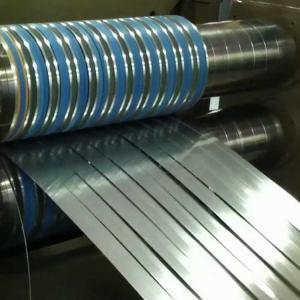

AMS 5513 2B Stainless Steel Precision Strip Roll 4mm Thickness

Add to Cart

304 Stainless Strip, Coil, Foil & Wire, AMS 5513, AMS 5910 (1/4H), AMS 5911 (1/2H), AMS 5912 (3/4H), AMS 5913 (FH), AMS 5501 (1/4H), ASTM A666

AMS 5513 304 Stainless steel strips coil Annealed No.1 2B Annealed For general industry overview

Stainless steel 304 is an austenitic grade of stainless steel that contains high nickel content, typically somewhere between 8 and 10.5 percent by weight and a high amount of chromium that comprises approximately 18 to 20 percent by weight. The lower carbon content of grade 304 stainless steel minimizes chromium carbide precipitation from welding and the alloy’s susceptibility to intergranular corrosion.

304 stainless strip can achieve high hardness and strength through cold working. In the annealed condition, type 304 stainless steel strip is very ductile and can be cold worked easily through operations like roll forming, deep drawing, bending, and other common manufacturing processes. Stainless steel 304 strip is often specified for these characteristics given its high ductility, excellent drawing, forming, and spinning properties. The alloy work hardens rapidly, but in-process annealing is sometimes necessary to restore desirable ductility characteristics and lower hardness.

The 304 grade of stainless steel is known to have better corrosion resistance than Type 302. In regards to magnetic properties, 304 stainless steel is essentially non-magnetic, and only becomes slightly magnetic when cold worked. It has resistance to moderately aggressive organic acids is a result of the 9 to 11% nickel that the 304 alloys contain. Type 304 stainless steel strip also has resistance to corrosion in oxidizing environments is a result of the 18 to 19% chromium that the 304 alloys contain.

The alloy also exhibits excellent toughness, even down to cryogenic temperatures. On the other side of the spectrum, in terms of resistance to oxidation, this stainless steel alloy can be exposed to temperatures of about 1650F continuously appreciable scaling.

Type 304 can be easily welded using common fusion and resistance methods, like most other austenitic grades.

PRODUCT FORMS:

Sheet, plate , Strip, pipe ,tube ,bar ,profiles

Equivalent Materials

| AISI 304 equivalents | ||

| ASTM A887 Grade S30460 | EN X5CrNi18-10 | ASTM F594 Grade S30500 |

| ASTM A887 Grade S30461 | EN 1.4301 | ASTM F594 Grade Alloy Group 1 |

| ASTM A887 Grade S30462 | ISO A2 | ASTM F738M Grade S30500 |

| ASTM A887 Grade S30463 | GOST 08Ch18N10 | ASTM F738M Grade Alloy Group A1 |

| ASTM A887 Grade S30464 | GB 0Cr18Ni9 | ASTM F836M Grade S30500 |

| ASTM A887 Grade S30465 | UNS S30400 | ASTM F836M Grade Alloy Group A1 |

| ASTM A887 Grade S30466 | ASTM A193 Grade B8P Class 1D | ASTM F837 Grade S30500 |

| ASTM A887 Grade S30467 | ASTM A193 Grade B8P Class 1 | ASTM F837 Grade Property Class A1 |

