Add to Cart

Corrosion resistant Alloy X (N06002) bar, forging, section, plate, wire, pipe for gas turbine engine etc

1 PRODUCT

Corrosion resistant Alloy X for gas turbine engines for combustion zone components such as transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. etc.

Product forms available as castings, rod, bar, forgings, forging block, extruded section, plate, sheet, strip, wire, pipe and tube etc.

2 EQUIVALENT DESIGNATION

GH3536, UNS N06002, AMS 5754, 5798, W.Nr.2.4613, 2.4665, NC22FeD(France),NiCr22Fe18Mo(DIN),Nimonic PE13(UK), Inconel® alloy HX, Hastelloy® X

3 APPLICATION

Alloy X has a wide use in gas turbine engines for combustion zone components such as transition ducts, combustor cans, spray bars and flame holders as well as in afterburners, tailpipes and cabin heaters. It is recommended for use in industrial furnace applications because it has unusual resistant to oxidizing, reducing and neutral atmospheres. Furnace rolls of this alloy were still in good condition after operating for 8700 hours at 2150°F (1177°C). Alloy X is also used in the chemical process industry for retorts, muffles, catalyst support grids, furnace baffles, tubing for pyrolysis operations and flash drier components.

4 OVERVIEW

Alloy X is an austenitic solid solution strengthened nickel based alloy comprising of 22% chromium for excellent resistance to oxidation at the elevated temperatures.

Alloy X offers outstanding strength at high temperatures. It has great high temperature and stress rupture characteristics above 790℃ or 1450℉. It is suitable for use in applications at temperature limits about 1200℃ or 2200℉. Alloy X has high magnitudes of chromium, nickel and molybdenum that offer excellent corrosion resistance properties similar to high nickel alloys more commonly in corrosion applications.

Alloy X is basically known for providing high heat and oxidation resistance as well as excellent resistance to chloride stress corrosion cracking and outstanding resistance to reducing and carburizing conditions. It has been noticed to be extremely resistant to stress corrosion cracking in the petrochemical applications.

5 CHEMICAL COMPOSITION (wt%):

Table 1

| Fe | Ni | Co | Cr | Mo | Ti | Nb | B |

| 17.0-20.0 | Balance | 0.5-2.5 | 20.5-23.0 | 8.0-10.0 | ≤0.15 | ≤0.50 | ≤0.008 |

| Cu | C | Al | Mn | Si | P | S | W |

| ≤0.50 | 0.05-0.15* | ≤0.50 | ≤1.00 | ≤1.00 | ≤0.025 | ≤0.015 | 0.20-1.00 |

* Note casting could be 0.20.

6 METALLURGICAL STRUCTURE

Alloy X is basically a single phase alloy possessing face centered cubic structure and receives its strength basically by solid solution strengthening from the elements chromium, molybdenum and tungsten. The presence of large chromium concentration, it offers outstanding resistance to oxidation at temperatures above 982°C or 1800°F.

Solid solution strengthened Alloy X is offered in the solution heat processed form. In this form, microstructures normally comprise of primary carbides distributed in a single phase matrix with necessarily clean grain limits.

7 PHYSICAL PROPERTIES

Density: 0.297 lb/in3 (8.22 g/cm3)

Melting range: 2300-2470°F (1260-1355°C)

8 OXIDATION RESISTANCE

Comparative Static Oxidation Data in Flowing Air for 1008 Hours*

| Alloy | 1800°F (980°C) | 2000°F (1095°C) | ||||||

| Metal Loss/Side | Metal Loss CIP**/Side | Metal Loss/Side | Metal Loss CIP**/Side | |||||

| mils | mm | mils | mm | mils | mm | mils | mm | |

| Alloy X | 0.29 | 0.007 | 0.74 | 0.019 | 1.5 | 0.038 | 2.7 | 0.069 |

| Alloy 600 | 0.32 | 0.008 | 0.9 | 0.023 | 1.1 | 0.028 | 1.6 | 0.041 |

| Alloy 601 | 0.53 | 0.013 | 1.3 | 0.033 | 1.2 | 0.031 | 2.6 | 0.06 |

| Alloy 625 | 0.32 | 0.008 | 0.72 | 0.018 | 3.3 | 0.083 | 4.8 | 0.12 |

| Alloy 800H | 0.024 | 0.024 | 1.8 | 0.046 | 5.4 | 0.137 | 7.4 | 0.19 |

*Cycled to room temperature once a week

**CIP=Continuous Internal Penetration

9 CORROSION RESISTANCE

Comparative average hot corrosion resistance*

| Test Temperature | Test Period | Total Metal Affected/Side | ||||||

| Alloy X | S | 188 | ||||||

| °F | °C | h | mils | mm | mils | mm | mils | mm |

| 1650 | 900 | 200 | 3 | 0.08 | 2.7 | 0.07 | 2.1 | 0.05 |

| 1650 | 900 | 1000 | 6.8 | 0.17 | 7.5 | 0.19 | 3.7 | 0.09 |

*All tests performed by exposure to the combustion products of No. 2 fuel oil (0.4 percent sulfur) and 5 ppm of sea salt. Gas velocity over samples was 13 ft./sec. (4m/s). Thermal shock frequency was one/hour.

