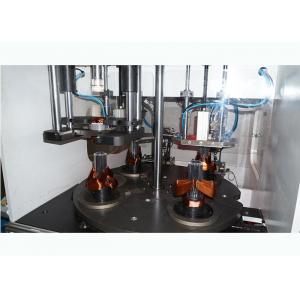

ElectricInduction Motor Winding Machine inserting Drift Forming System

Add to Cart

ElectricInduction Motor Winding Machine inserting Drift Forming System

1. Machines offter automatic linear stator handling and

simultaneous forming of both and turns

2. Quick, no hand tools, complete lamination tooling changeover .

3. All electric and pneumatic operation with no hydralics (

optional)

4. Automatic load / unload of stator ( optional )

Stator handling arms with or without cuff supports .

5. it is electircally and pneumatically controlled with no

hydraulics . this system features automatic winding and stator

handling , downloaded specification and simple quick lamination

tooling changeover .

1. Our Service:

| Product Name | Automatic Winding and Inserting Machine | Application | Electric motor stator production |

| Status | New | Paint | On request |

| Warranty time | One year after machine(s) arrive in customer’s plant | Service | Overseas service center available |

2. Basic Parameters

1. Basic machine complete with controls, less tooling.

2. Heavy duty construction.

3. All electric and pneumatic - no hydraulics.

4. Machine enamel paint on request.

5. Allen Bradley Programmable Controller.

6. Compact design on wheels for ease of relocation and

operator convenience.

7. Maximum stack height up to 4 inches, 102mm, with rapid

adjust feature.

8. Four-station turntable.

9. Smooth precise sinusoidal turntable index.

10. Specification storage for use with the Windows compatible

computer.

3. SOFTWARE FEATURES:

a) Specification storage of over 1,000 winding patterns.

b) One (1) minute specification change.

c) Upload/download to disk capability.

d) Machine diagnostics utilizing visual basic software and full

access to servo software.

e) Machine functions independent of computer for reliability.

f) Easy menu access to all machine winding parameters.

g) Maintenance recording and access password protected.

h) Pre-programmed maintenance schedules with operator prompting.

4. About Us

Take full advantage of experienced engineers , skillful professional , perfect equipment , strict manufacturing process control and wide coverage service net-work , we are dedicated to provide our customers with the optimized solution to electric motor manufacturing , so far , except the big market share in China , we export our machines to the worldwide countries such as USA Italy , Australia , India , Brazil , Mexico ,Turkey , Tailand , Vietnam Iran etc,and our machines share the great the reputation among customers for its durable , reliable perormance , reasonable price and good after sales.