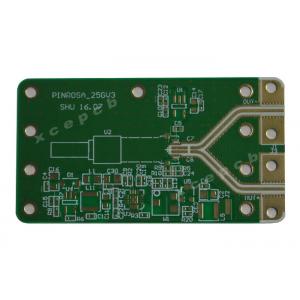

Electronic Circuit Rogers Material PCB FM Equipment Automotive Pressure Sensors Board

Add to Cart

Electronic Circuit High Frequency Rogers PCB FM Equipment Automotive Pressure Sensors Board

Quick detail:

| Origin:China | Special: High frequency pcb |

| Layer:4 | Thickness:0.634mm |

| Surface: ENIG | Hole:0.8 |

Specification:

High frequency pcb high-performance insulating material for microwave, radio frequency (RF) and high-speed digital signal processing (DSP) market with PTFE/type woven glass fiber fabric sheet.This material can be applied to LNAs LNBs, PCS/PCN antenna system, global positioning system (GPS) and UMTS antenna system,And the power amplifier, passive components, collision avoidance radar system, aviation help guide remote control technology and system of the phased array radar.

High frequency materials are UL 94V-0 rated for active devices and high power RF designs.

Typical Applications

- Cellular Base Station Antennas and Power Amplifiers

- Microwave point to point (P2P) links

- Automotive Radar and Sensors

- low dielectric loss

- RF Identification (RFID) Tags

- The stability of the dielectric constant

- An extremely low water imbibition

- LNB’s for Direct Broadcast Satellites

Depending on various parameters, HF signals are reflected on circuit board, meaning that theimpedance (dynamic resistance) varies with respect to the sending component. To prevent such capacitive effects, all parameters must be exactly specified, and implemented with the highest level of process control.

Critical for the impedances in high frequency circuit boards are principally the conductor trace geometry, the layer buildup, and the dielectric constant (er) of the materials used.

Characteristics of the material are excellent temperature stability having a dielectric constant of the dielectric constant of the thermal expansion coefficient of copper is very consistent, to improve inadequate PTFE substrate. This product is ideal for dramatic changes in the ambient temperature of the application (IAF), due to its low dielectric loss and high reliability through metalized holes, it can be used at higher frequencies and multilayer structures.

Parameter:

| o | Item | Data |

| 1 | Layer: | 1 to 24 layers |

| 2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| 3 | Board thickness: | 0.20mm to 3.4mm |

| 4 | Copper thickness: | 0.5 OZ to 4 OZ |

| 5 | Copper thickness in hole: | >25.0 um (>1mil) |

| 6 | Max. Board Size: | (580mm×1200mm) |

| 7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

| 8 | Min. Line Width: | 3mil (0.075mm) |

| 9 | Min. Line Spacing: | 3mil (0.075mm) |

| 10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| 11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| 12 | Shape tolerance: | ±0.13 |

| 13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| 14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| 15 | Certificate: | UL,SGS,ISO 9001:2008 |

| 16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

| 17 | Profiling: | Punching, Routing, V-CUT, Beveling |

Features

• High Thermal Performance

Tg: 180°C (DSC)

Td: 340°C (TGA @ 5% wt loss)

Low CTE for reliability

• T260: 60 minutes

• T288: 30 minutes

• RoHS Compliant

• UV Blocking and AOI Fluorescence

High throughput and accuracy during PCB

fabrication and assembly

• Superior Processing

Closest to conventional FR-4 processing

• Core Material Standard Availability

Thickness: 0.002″ (0.05 mm) to 0.125″

(3.2 mm)

Available in full size sheet or panel form

• Prepreg Standard Availability

Roll or panel form

Tooling of prepreg panels available

• Copper Foil Type Availability

Standard HTE Grade 3

RTF (Reverse Treat Foil)

• Copper Weights

½, 1 and 2 oz (18, 35 and 70 μm) available

Heavier copper available upon request

Thinner copper foil available upon request

• Glass Fabric Availability

Standard E-glass

Square weave glass fabric available

Spread glass fabric available

• Industry Approvals

IPC-4101C /21 /24 /26 /97 /98 /99 /101 /126

UL - File Number E41625 as PCL-FR-370HR

Qualified to UL's MCIL Program

Rogers material in stock:

| Brand | Model | Thickness(mm) | DK(ER) |

| F4B | F4B | 0.38 | 2.2 |

| F4B | 0.55 | 2.23 | |

| F4B | 0.225,0.3,0.5,08,1,1.2,1.5,2,2.5,3.0 | 2.65 | |

| F4Bk | 0.8,1.5 | 2.65 | |

| F4B | 0.8 | 3.5 | |

| FE=F4BM | 1 | 2.2 | |

| Rogers | RO4003 | 0.254 0.508,0.813,1.524 | 3.38 |

| RO4350 | 0.254 0.508,0.762,1.524 | 3.5 | |

| RO5880 | 0.254.0.508.0.762 | 2.2 | |

| RO3003 | 0.127,0.508,0.762,1.524 | 3 | |

| RO3010 | 0.635 | 10.2 | |

| RO3206 | 0.635MM | 10.2 | |

| R03035 | 0.508MM | 3.5 | |

| RO6010 | 0.635MM, 1,27MM | 10.2 |