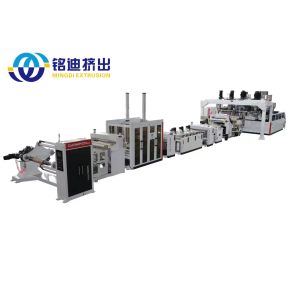

Product Details

Barrel Co-Rotating Twin Screw Extruder/Double Screw

Extruder/Compounding Extruder

MINGDI Barrel Co-Rotating twin screw extruder for Master batch

Compounding

- Masterbatch is a concentrated mixture of pigments and/or additives

encapsulated during a heat process into a carrier resin which is

then cooled and cut into a granular shape.

- MINGDI Co-rotating twin screw extruder will melt, mix, kneading the

dry blend of resin carrier and pigments and additives and pelletize

into perfece master batch pellets by water strand pelletizing.

- MINGDI Clamshell barrel Co-rotating twin screw extruder can be

opened for cleaning, checking, and maintenance. It is ideal for

color changing for Master batch compounding

Main features:

- Efficient TWIN screw design: Optimized screw structure and speed

design ensure efficient plasticization and uniform extrusion of

plastic materials during extrusion.

- Precise temperature control system: Equipped with advanced

temperature control system, it can precisely control the

temperature during the extrusion process to ensure the quality and

stability of the plastic sheet.

- Flexible adjustment: Extrusion speed, temperature and plate

thickness can be flexibly adjusted according to production needs to

meet diversified production needs.

- High-quality materials: The use of high-quality materials to ensure

the durability of the equipment and long-term stable operation.

- Easy operation and maintenance: user-friendly operation interface

and simple mechanical structure make the equipment easy to operate

and maintain.

Scope of application:

This PP/PS plastic sheet twin screw extruder is widely used in

packaging, construction, advertising, home and other industries, is

the ideal choice for the production of high-quality plastic sheets

and films.

This versatile twin screw extruder is primarily used in sectors

such as packaging, construction, advertising, and home goods. Its

ability to produce high-quality plastic sheets and films makes it

an ideal choice for manufacturers seeking to enhance their product

offerings. The extruder is particularly beneficial for

color-changing processes in masterbatch compounding, as the

clamshell barrel design allows for easy cleaning and maintenance.

This adaptability ensures that businesses can efficiently meet

evolving market demands while maintaining high standards of quality

and performance.

Company Profile

Zhejiang Mingdi Extrusion Machinery Co.,Ltd was established in 2011 and is located in Changxing, the beautiful

coast of Taihu Lake, with a construction area of over 20,000

square meters. The company is a leading enterprise specializing in

the production of various high-performance plastic sheet and plate

extrusion production lines. The company has a professional R&D

team and a complete after-sales management team, committed to

providing customers with high-quality and low-energy consumption

production lines. Currently, our products have been exported to

Russia, Turkey, Iran, Southeast Asia and other countries and

regions. With more than ten years of pioneering and innovation,

Mingdi has been highly praised by customers at home and abroad for

its highly specialized technical equipment and considerate

services.