Camera Taconic SMT Prototype Assembly , SMT Electronic Assembly IPC-II Standard

Brand Name:China chao sheng

Certification:ISO/UL/RoHS/TS

Model Number:Six layers of soft and hard PCBA

Minimum Order Quantity:1PCS

Delivery Time:20-25day

Payment Terms:T/T, Western Union

Contact Now

Add to Cart

Active Member

Location:

Hong kong Hong kong China

Address:

Huishang Building, 19-128 Nathan Road, Yau Tsim Sha Tsui, Yau Tsim, Hong Kong

Supplier`s last login times:

within 48 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

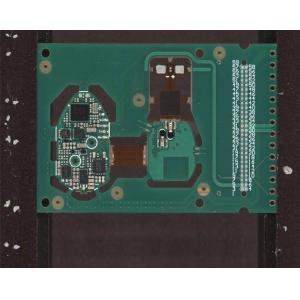

Six layers of soft and hard combined production circuit test,wooden box carton packaging,SMT PCB Service,taconic pcb

Product Description

- Six layers of soft and hard combined production + SMT, PCBA wooden box carton packaging,SMT PCB Service,taconic pcb

- PCBA processing method

- PCB production + it contains SMT, DIP, TEST,

- RoHS Lead Free Control Board SMT PCB Assembly 1.6mm PCB Service

Printed circuit board (pcb) and PCBA products

Communication terminal, communication station, electronic communication, optical fiber, optical module, communication equipment, communication instrument, computer, household appliance, testing equipment, testing instrument, instrument, SD card, SG card, mobile phone, computer, various antennas, cars, music Equipment, playback equipment, banking equipment, medical instruments, medical equipment, medical equipment, aerospace, aviation, military, LED, OLED, OLCD power control power supply, industrial power supply, communication power supply, automotive power supply, office equipment, digital products,computers,etc.Applications;

Flexible circuit board (FPC) and FPCA product areas

CD, hard disk, printer, fax machine, scanner, sensor, mobile phone, connector, module, walkie-talkie antenna card, high-end camera, digital camera, laser head, CD, medical, instrumentation, drive, automotive instrumentation, medical instrument, Medical equipment, banking equipment, industrial instruments, LED light bars, military, aviation, aerospace, defense and other high-tech products, of which more than 70% of the products are exported to Europe, America, Europe, Central Europe, Western Europe, Southeast Asia, Asia-Pacific and other countries and area.

Technical requirement:

- Professional surface-mounting and through-hole soldering technology

- Various sizes are available, like 1206, 0805, 0603 components SMT technology

- ICT (in circuit test), FCT (functional circuit test) technology

- PCB assembly with UL, CE, FCC and RoHS approvals

- Nitrogen gas reflow soldering technology for SMT

- High standard SMT and solder assembly line

- High density interconnected board placement technology capacity

Quote requirement:

- Gerber file of the bare PCB board

- BOM (bill of material) for assembly

- To short the lead time, please kindly advise us if there is any acceptable components substitution

- Testing guide and test fixtures if necessary

- Programming files and programming tool if necessary

- Schematic if necessary

- OEM/ODM/EMS services for PCBA:

- PCBA, PCB assembly: SMT, PTH and BGA

- PCBA and enclosure design

- Components sourcing and purchasing

- Quick prototyping

- Plastic injection molding

- Metal sheet stamping

- Final assembly

- Test: AOI, in-circuit test (ICT), functional test (FCT)

- Custom clearance for material importing and product exporting

Specifications

- Layer: 4 layer

- Material: FR4

- Board Thickness: 1.6mm

- Surface Treatment: Lead free HASL

- Solder Mask: Green

- Size: 123mm*36mm

- Copper Thickness: 1.5oZ

- Min. Hole Size: 0.15mm

- Min. Line Width: 0.08mm

- Min. Line Spacing: 0.08mm

- Hole vias: Buried hole and blind hole

Orientronic PCB assembly equipmet

- Fully automatic SMT stencil printer: FolunGwin Win-5

- SMT machine: Siemens SIPLACE D1/D2/Siemens SIPLACE S20/F4

- Reflow oven: FolunGwin FL-RX860

- Wave soldering machine: FolunGwin ADS300

- Automated optical inspection (AOI): Aleader ALD-H-350B

- Needed:

- PCB gerber file

- BOM list for PCB assembly

- Send us your sample PCB board or PCBA

- Advantages:

- Turnkey manufacturing or quick-turn prototypes

- Board-level assembly or complete system integration

- Low-volume or mixed-technology assembly for PCBA

- Even consignment production

- Supported capabilities

- Type of assembly:

- THD (thru-hole device)/conventional

- SMT (surface-mount technology)

- SMT and THD mixed

- Double-sided SMT and/or THD assembly

- Components:

- Passives, smallest size 0201

- Fine pitch to 08 Mils

- Leadless chip carriers/BGA, VFBGA, FPGA and DFN

- Connectors and terminals

- Component packaging:

- Reels

- Cut tape

- Tube

- Loose parts

- Board dimensions:

- Smallest size: 0.25 x 0.25 inch/6 x 6mm

- Largest size: 15.75 x 13.5 inches/400 x 340mm

- Board shape:

- Rectangular

- Round

- Slots

- Cutouts

- Complex

- Irregular

- Board type:

