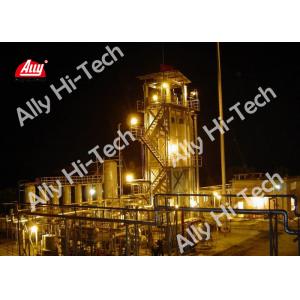

Small Scale On Site Hydrogen Generator , Natural Gas Hydrogen Generator

Add to Cart

Small Scale On Site Hydrogen Generator, Natural Gas Hydrogen Generator

Ally Hi-Tech optimized the process of SMR, incluidng the reformer, heat exchange network (HEN) and purification system, to reduce both capital investmetn and natural gas consumption, on the basis of the gas preparation system of ammonia synthesis process. Typically, Ally Hi-Tech has been engaged in the optimization of the reformer and granted more than 6 patents in this field. Ally Hi-Tech provided the hydrogen solution with a capacity of 50 NCMH for Beijing Olympics based on the SMR process associated with PSA in 2008.

Features

Mature production technology, safe and reliable operation.

Safe and practical operation control with high degree of automation.

Low operating costs and short payback period.

Off-gas of PSA recovered as fuel reduces both fuel consumption and exhaust emissions.

Pre-fabrication skid

suitable for the hydogen refueling station.

Process Schematic

Process Description

Desulphurization gas is mixed with steam as per a certain ratio. The mixutre flows through the Reformer Tubes, where it converts into syngas consisting of hydrogen and carbon monoxide and carbon dioxide and unreacted methane and steam in the presence of catalyst. A heat exchange system is used as economizer, while a shift convertor is introducted to convert carbon monoixed into extra hydrogen and carbon dioxide. The resulting gas enters into a PSA unit, where the hydrogen is separated from the other gases. The off-gas of PSA is recovered as fuel.

Reaction

CH4+H2O →3H2+CO - Q

CO+H2O → H2+CO2+Q

Performance

Hydrogen Capacity: 400 kg/d ~ 1,200 kg/d

Hydrogen Purity: 99% ~ 99.999% (v/v)

Hydrogen Pressure: 1.3 ~ 3.0 MPa(G)

Temperature: ambient

Reference