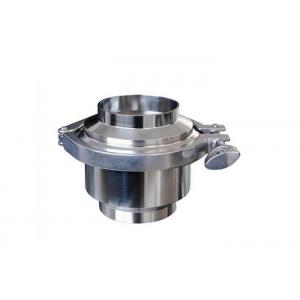

Tri Clamp Sanitary Ball Check Valve 4 Inch Operating Pressure To 150 Psi

Add to Cart

4 Inch Sanitary Ball Check Valve , Tri Clamp Check Valve Operating Pressure To 150 Psi

Sanitary Check Valve is the sanitary valves worked to prevent the flow from reversing. It is made in stainless steel AISI 316L or 304, with the adavantages of smooth surface, seamless, automatic emptying and easy to maintain etc. Sanitary check valve is also applied to steam and self-cleaning requirement, it is a good choice for the application of food,beverage,biopharmacy etc. With different connection ends, sanitary check valve from NYHAU assures you a safe, easy, fast pipeline.

- Available sizes 1/2" - 6"

- Suitable for C.I.P.

- Operating pressure to 150 psi

- Temperature from 30°F min. to 225°F max.

- Standard end connection-clamp type (butt weld &TI-Line upon request)

- Standard seals-FDA Viton (EPDM & other elastomers upon request)

- Internal finish-25 to 30ra average

- Material Test Reports provided upon request

- Eccentric Type available upon request

Material:

Stainless Steel 304,316L or en.1.4301, 1.4404 etc.

Application:

Food, Brewery, Beverage, Dairy, Pharmaceutical, Biopharma etc.

Sanitary check valve also known as one-way valve, its role is to prevent the pipeline water back in the media. Are different to many other types of valves,for check valves work automatically and most are not controlled by a person or any external control. Accordingly, most do not have any valve handle or stem. Thus there is an important concept in check valves, it is, the cracking pressure. Cracking pressure is the minimum upstream pressure at which the valve will operate. So the check valve is designed for and can therefore be specified for a specific cracking pressure.

| General Specifications of Sanitary Check Valve | ||

| Working Pressure | Working Pressure | 0~10 bar |

| Opening Pressure | 0.1~0.3bar | |

Working Temperature | Continuous Working Temperature | -10°C ~ +121°C(EPDM) |

| Sterilization Temperature | 150°C (Max 20min) | |

| Surface Finish | Internal Surface Finish | R0.8m |

| External Surface Finish | R1.6m | |

| Connections | Connection Standards | DIN, SMS, 3A, ISO |

| Connection Methods | Welding, Clamp, Threading | |

| Material | ||

| Metal Material | Product Wetted | 304 (1.4301) or 316L (1.4404) forged |

| Other Steel Parts | 304 (1.4301) | |

| EN 10204 3.1B certificate is available on request. | ||

| Seal Material | Standard | EPDM |

| Options | FPM, Silicone, NBR | |

| All seal materials comply with FDA 177.2600. | ||

Design:

- Forged valve body ensures non-porous, smooth surfaces and stable structure.

- Compact and simple structure makes sanitary check valve easy to clean and maintain without special tools.

- Sanitary weld check valve Male check valve and Sanitary Tri Clamp Check Valve are two splitted design, assembled by a clamp and sealed with a gasket.

- Sanitary union type check valve is basically consist of a valve body, a cover and a nuts in threaded union form.

- Ribbed construction of the stainless steel disc resists heavy pressure hammer, minimizes the resistance to flow and also serves as a guide to the valve plug.

- Eccentric design allows the check valve installing vertically or horizontally.

Strength:

- Material of stainless steel 316L and 1.4404 is from reputed mill to guarantee the chemical composition and mechanical propertis. Material certificate will be submitted follow to orders.

- Forged valve body and disc to control the leakage and visual.

- Superior facilities and good experiences for fabrication.

- In ability to improve and develop new design.

- Fast delivery is possible to meet your needs well in time.

- Low cost from bulk production will reduce your budget and improve your business.

- Small quantity available.

Quality & Inspection:

- PMI test to verify material grade

- Dimension controlling during fabricating and finished

- Visual and surface 100% examination before shipment

- Packed in carton box firstly, then in wooden case

- Third party inspection available.

Dimension of Sanitary Check Valve – 3A,SMS,ISO,IDF,DS

| SIZE | H | D | D1 | t | G(RD) |

1” 1 1/4” | 110 112 | 72 87 | 25.4 31.8 | 1.5 1.5 | 33.5*1/8 39.5*1/6 59.5*1/6 |

| 2” 2 1/2” | 119 141 | 100 115 | 50.8 63.5 | 1.5 2.0 | 84.5*1/6 97.3*1/6 |

| 3 1/2” 4” | 161 173 | 128 164 | 89 101.6 | 2.0 2.0 | 124.3*1/4 131.3*1/4 |