| DIN 1.4301 | ASTM A193 Grade B8P Class 2 | ASTM F879 Grade S30500 |

| DIN X 5 CrNi 18 9 | ASTM A193 Grade B8PA Class 1A | ASTM F880 Grade S30500 |

| DIN X5CrNi18-10 | ASTM A194 Grade 8P | DIN 1.4314 |

| AFNOR Z6CN18-09 | ASTM A194 Grade 8PA | AFNOR 9160/C 109 |

| AFNOR Z7CN18-09 | ASTM A240 Grade S30500 | AFNOR 9160C411 |

| BS 304S15 | ASTM A249 Grade TP305 | AFNOR Z 12 CN 18-10 |

| BS 304S31 | ASTM A276 Grade S30500 | AISI 305 |

| UNI X5CrNi1810 | ASTM A313 Grade S30500 | SAE 305 |

| SS 2332 | ASTM A314 Grade S30500 | EN FE-PA 11 |

| UNE F.3551 | ASTM A320 Grade B8P Class 1 | EN FE-PA 12 |

| SAE 304 | ASTM A320 Grade B8P Class 2 | EN 1.4314 |

| JIS SUS304 | ASTM A320 Grade B8PA Class 1A | DIN 1.4350 |

| JIS SUS304TBS | ASTM A368 Grade 305 | DIN X5CrNi18-9 |

| JIS SUS304TPD | ASTM A473 Grade 305 | AFNOR Z6CN18.09 |

| JIS SUS304TP | ASTM A478 Grade 305 | SS 2333 |

| JIS SUS304TPY | ASTM A492 Grade S30500 | EN 1.4350 |

| JIS SUS304TB | ASTM A493 Grade S30500 | |

| JIS SUS304TF | ASTM A511 Grade MT305 | |

| JIS SUS304TKA | ASTM A554 Grade MT305 | |

| JIS SUS304TKC | ASTM A580 Grade S30500 | |

| JIS SUSF304 | ASTM A959 Grade S30500 | |

| ASTM F593 Grade S30500 | ||

| ASTM F593 Grade Alloy Group 1 | ||

AMS 5513 304 Stainless steel strips coil Annealed No.1 2B Annealed For general industry Products Specification and Dimension Ranges

Hot Rolled Strip Available Size

Width: 16.0~609.6 mm

Thickness: 2.5~10.0 mm

Available Steel Grade:

Cold Rolled Strip Available Size

Width: 4.0~609.6 mm

Thickness: 0.1~3.0 mm

Surface Finish:

2B, 2D, BA, No.3, No.4, No.5, SB, HL, etc

| Surface finish | Characteristics and application |

| NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy compreh ensive uses. |

| NO.1 | The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling. |

| NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150#320 on the NO.4 finish and has continuous streaks,mainly used as buildingsornaments elevators,door of building,frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Condition :

ANNEALED CONDITION

Ultimate Tensile Strength: 95 KSI min (655 MPA min) Yield Strength (0.2% Offset): 38 KSI min (260 MPA min) Elongation: 40%min Hardness: B95 max

TEMPERED 1/16 HARD

Ultimate Tensile Strength: 95 KSI min (655 MPA min) Yield Strength (0.2% Offset): 45 KSI min (310 MPA min) Elongation: 40% min

Tempered 1/8 Hard Ultimate Tensile Strength: 100 KSI min (690 MPA min) Yield Strength (0.2% Offset): 55 KSI min (380 MPA min) Elongation: 45% min

TEMPERED 1/4 HARD

Ultimate Tensile Strength: 125 KSI min (860 MPA min) Yield Strength (0.2% Offset): 75 KSI min (515 MPA min) Elongation: 25% min

TEMPERED 1/2 HARD

Ultimate Tensile Strength: 150 KSI min (1035 MPA min) Yield Strength (0.2% Offset): 110 KSI min (760 MPA min) Elongation: 15% < 0.15" 18% > 0.15"

TEMPERED 3/4 HARD

Ultimate Tensile Strength: 175 KSI min (1205 MPA min) Yield Strength (0.2% Offset): 135 KSI min (930 MPA min) Elongation: 10% < 0.15" 12% > 0.15"

TEMPERED FULL HARD

Ultimate Tensile Strength: 185 KSI min (1275 MPA min) Yield Strength (0.2% Offset): 140 KSI min (965 MPA min) Elongation: 8% < 0.15" 9% > 0.15"

Available Steel Grade:

Stainless steel : Type 201, 202, 205, 301, 302, 302B, 303, 303Se, 304, 304L, 302HQ, 304N, 305, 308, 309, 309S, 310, 310S, 314, 316, 316L, 316F, 316N, 317, 317L, 317LMN, 321, 330, 347, 348, 384, 405, 409, 429, 430, 430F, 430FSe, 434, 436, 442, 446, 403, 410, 414, 416, 416Se, 420, 420F, 422, 431, 440A, 440B, 440C, 630 , 13-8 PH ,15-5 PH , 17-7 PH ,17-4 ph , 904L , A286 ,VG-10 , SAE 316 , SAE 316L , SAE 440 , SAE 420

