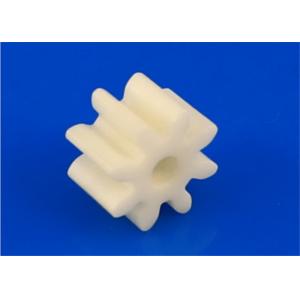

Precision Zirconia Ceramic Gear Ceramic impeller for High Pressure Cleaning Machine

Add to Cart

Precision Zirconia Ceramic Gear Ceramic impeller for High Pressure Cleaning Machine

Zirconia Ceramic Gear Product Name:Precision Zirconia Ceramic Gear Shafts

| Descriptions: | Zirconia ceramic are used in shaft , plunger, high-Pressure

cleaning machines. sealing structure,auto mobile Industrial, oil

drilling equipment, Insulation parts in electrical equipment ,

ceramic knife, ceramic hair clipper spare parts, with high density,

bending strength and breaking tenacity. We can produce zirconia ceramic parts according to your | ||

Zirconia ceramic gear ,Zirconia ceramics gear , Industrial ceramic gear are made of high purity and super-fine raw material with the application of the

most advanced technology in the world. It can be mainly used to grind and disperse

super-fine powder.

Mingrui Specilize in manufacturing as per your size.

Zirconia Ceramic Gear Feaures :

・[High strength/Abration resistance] Good property of ceramic such

as abration resistance and high strength extend the life span of

the parts.

・[Weight saving] If Compare the same volume,Ceramics are around 20%

lighter than steel.

・[Cost reduction] Reducing processes contribute to cost reduction.

・[Custom-made] We respond to your various requests.

1) High hardness, high strength, high wear and chemical corrosion

resistance, low expansion coefficient. |

Description of Ceramic gear

Ceramic gear can withstand high temperature and maintain high strength and

hardness. zirconia plates also have superb performances in

electrical insulation, high chemical resistance and low thermal

expansion. We have various sizes of semi finished shapes in stock

and are able to conduct custom manufacturing for all kinds of

alumina components.

Applications of ceramic gear :

• ceramic gear are hard enough to become armor for personnel or vehicles.

• The corrosion resistivity of alumina plates makes them a great

material for chemical industry.

• Used as a material for industrial furnaces due to its ability to

maintain its hardness at high temperatures.

• Used for making parts for CVD, ion implants, photolithography,

and semiconductor parts.

• In traditional industries, alumina ceramics are ideal for

products such as injector tubes, gas nozzles and insulators.

*This chart just demonstrates the typical properties of common alumina materials we use to produce our alumina parts. Please notice that the property for customized alumina parts could vary due to different process. Stanford Advanced Materials could provide alumina products produced under your specified instruction, or do the best to meet customers’ requirements.

2. Very small and very large size can be made

3. High temperature, good abrasive.

Refractory alumina ceramic substrate/ceramic plate is our main product.Misson can supply high quality alumina plates with competitive prices.

Very small and very large sized plates can be made.

Fine grinding can made tight tolerance.

High temperature and abrasive resistance is good

Quality assurance:

1. High heat resistance : Zirconia ceramic has excellent thermal

stability,which means that it is widely used in areas where

resistance to high temperatures is essential.

2. Good wear resistance : Zirconia ceramic is the material of

choice for wear parts.

3. High corrosion resistance : It is insoluble in water and only

slightly soluble in strong acid and alkaline solutions. Good

chemical stability of alumina leads to high corrosion resistance.

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical insulation properties together with high hardness and good wear resistance,but relatively low strength and fracture toughness.Alumina ceramics are generally white but may also be pink or ivory.The color is derived from either the sintering additives or impurities in the raw materials.

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great successes in particular requirements

which is based on cooperating with Tsinghua University and getting rich experience by our professional technical engineer teams . Our factory have an unique technical called mirror polishing which improve

our products more smooth , bright than other competitors.

FAQ :

1. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic parts .

2. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die casting , tape casting , injection molding, etc, injection molding and isostatic molding is the most commonly used.

3.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial ceramic parts.

4.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to the product complexity .

5.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but paypal and western union only for small -sum payment.