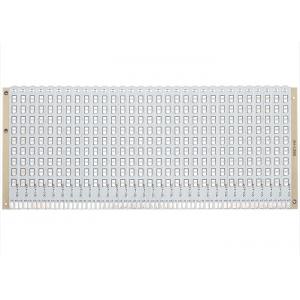

MultI Layer Liquid Hotoimageable Solder Mask , White Color PCB Etch Resist Ink

Add to Cart

White color liquid photoimageable curable solder resist mask

| Items | Technical features | Notes |

| Color | Green , Blue | |

| Fineness | ≤8µm | 0 ~25µm Fineness gauge |

| Viscosity (25℃) | 110±20dPa﹒s | VT-04F |

| Density (25℃) | 1.20 ~1.40 g/ml | |

| Screen mesh | 90 ~120T | |

| Film thickness | 12 ~16µm | |

| Curing energy | 1000 ~1800 mJ/cm2 | The effective value through the polyester film |

| Pencil hardness | ≥4H | Pencil hardness test |

| Adhesion | 100/100 | Laceration experiment |

| Insulation resistance | ≥1.0×108Ω | IPC-SM-840D 3.8.2 |

| Resistance to molten Tin | 260±5℃×10secends×3times OK | IPC-SM-840D 3.7.2 |

| Environment standard | In compliance with RoHS directives | SGS testing |

| Flammability | UL94V-0 | Certified number:UL-E189612 |

| Package | 5.0kg/bucket , 20kg/box | |

| Shelf time | 6 months since the date of manufacture | Store below 25℃ in dark |

Working procedure

1. Mixing

Mixing a small amount main agent with hardener and stirring thoroughly,then mixing the mixture above with the remanent main agent,add appropriate diluent and stirring 5-10 minutes. The viscosity of ink is adjusted to 120 PS if printed by hand. And it is adjusted to 180 PS if printed by machine.It is adjusted to 200 PS if it is aluminum tamponade .The viscosity of ink mixed above is measured at 25 degrees. Please use the special diluent of our company if the viscosity of ink needs to adjust.

- Remain time

10-15 minutes after stiring uniformly

- Ordinary boards:43T;Chemical-plating Aurum or Tin boards:36T

- Pre-baking

1) Single side printing separately

First side:72-76 degrees,15-18 min

Second side:72-76 degrees,30-35 min

- Double sides printing simultaneously:72-76 degrees,40-60min

- Exposure

300-500mJ/cm2,Black ink:600-750mJ/cm2,exposure step:10-12 steps

- Developing:

Developing solution:0.8-1.2wt% Na2CO3 or K2CO3 aqueous solution

Developing solution temperature:28-32 degrees

Spray pressure:1.5-2.5kg/cm2

Developing time:40-90 seconds

- Post cure

Spray Tin board:150 degrees*(60-120min)

Chemical-plating Aurum board:150 degrees*(50-60min)

Thick copper plate,boards printed with black ink should be post-black in subsection:75 degrees*(60-120min)+100 degrees*30 min+150 degrees*(60-90min)

- Safe time

6 months since the date of manufacture,store below 25 degree in dark

- Attention:

1) Mixing the ink fully before using

2) We will offer you special diluent or PMA if the ink need dilute

3) The values above are based on experiments in our lab.Experiments need to be carried out in order to get proper using condition.