Flame Resistance Fire Testing Equipment Laser System Support ISO5660 Standard

Add to Cart

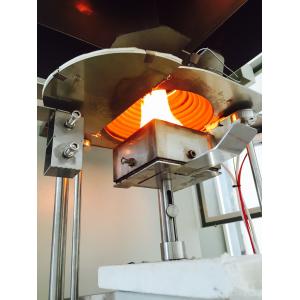

cone calorimeter

A cone calorimeter is a fire test tool that is based on the amount of heat released during the combustion process directly related to the oxygen consumption in the combustion process. The amount of heat generated is directly proportional to the severity of the fire, such as the rate of fire growth. In order to obtain the flammability of the material, this is exposed to an external radiation heat source. Therefore, since this is a forced combustion test, the cone value is generally considered to reflect the second ignitability of the ignition.

Core advantages:

1). Displays the instrument status.

2). Calibrate the instrument and store the calibration results.

3). Collect the test data.

4). Calculate the required parameters.

5) Display the results by the standard way.

6). Multiple tests are averaged.

7). Data entry to FDMS (Fire Data Management System) - Most

European and US laboratories apply the system format, sharing data

between different laboratory calorimeters.

8). the file output is in CSV (Comma Separated File) format, which

can be quickly converted to a spreadsheet

Applicable Standards:

ISO5660,ASTM E 1354, ASTM E 1474, ASTM E 1740, ASTM F 1550, ASTM D

6113, NFPA 264, CAN ULC 135, BS 476

Accord with standard:ISO 5660 /ASTM E 1354/GB T16172

Technology data:

1.) 19inch standard instrument frame,17inch touchable screen pc insert

2.) cone heater powering rating:5000w,heat output rate:0~100kw/m2

3.) in the range of 50*50mm in the center surface of expose test sample ,center irradiation error no more than +-2%;

4.) sample size:100mm*100mm*50mm

5.) weight range:0~2000g;precision:0.1g;

6.) ignition system with safe cut device high pressure spark generator ,automatic positioning

7.) clockwise magnetic oxygen analyzer ,adopt pressure change of clockwise magnetic to measure the oxygen density

8.) density range:0-25%,T90<1.5S,zero drift:<0.5%month,measure data deviation<0.5%month,

9.) non-dispersion infrared co and co2 analyzer:co:0~1%;co2:0~10%;

10.) smoke analyzer use laser system test smoke density,and this system was made up of photoelectricity two-electrode valve,0.5mv He-Ne laser,main graphics detector and auxiliary graphics detector .

11.) exhaust system was made up of fan,hottle,air intake and exhaust tube of fan and orifice meter.exhaust gas flow 0~50g/s can be adjusted,precision 0.1g/s.

12.) ring sampler need to be located in the air take tube at distance of 685mm against hottle ,need to be 12 holes existed in the sampler in order to homogeneous air flow component.

13.) exhaust gas flow need to be measured by the differencial pressure of side of hole plate above the fans at the distance of 350mm,the inner diameter of hole plate is 57mm+-1mm;

14.) the temperature of air flow is tested by armored thermocouple with closed node of diameter 1.6mm,thermocouple need to be located in 100 mm above the orifice plate;

15.) gas sampling system including ring sampler ,sampling pump,filter,cold trap,waste water exhaust,water filter and co2 filter;

16.) cold trap:0~5 degree,diaphragm pump,flow rate :261/min,vacuum degree:700mm Hg,pressure:2.5bar

17.) temperature controller instrument can be automatically adjust in 0-1000℃,both setted resolution and temperature control precision is +-2degree,and supply automatic cold end compensator with thermocouple

18.) use carton foil type heat flow meter ,design range 0~100k w/m2,diameter of radiation receiving target is

12.5mm,surface with durable dull black coating.radiation receiving target is cooling water method. Precision

of heat flow meter is 3%,repeatability is +0-0.5%,attached a adjust report can be date back to NIST.

19.) supply portable cooling water system.when use heat flow meter ,users do not need to tap and equipped with water.

20.) In order to calibrate the response of the whole test system, a square hole with a square hole and a square yellow copper tube is used as the calibration burner for measuring the C- coefficient values.

21.) Data acquisition system should be able to record the oxygen analyzer, orifice meter, thermocouple and other instruments of the output.

22.) Equipped with software operating system, the test results include: heat release rate, gas flow rate, C coefficient, sample time and time, total oxygen consumption, total smoke, mass loss rate, total heat release, effective combustion heat, carbon dioxide emissions and carbon dioxide emissions.

Soft ware instruction of cone calorimeter:

1.) Set in order to calibrate the sensor, including the oxygen analyzer, carbon dioxide analyzer, carbon monoxide analyzer, micro pressure difference sensor, smoke density measurement system, weighing device, mass flow control single or double point calibration, in order to obtain the best linear;

2.) C- coefficient calibration, the software can automatically set the C coefficient measurement of gas flow, such as 1KW, 3KW or 5KW, the computer system automatically calculates the ISO 5660 C coefficient and the average C coefficient, and can save the record;

3.) The software can automatically generate the C- coefficient log, which is convenient for the user to view the history of the cone calorimeter, and to identify the accuracy and stability of the system;

4.) The system can automatically calculate the delay time of the oxygen analyzer, the carbon dioxide analyzer and the carbon monoxide analyzer, which is convenient for the synchronous calculation

5.) Status check interface, the working state of the various sensor components of the instrument can be clear at a glance;

6.) Can record the work value of each sensor, including micro pressure difference sensor, chimney temperature, oxygen analyzer, carbon dioxide analyzer, carbon monoxide analyzer;

7.) The report template is EXCELL format, which can display graphics and numerical model.

Structure of cone calorimeter

1.) The combustion chamber: the conical heater, the 10KV ignition device, the control circuit, the windshield, etc..

2.) Oxygen analyzer: Servomex analyser, oxygen analyzer can accurately test the content of oxygen in the air pipe in the time of the change, and then by the instantaneous oxygen concentration and oxygen consumption principle to determine the heat release of the material.

3.) Load table: a device for measuring the quality of the sample, which can accurately record the mass change of the sample in the process of combustion

4.) Smoke measurement system: He Ne laser emitter and double electron beam measuring device, which can be used to determine the specific extinction area (SEA) of the smoke in the smoke pipe.

5.)Ventilation system: the ventilation system is a sample of the combustion products from the combustion chamber to the atmosphere in the device

6.) Other improvement equipment: according to different needs, can also add other analysis device, such as the analysis of the combustion products, can increase the infrared spectrum analysis device; if the temperature distribution in the sample, the corresponding thermocouple or infrared imaging device.

7.) Auxiliary equipment: auxiliary equipment includes microcomputer processor, heat flow meter device, removing CO2 and H2O (gas), etc.

Sample size | 100*100*50mm |

Weight range | 0-200g |

precision | 0.1g |

Density range | 0-25% |

T90 | <1.5S |

Zero drift | <0.5%month |

Measure data deviation | <0.5%month |