Complete Quarry Stone Crushing Machine Production Line Capacity 200 T / H

Add to Cart

Complete Quarry Stone Crushing Production Line , Stone Crushing Machine

Introduction of Stone Crushing Production Line

The Stone Crushing Production Line consists of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, electric control, etc. We design different production lines ranging 50 t/h to 500 t/h by combining different models of equipment which can match cone crusher, deduster, etc.

We Here Recommend Three Proposals:

Proposal 1: vibrating feeder +primary jaw crusher +impact crusher +vibrating screen +belt conveying system +control system

Proposal 2: vibrating feeder +primary jaw crusher +fineness jaw crusher +impact crusher(optional)+vibrating screen +belt conveying system +control system

Proposal 3: vibrating feeder +primary jaw crusher +Compound cone crusher +impact crusher(optional)+vibrating screen +belt conveying system +control system

In the above proposals, the main difference is the secondary crusher: using impact crusher (hammer crushing principle), or using fineness jaw crusher(plate pressing principle), or Compound cone crusher(plate pressing principle).

If the local market has not request of the stone shape, users prefer to use fineness jaw crusher, or Compound cone crusher as the secondary crusher. Because for high hardness stones, the quick wear parts cost of fineness crusher/cone crusher is lower than that of impact crusher.

For jaw crusher and compound cone crusher, the working principle is plate pressing, so the percentage of stones with flaky shape, internal cracks is high.

For impact crusher, it has the functions of crushing and shaping, can make very good cubic shape; the stone materials are mainly used for highway, water conservancy, airport, civil construction, etc. The market prices of stones made by impact crusher is higher than that by fineness jaw crusher or compound cone crusher; the quick wear parts cost of impact crusher is also high for high hardness stones.

If the market has request for the stone shape, and the users want to reduce the quick wear parts cost. Here we recommend firstly use primary jaw crusher + fineness jaw crusher/compound cone crusher as the primary and secondary crushers, take the impact crusher as the tertiary crusher to shaping the stones. This proposal has been adopted by many users, and proved to be workable.

Technical Data:

Processing (t/h) | Major equipment type, size, number | |||||

| Feeding equipment | Crushing equipment | Crushing equipment | Classification and screening equipment | Belt Conveyor(m) | Installed power(kw) | |

| 30 | GZD8030 | PE400×600 | PF1008 | 2YK1235 | 60-90 | 120 |

| 50 | GZD8530 | PE400×600 | PF1008 | 3YK1235 | 100-130 | 140 |

| 80 | GZD9636 | PE500×750 | PF1010 | 3YK1545 | 130-160 | 200 |

| 100 | GZD9638 | PE600×900 | PF1210 | 3YK1545 | 140-180 | 280 |

| 150 | GZD1142 | PE750×1060 | PF1214 | 3YK1854 | 200-240 | 300 |

| 200 | GZD1142 | PE750×1060 | PF1315 | 3YK1860 | 200 | 350 |

| 250 | GZD1149 | PE750×1060 | PF1214/2 | 3YK2160 | 200 | 400 |

| 300 | GZD1249 | PE900×1200 | PF1315/2 | 3YK2160 | 250 | 450 |

| 350 | GZD1349 | PE1000×1200 | PF1315/2 | 3YK2460 | 250 | 500 |

| 450 | GZD1349 | PE1000×1200 | PF1315/2 PF1214 | 3YK2160/2 | 350 | 600 |

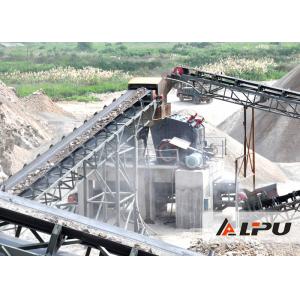

The Working Site of Stone Crushing Plant