110 ppm/°C. By alloying a small amount of silicon and aluminum with nickel-chromium, the temperature stability is further improved.

| Brand name | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Main chemical composition% | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| RE | opportune amount | opportune amount | opportune amount | opportune amount | opportune amount | opportune amount | opportune amount | |

| Fe | Rest | Rest | Rest | Rest | Rest | Rest | Rest | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Max.continuous service temp.of element (ºC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resistivity μΩ.m,20ºC | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Density (g/cm3 ) | 7.4 | 7.10 | 7.16 | 7.25 | 7.35 | 7.10 | 7.10 | |

| Thermal conductivity KJ/m.h.ºC | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| Coefficient of lines expansion α×10-6/ºC | 15.4 | 16.0 | 14.7 | 15.0 | 13.5 | 16.0 | 16.0 | |

| Melting pointºC | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile strength Mpa | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Elongation at rupture % | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Variation of area % | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Repeat bending frequency(F/R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Hardness(H.B.) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Micrographic structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic properties | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | Magnetic | |

Application:

Resistors embedded in a printed wiring board will be an enabler for miniaturizing packages with higher reliability and improved electrical performance. Integrating the resistor functionality into the laminate substrate frees up the PWB surface area consumed by discrete components, enabling increased device functionality by the placement of more active components. Nickel-chromium alloys possess high electrical resistivity, which make them practical for use in a variety of applications. Nickel and chromium are alloyed with silicon and aluminum to improve temperature stability and lower the thermal coefficient of resistance. A thin film resistive layer based on nickel-chromium alloys has been deposited continuously onto rolls of copper foil to create a material for embedded resistor applications. The thin film resistive layer sandwiched between copper and laminate can be selectively etched to form discrete resistors. The chemicals for etching are common in PWB production processes. By controlling the thickness of the alloys, sheet resistance values from 25 to 250 ohm/sq. are obtained. This paper will compare two nickel-chromium materials in their etching methodologies, uniformity, power handling, thermal performance, adhesion and etching resolution.