10 MECHANICAL PROPERTIES

Hardness

Room temperature hardness of material solution annealed at 2150°F(1177℃)

| Form | Hardness, HRB | Typical ASTM Grain Size |

| Sheet | 86 | 3 - 5 |

| Plate | 87 | 3.5 - 6 |

| Bar | 88 | 2 - 5 |

Tensile data of plate

| Test Temperature | Yield Strength 0.2% | Ultimate Tensile Strength | Elongation | |||

| °F | °C | ksi | MPa | ksi | MPa | % |

| 70 | 21 | 49.3 | 340 | 110.2 | 760 | 48.9 |

| 1000 | 538 | 32.5 | 224 | 87.6 | 604 | 60.2 |

| 1200 | 649 | 30.7 | 212 | 80.9 | 558 | 63.5 |

| 1400 | 760 | 31.6 | 218 | 61 | 421 | 74.5 |

| 1600 | 871 | 27.4 | 189 | 37 | 255 | 98.1 |

| 1800 | 982 | 13.6 | 94 | 20 | 138 | 98.1 |

| 2000 | 1093 | 6.5 | 45 | 10.4 | 72 | 95.3 |

Impact strength

Aged plate

| Aging temperature | Aging time | Average charpy V-Notch impact strength | ||

| °F | °C | h | ft.-lb. | J |

| SHT | SHT | - | 95 | 129 |

| 1200 | 649 | 1000 | 24 | 33 |

| 4000 | 12 | 16 | ||

| 8000 | 15 | 20 | ||

| 1400 | 760 | 1000 | 10 | 14 |

| 4000 | 10 | 14 | ||

| 8000 | 8 | 11 | ||

| 1600 | 871 | 0 | 15 | 20 |

| 4000 | 12 | 16 | ||

| 8000 | 15 | 20 | ||

| 16000 | 12 | 16 | ||

11 HEAT TREATMENT

Wrought forms of Alloy X are furnished in the solution heattreated condition unless otherwise specified. It is typically solution heattreated at 2150°F (1177°C) and rapid cooled. Bright annealed products are cooled in hydrogen. Annealing at temperatures lower than the solution heat treating may cause precipitation of secondary phases, which may affect the alloy’s strength and ductility.

Heat processing done at temperatures lower than the solution processing temperature is called as mill annealing. It should be kept in mind that implementing mill annealing heat processing will often provide the precipitation of the secondary carbides on the grain edges of the material and it will not recover the material to the as-received conditions.

12 WORKMANSHIP

Hot working

Alloy X can be hot processed into several forms, although they can be more susceptible to the magnitude and rate of hot reduction than is for austenitic stainless steels. Besides, hot processing temperature limits for these alloys can be narrow. The hot temperature limits for Alloy X – furnace temperature: 2150°F or 1175°C and lowest temperature: 1750°F or 955°C.

Cold working

Alloy X is readily formed in the different shapes through cold processing. As it is stronger and work harden more quickly than austenitic stainless grades, larger force is often needed to attain the identical magnitude of cold distortion. The larger yield strength may also offer larger spring back while cold forging than observed for stainless steels. Moreover, the quick work hardening features of this alloy may need more rapid moderate annealing in the forming steps to produce a finished component.

13 STANDARD SPECIFICATION

It is listed in NACE MR0175.

Chemical composition

DIN 17744

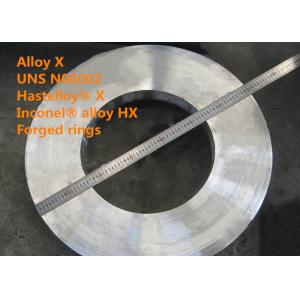

Forging

ASTM B564 / AMS 5754

DIN 17754

ISO 9725

Billet, bar, rod

ASTM B472 / ASTM B572

AMS 5754

DIN 17752

ISO 9723

Wire

AMS 5798

DIN 17753

ISO 9724

Plate,Sheet, Strip

ASTM B435

AMS 5536

DIN 17750

ISO 6208

Tubular

ASTM B619 / ASTM B622 / ASTM B626 / ASTM B751 / ASTM B775 / ASTM B829

AMS 5587 / AMS 5588

DIN 17751

ISO 6207

Disc, Ring

AECMA PrEN2184

Casting

AMS 5390E

Fitting

ASTM B366 / ASME SB366

14 COMPETITIVE ADVANTAGE

(1) More than 50 years experience of research and develop in high

temperature alloy, corrosion resistance alloy, precision alloy,

refractory alloy, rare metal and precious metal material and

products.

(2) 6 state key laboratories and calibration center.

(3) Patented technologies.

(4) Ultra-purity smelting process: VIM + IG-ESR + VAR

(5) Excellent high performance.

15 BUSINESS TERM

| Minimum order quantity | Negotiable |

| Price | Negotiable |

| Packing details | Water prevent, seaworthy transport, non-fumigation wooden box or pallet |

| Mark | As per order |

| Delivery time | 60-90 days |

| Payment terms | T/T, L/C at sight, D/P |

| Supply ability | 100 metric tons / Month |