Duplex stainless steel : 2205 , 2304 , 2507

Nickel alloy :

Titanium and titanium alloys

AMS 5513 304 Stainless steel strips coil Annealed No.1 2B Annealed For general industry Application

Typical Applications for 304 stainless steel strip:

- hypodermic needles

- flexible hoses

- clamps

- evaporators

- bellows

- airbag sensors

- tubing

- cooling coils

- hinges

- oil and gas filter screens

AMS 5513 304 Stainless steel strips coil Annealed No.1 2B Annealed For general industry Technical datasheet

| TYPE 304 STAINLESS STEEL STRIP Type 304, ASTMA-666, is similar to Type 302, but has a maximum carbon content of .08%. This material has an excellent combination of corrosion resistance and fabricability | |||||||||

| Chemical Composition (AMS 5513) | % | Thickness Tolerances < 6” (AMS 2242) | Tolerance (inch) +/- | ||||||

| Carbon | 0.08 max | over .050 - .062 incl | +/- .0030 | ||||||

| Manganese | 2.00 max | over .035 - .050 incl | +/- .0025 | ||||||

| Silicon | 1.00 max | over .029 - .035 incl | +/- .0020 | ||||||

| Phosphorus | .040 max | over .020 - .029 incl | +/- .0020 | ||||||

| Sulfur | .030 max | over .017 - .020 incl | +/- .0015 | ||||||

| Chromium | 18.00 -20.0 | over .013 - .017 incl | +/- .0015 | ||||||

| Nickel | 8.0 – 10.5 | over .011 - .013 incl | +/- .0015 | ||||||

| Molybdenum | 0.75 max | over .010 - .011 incl | +/- .0015 | ||||||

| Copper | 0.75 max | under .010 | +/- 10% | ||||||

| Mechanical Properties (AMS 5513) | |||||||||

| Condition | AMS Specification | Tensile Min PSI | Yield Min PSI | Elong % Min | Hardness | ||||

| Annealed | 5513 | 75,000 | 30,000 | 40 | RB 92 max | ||||

| ¼ Hard | 5910 | 125,000 | 75,000 | 10 / 12* | RC 25 min | ||||

| ½ Hard | 5911 | 150,000 | 110,000 | 6 / 7** | RC 32 min | ||||

| ¾ Hard | 5912 | 175,000 | 135,000 | 3 / 5** | RC 37 min | ||||

| Spring | 5913 | 185,000 | 140,000 | 3 / 5** | RC 41 min | ||||

| *Over .030 thickness ** Over .015 thickness | |||||||||

| Additional Information | |||||||||

| Width Tolerance | +/- .003 | ||||||||

| Camber Tolerance | Up to and including 1.500” wide | .500” in 8 feet | |||||||

| Over 1.500” wide | .250” in 8 feet | ||||||||

| Edges available | #3 Slit edge | ||||||||

| #5 Deburred edge | |||||||||

| #1 Round edge | |||||||||

ADDITIONAL PROPERTIES

FINISHES

# 1 - Hot rolled annealed and descaled. It is available in strip, foil and ribbon. It is used for applications where a smooth decorative finish is not required.

# 2D - Dull finish produced by cold rolling, annealing and descaling. Used for deep drawn parts and those parts that need to retain lubricants in the forming process.

# 2B - Smooth finish produced by cold rolling, annealing and descaling. A light cold rolling pass is added after anneal with polished rolls giving it a brighter finish than 2D. #BA- Bright annealed cold rolled and bright annealed #CBA- Course bright annealed cold rolled matte finish and bright anneal

#2 - Cold Rolled

# 2BA- Smooth finish produced by cold rolling and bright annealing. A light pass using highly polished rolls produces a glossy finish.

2BA finish may be used for lightly formed applications where a glossy finish is desired in the formed part. Polished - Various grit finish for specific polish finished requirements. * Special finishes are available for all alloys - Contact US for more information.

AMS 5513 304 Stainless steel strips coil Annealed No.1 2B Annealed For general industry Products display and Package Details

FAQ

Q: Would you provide samples For free?

A: Yes . with on stock specification We provide samples For Free . Freight charge collect