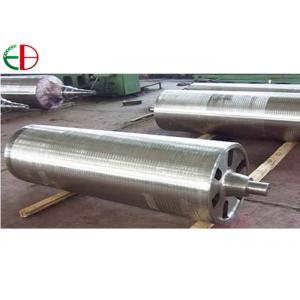

310S 2.4879 Heat Resistant Cast Steel Stainless Centrifugal Casting Furnace Roller

Add to Cart

310S 2.4879 Heat Resistant Cast Steel Stainless Centrifugal Casting Furnace Roller

Material Grade:

SCH17

ASTM

A297 HE

Cr29Ni9

ASTM A297 HK

Cr25Ni20

ZG40Cr25Ni20Si2

Cr25Ni14; HK2Co20;1.4852;1.4849;Cr14Ni9

Quality Level:

As per National Standard

International Standards

Production Process:

Investment Process

Centrifugal Process

Sand Process

Machining process.

Special Features:

Investment Process & Centrifugal Process & Sand Process.

Heat-treatment and machining process.

Heat steel castings as per GB/T 20878,DIN 17440,DIN 17224, AISI,ASTM,JIS SUH35,

NF A35-572/584,BS970,BS1449,ISO 683/13.

Heat-resistant Steel-Chromium ASTM A297

| Number | Steel Grade | Chemical Composition (%) | |||||||

| C | ≤Mn | ≤Si | ≤P | ≤S | Cr | Ni | ≤Mo | ||

| HF | Cr10NiS | 0.2-0.4 | 2.0 | 2.0 | 0.04 | 0.04 | 18-23 | 8-12 | 0.50 |

| HH | Cr25Ni12 | 0.2-0.5 | 2.0 | 2.0 | 0.04 | 0.04 | 24-28 | 11-14 | 0.50 |

| HI | Cr28Ni15 | 0.2-0.5 | 2.0 | 2.0 | 0.04 | 0.04 | 26-30 | 14-18 | 0.50 |

| HK | Cr25Ni20 | 0.2-0.6 | 2.0 | 2.0 | 0.04 | 0.04 | 24-28 | 18-22 | 0.50 |

| HE | Cr29Ni9 | 0.2-0.5 | 2.0 | 2.0 | 0.04 | 0.04 | 26-30 | 8-11 | 0.50 |

| HT | Cr15Ni35 | 0.35-0.75 | 2.0 | 2.5 | 0.04 | 0.04 | 15-19 | 33-37 | 0.50 |

| HU | Cr10Ni30 | 0.35-0.75 | 2.0 | 2.5 | 0.04 | 0.04 | 17-21 | 37-41 | 0.50 |

| HW | Cr12Ni60 | 0.35-0.75 | 2.0 | 2.5 | 0.04 | 0.04 | 10-14 | 58-62 | 0.50 |

| HX | Cr17Ni66 | 0.35-0.75 | 2.0 | 2.5 | 0.04 | 0.04 | 15-19 | 64-68 | 0.50 |

| HC | Cr23 | ≤0.50 | 1.0 | 2.0 | 0.04 | 0.04 | 26-30 | ≤4.00 | 0.50 |

| HD | Cr28Ni5 | ≤0.50 | 1.5 | 2.0 | 0.04 | 0.04 | 26-30 | 4 - 7 | 0.50 |

| HL | Cr29Ni20 | 0.2-0.6 | 2.0 | 2.0 | 0.04 | 0.04 | 28-32 | 18-22 | 0.50 |

| HN | Cr20Ni25 | 0.2-0.5 | 2.0 | 2.0 | 0.04 | 0.04 | 19-23 | 23-27 | 0.50 |

| HP | Cr26Ni35 | 0.35-0.75 | 2.0 | 2.5 | 0.04 | 0.04 | 24-28 | 33-37 | 0.50 |

Production Process

Step 2: Process design by technical department

Step 3: Purchase of raw materials and pattern making &checking

Step 4: Inspection of raw materials

Step 5: Melting by middle-frequency induction furnaces

Step 6: Ladle analysis by Spectrometer

Step 7: De-oxidization, slag-removal, tapping

Step 8: Pouring

Step 9: Openning & fettling

Step 10: Surface & dimensional check

Step 11: Heat treatment

Step 12: Inspection of physical property (UT test,MT test, hardness,impact value µstructure)

Step 13: Packing

Step 14: Shipping

1. 20-year Foundry Operation Experience.

2. Friendly & High Efficient Technical & Commercial

Communication.

3. Professional Export Practices: Have Exported to +60 Overseas

Countries.

Our Trade Show

Our booth No. 14-A29-5 in Newcast 2015,Germany

Hall 14, Stand No.A29-5.

Contact Us for further information about products & service:

Mr.John Liu

Project Manager

Tel: 0086-188 0059 6372

Fax: 0086-510-6879 2172

E-mail: cast@ebcastings.com, ebcastings@163.com

Skype ID:julia.zhu26

QQ: 217 039 6403

Eternal Bliss Alloy Casting & Forging Co.,LTD.

Add.: J-Sci-Tech Park, Binhu District,Wuxi,214122, Jiangsu,China