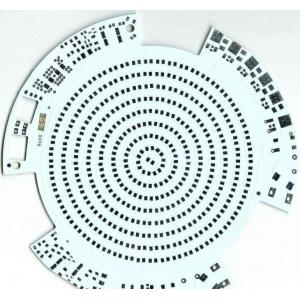

MCPCB IMS Insulated Metal Substrate Process Automated Optical Inspection

Add to Cart

Metal Core Pcb process quality control ims pcb automated optical inspection

Product Details

Metal Core Pcb process quality control ims pcb automated optical inspection

Material: Aluminum

OSP,HASL,plated Ni/Au,OSP/ ENIG/ Im Ag/ HASL/ Golden finger

Blue.green.red.black.white.etc,Clients required,White Black Yellow Green Red etc

Product capability

| Capability for PCB Products | |

| Item | Description |

| Layer | from 2-layer to 18-layer, we can make sample up to 20-layer. |

| PCB Type | Rigid board, FPC, Flex-rigid board, Aluminum board |

| Raw Material | FR4(tg135,tg150,tg170,tg180),Shengyi,ITEQ,KB and Nanya.Nelco,ISOLA,FR406,FR408,Rogers,Polyclad,Arlon |

| Surface Finishing | HASL,Leadfree,HASL,Immersiongold,immersion silver,immersion tin,hard gold,gold finger and so on |

| Special Technology | HDI board with structure (1+n+1, 2+n+2,3+n+3),min hole 0.1mm with laser drill. Min hole 0.15mm with mechanical drill. Max board size 630mmx1000mm, impedance control. |

| Copper | from 35um(1oz) up to 455um (13oz) |

| Product Application | Industrial, automobile, medical equipment, power supply etc. |

Our Company

1,FOUND is a Shenzhen-based PCB manufacturer and PCB assembler. Shenzhen has been for decades the world's center of electronics R&D and manufacturing. By skipping all the middle companies, we are successfully passing the savings and bringing a total satisfaction of PCB/PCBA purchasing experience to our valued customers.

2,all the boards will go through the most stringent tests other

than the basic visual check. FOUND adopt most of the testing and

inspecting equipments used in the industry, such as Flying Probe

Tester, X-Ray Inspection Machine, Automated Optical Inspection

(AOI) Machine. SPEED SUPER are having experienced engineers on the

process line

3,The company adopts qualified raw materials in strict accordance

with customer standards, and the production process is also in

strict accordance with international standards, strict process

quality control system to ensure the final product quality.

4,pricing structure is transparent and has no hidden cost in it

5,On-time Shipping

we are proud to have been always keeping an on-time delivery. We

work in three shifts to make sure your PCBs will be on your desk as

scheduled

6, 24 hours Customer Service

Whenever you have any problems, you can always reach a customer

service person to respond to your emails or messages. service

people will follow your orders from the time you submit your Gerber

file until to the time you receive your PCB and assembled PCBs

Our vast experience and knowledge in PCB Fabrication has covered

work for almost all industry sectors, including the following:

Military,Aerospace,Security,Medical,Commercial,Industrial,Broadcasting,

etc.

Advantages

1 One stop service.

Product design requirements build --> Circuit design --> PCB

design --> MCU program --> Sample making and testing -->

Component sourcing and purchase --> Small quantity produce

--> Bulk quantity produce --> Inspection --> Packing and

shipment.

2 More than ten years electric design experiences.

Our company can design software and hardware independently. We are

proficient in digital, analog circuits, and proficient the software

for design, such as PROTEL, POWER PCB, etc. We are familiar with

MCU, such as ATMEL, MICROCHIP, ST, TI and SAMSUNG, etc. We have the

perfect laboratory equipment. We have unique theory and experience

for EMC and EMI.

Ten years we designed products cover a wide field of intelligent

home appliances, automotive electronics, industrial control

equipment, intelligent instruments, etc. We often provide unique

and constructive suggestion to customer according to new products’

design demand. So that let the new products get better cost –

effective and more competitive.

3 Improved manufacture equipment.

We have several own automation production lines, with SMT machine,

reflow welding machine, wave welding machine, and other automatic

production equipment. Fully meet customer requirements for

production efficiency and capacity.

4 Improved management system.

We set up from the feed (IQC), process (IPQC), final inspection

(FQC), to the shipment (OQC), and the management system of

improvement of quality, fully meet the requirements of customer to

our products quality.

Lead Time For Production Orders:

| Sample | Lead time(days) | Mass production | Lead time(days) |

| single sided | 1~3 | single sided | 4~7 |

| double sided | 2~5 | double sided | 7~10 |

| multilayer PCB | 7~8 | multilayer PCB | 10~15 |

| PCB assembly | 8~15 | PCB assembly | 15~30 |