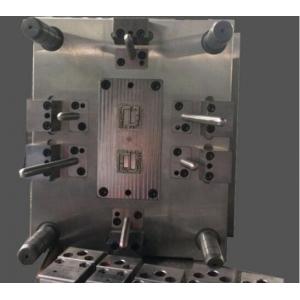

Standard Dme Mold Base Injection Moulding Single Or Multiply Cavity

Add to Cart

High precision high quality Standard mold base injection mould base,OEM mould base

All these components shoule be machined with high precision. There

are some famous mold base brand, like DME, HUSKY, LKM, FUTABA. In

order to save the cost, some mold makers do the mold base by

themselves, abviously the quality would be very bad, but some

clients thought that is the capability of a large mould

manufacturer, that is funny.

Mold base is comprised of four parts:

Fixed part – Including top plate and fixed plate(A plate)

Moving part – Including bottom plate, moving plate(B plate),

cushion plate, return pin, ejector retainer plate and ejector plate

Guiding part – Guiding pins and guiding bushing

Connecting part – Screws

Specifications

mould base, LKM standard mould base, HASCO standard mould base, DME

standard mould base, LKM mould base, HASCO mould base

Located in YUYAO city. Zhejiang province. China. We are committed

to continued growth and development. With rich experience in tool

& plastic industry. Has become one of the leading manufacturers

of molds and plastic products.

What We Do

Plastic Injection molds. tools making Clear acrylic Injection molding Prototyping and model making Plastic Printing & Welding & Assembly Product 2D&3D design.Reverse-engineering.etc

What We Believe

High quality is the only factor we consider Innovation reduces the cost,increase capacity One-stop solution assures the satisfaction of customer.

We expert in development and fabrication of various high quality

moulds with advanced technology and tooling equipments.

High-speed CNC machine Engraving machine Mirror EDM machine Milling and Grinding machine Slow W-EDM machine

Located in yuyao city. two hours to shanghai international airport

Over 100 experienced skilled workers More than 500 sets capability each year 90% of molds exported to US and Europe.

We provide one-stop solution from drawings design to final parts

PMMA.ABS.PP.PC.PS.PBT.etc Injection machines equipped with robots Feeders & Dryers. Temp. controlers Assembly line with silk-screen & painting

Advanced CAD and CAM software is adopted in the tool making

process.Operated by our experienced engineers.

Moldflow Pro-Engineer Solidworks Unigraphic Auto-CAD

| Mould material | SKD11, ASP-23,SKH9, SKD61,P20,NAK80,8402,8407 |

| Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61 |

| Cavity | Single / Multi per request |

| Runner | Hot / Cold |

| Mould life | 300,000-500,0000shots |

| Maximum mould size | 1500*1500 mm |

| surface request | EDM & High Polish |

| Design software | UG,PROE,CAD etc. |

| Plastic material | PP,PC,PE,ABS,PVC etc. |

| Plastic products | Electronic: Wireless receiver plastic part, 3G/4G Modem Wireless Network Cards,USB housing. Automotive interior parts: connector, navigation frame, car key. All kinds of connectors, digital parts. |

| Lead time | 20-60days |

| Specification | Depends on customer’s requirements |

| Payment terms | T/T, L/C,Paypal, Western Union |

| Trade terms | FOB Shanghai,CIF |

| MOQ | 1 set |

| Injection machine type | High speed machine,80T,120T,150T,200T,250T,350T,500T,800T |

| Package | Wooden/Plywood case for tool ,PE bags add export carton for parts |

| Value-added service | Polish,texture,painting,screen printing,turnkey project |

APPLICANCE