- Rigid

- Flexible

- Rigid-flexible

- Solder type:

- Leaded and lead-free

- Water soluble solder paste

- Manual soldering for special parts, such as wires and temperature sensitive parts

- Design file format:

- Gerber RS-274X, 274D, Eagle and AutoCAD’s DXF, DWG

- BOM (bill of materials)

- Pick and place file (XYRS)

PCB, FPC process production capability

| Technical ltem | MassProduct | Advanced Technology | |||||

| 2016 | 2017 | 2018 | |||||

| Max.Layer Count | 26L | 36L | 80L | ||||

| Through-hole plate | 2~45L | 2~60L | 2~80L | ||||

| Max.PCBSize(in) | 24*52" | 25*62" | 25*78.75" | ||||

| The layer number of FPC | 1~36L | 1~50L | 1~60L | ||||

| Max.PCBSize(in) | 9.8"*196" | 9.8"*196" | 10"*196"Reel to reel | ||||

| Layeredplatelayer | 2~12L | 2~18L | 2~26L | ||||

| Max.PCBSize(in) | 9"*48" | 9"*52" | 9"*62" | ||||

| Combination of hard and soft layers | 3~26L | 3~30L | 3~50L | ||||

| Interconnect HDI | 5+X+5Interconnect HDI | 7+X+7Interconnect HDI | 8+X+8,Interconnect HDI | ||||

| HDI PCB | 4~45L | 4~60L | 4~80L | ||||

| Interconnect HDI | 3+20+3 | 4+X+4Interconnect HDI | 4+X+4,Interconnect HDI | ||||

| Max.PCBSize(in) | 24"*43" | 24"*49" | 25"*52" | ||||

| Material | FR-4 Rogers | FR-4 Rogers | FR-4 Rogers | ||||

| Base material | Halogenfree,LowDK | Halogenfree,LowDK | Halogenfree,LowDK | ||||

| Build-up Material | FR-4 | FR-4 | FR-4 | ||||

| BOard,Thickness(mm) | Min.12L(mm) | 0.43 | 0.42~8.0mm | 0.38~10.0mm | |||

| Min.16L(mm) | 0.53 | 1.60~8.0mm | 0.45~10.0mm | ||||

| Min.18L(mm) | 0.63 | 2.0~8.0 | 0.51~10.0mm | ||||

| Min.52L(mm) | 0.8 | 2.50~8.0mm | 0.65~10.0mm | ||||

| MAX(mm) | 3.5 | 10.0mm | 10.0mm | ||||

| Min.CoreThickness um(mil) | 254"(10.0) | 254"(10.0) | 0.10~254(10.0mm) | ||||

| Min.Build up Dielectric | 38(1.5) | 32(1.3) | 25(1.0) | ||||

| BaseCopperWeight | Inner Layer | 4/1-8 OZ | 4/1-15 OZ | 4/1-0.30mm | |||

| Out Layer | 4/1-10 OZ | 4/1-15 OZ | 4/1-30 OZ | ||||

| Gold thick | 1~40u" | 1~60u" | 1~120u" | ||||

| Nithick | 76~127u" | 76~200u" | 1~250u" | ||||

| Min.HOle/Land um(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) | ||||

| Min.Laser via/landum(mil) | 60/170(2.4/6.8) | 50/150(2/6) | 50/150(2/6) | ||||

| Min. IVH,Hole size/landum(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) | ||||

| DieletricThickness | 38(1.5) | 32(1.3) | 32(1.3) | ||||

| 125(5) | 125(5) | 125(5) | |||||

| SKipvia | Yes | Yes | Yes | ||||

| viaoNhie(laserviaon BuriedPTH) | Yes | Yes | Yes | ||||

| Laser Hole Filling | Yes | Yes | Yes | ||||

| Technicalltem | Mass Product | Advanced Technolgy | |||||

| 2017year | 2018year | 2019year | |||||

| Drill hole depth ratio | ThroughHole | 2017year | .40:1 | .40:1 | |||

| Aspet Ratio | Micro Via | .35:1 | 1.2:1 | 1.2:1 | |||

| Copper Filling Dimple Size um(Mil) | 10(0.4) | 10(0.4) | 10(0.4) | ||||

| Min.LineWidth&space | lnner Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) | |||

| Plated Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) | ||||

| BGAPitch mm(Mil) | 0.3 | 0.3 | 0.3 | ||||

| Min.PTH Hole ring um(mil) | 75(3mil) | 62.5(2.5mil) | 62.5(2.5mil) | ||||

| Line Width Control | ∠2.5MIL | ±0.50 | ±0.50 | ±0.50 | |||

| 2.5Mil≤L/W∠4mil | ±0.50 | ±0.50 | ±0.50 | ||||

| ≦3mil | ±0.60 | ±0.60 | ±0.60 | ||||

| Laminated structure | Layer by layer | 3+N+3 | 4+N+4 | 5+N+5 | |||

| Sequential Build-up | 20L Any Layer | 36L Any Layer | 52L Any Layer | ||||

| Multi-layer overlay | N+N | N+N | N+N | ||||

| N+X+N | N+X+N | N+X+N | |||||

| sequential Lamination | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 | ||||

| Soft and hard bonding | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 | ||||

| PTH filling process | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | ||||

Camera Taconic SMT Prototype Assembly , SMT Electronic Assembly IPC-II Standard

Inquiry Cart

0