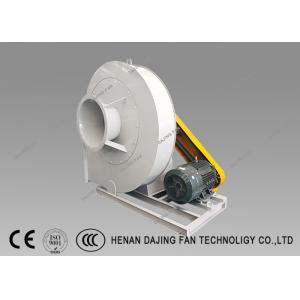

3 Phase High Pressure Air Blower Centrifugal Exhaust Fan Blower For Mine Ventilation

Add to Cart

3 Phase High Pressure Air Blower Centrifugal Fan For Forced Draft Mine Ventilation

The Model 9-19 and 9-26 high-pressure centrifugal fan is extensively applied to transmit materials. The transmission medium is air or other non-flammable gases, which are harmless to human. It is generally suitable for enforced high pressure ventilation in such industries as forging and smelting, glass, pottery, electroplating, battery and wireless sectors, etc. It is also used to deliver grain, fodder, ore powder, plastics, etc. in the processing industries. It is also suitable for the combined use with carton machinery and tempered glass equipment.

3 Phase High Pressure Air Blower Centrifugal Fan For Forced Draft Mine Ventilation | |||

| Centrifugal fan | Air Flow | 6000~41500 | m3/h |

| Pressure | 3500~1500 | Pa | |

| Rotating speed | 2900/1450/960 | r/min | |

| Material | Carbon steel | ||

| Motor | Power | 7.5~410 | kw |

| Voltage | 220/380/440/6000/6600 | v | |

| Frequency | 50/60 | hz | |

Application

Industrial systems such as Coal-fired power, Metallurgy,

Papermaking, Cement and Glass production, Chemical industry,

Material handling, Sewage treatment, Waste incineration, Subway

ventilation, environment protection, mine, metallurgy,

petro-chemical, tunnel,Industrial boiler and Dust removal systems

etc. , and wind tunnel. It is widely applicable for kitchen

exhaust, range hood or ventilation, air-exchange i

n the public places such as the unit canteens, guesthouses, restaurants, eating establishments etc. It is fit for use in the production equipments such as grain; chemical; plastic machineries and so on.

Optimized Design

The fan adopts advanced technology. The design of backward curved centrifugal wheel is optimized by means of CFD hydro-field simulating. The design is more accordant with the aerodynamic characteristics, high efficiency, and stable airflow.

Advanced Process

All steel laser cut blades are welded and positioned accurately. The overall strength of the blades are designed and welded to withstand long hours high speed operation.

High Balancing Level

Each wheel is subjected to dynamic balance test. The balancing level is kept at G4.0 (Typical products are balanced to G6.3 only). Durability, stability and quietness are guaranteed.

Wide Performance Range of High Efficiency

The wheel has stable and flat performance curves over a wide range of operating conditions which can efficiently avoid performance drop as the operating point moves up or down.

Centrifugal fan production process:

Case Show: