ISO90001 Hybrid Cure Polyester Epoxy Resin , saturated Polyester Resin Low Gloss

Add to Cart

Physical extinction Epoxy&Polyester Resin for low gloss powder paint

◇ Applications:

HH2583 is a carboxyl polyester resin designed for 50/50 hybrid powder coatings with low gloss.

Advantages of powder coatings

1. Health and environmental protection

All kinds of liquid chemical harmful film-forming, dispersion, wetting, leveling, anti-corrosion and anti mildew additives added to achieve coating performance are omitted.

2. Convenient transportation and storage

Ordinary coatings contain about 20-50% water or solvent, while powder coatings are completely solid without water or solvent, which is convenient and safe for transportation. In addition, coatings containing water or solvent tend to freeze when the transportation and storage temperature is lower than 0 ℃. This problem does not exist in powder coatings.

3. No preservative is required

In the traditional liquid coating, there is both water and bacterial food, which is easy to be polluted by bacteria. Therefore, in order to prevent deterioration, preservatives should be added, while latex powder coatings have no bacterial pollution and do not need preservatives

4. Paint smell

Compared with the general traditional coating smell residue, this coating can disperse quickly, which can be said to disappear immediately.

◇ Basic features:

Excellent extinction performance

Good mechanical properties

Good storage stability

Not suitable for high gloss coating.

◇ Specifications:

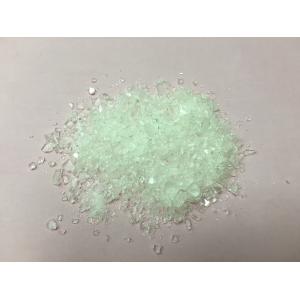

Appearance white or light yellow transparent flakes

Color(50%DMF) max:3

Acid number(mgKOH/g): 69~75

Softening point(℃) 93~103

Glass transition temp.( ℃) ~53

Melting viscosity(200℃, cone/plate, mPa·s): 3500~5500

Reactivity at 180℃(s, 50% Epoxy): 150~250

◇ Recommend Formulation:HH-2583—E12

| HH-2583 | E12 | Filler & pigment | Leveling agent | Benzoin | Carbon black | Matting agent |

| 270 | 270 | 384 | 10 | 4 | 6 | 48 |

◇ Extrusion Condition:

Two-screw extruder

Zone I: 90~110℃ Zone II: 110~120℃

Speed of revolution: 500~1200rpm

Fineness of powder: <100μm

◇ Application Condition:

Electrostatic spraying with: 40~70KV

Coating film thickness: 50~100μm

Degreased cold-rolled steel 0.5mm

◇ Curing Requirement: 180℃×15min. or 200℃×20min.

◇ Film Properties:

Gel time(180℃,sec): 50~150

Horizontal flow:(180℃),mm: 20~24

Gloss(60°): ≤10%

Bending(φ1mm): pass

Adhesive(1mm,grade): 0

Pencil hardness: 1H

Impact(50cm): +50, -40

Remarks:all the polyester resins could be customizes to Non-tin (A) ,anti gas burners(G),tribo gun(T) and anti-blooming(F)