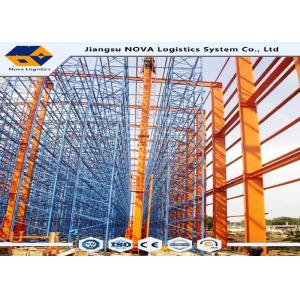

Warehouse Automated Retrieval System Pallet Racking

Add to Cart

Automatic Storage and Retrieval System

Factory Sale ASRS managerment Automatic Storage system

We can provide flexibility in storing various types of material of varying size and weight based on warehouse complete length and clear height.It is a safe, fast and very convenience system with 100% accessibility.

ASRS Stacker Crane Specification

Brief Instruction:

Safe, adjustable, pretty in appearance

convenient for knocked-down, easy to assemble and disassemble.

The deck can be adjusted vertically in the pitch of 75mm.

Each layer can bear about 1000kg-4000kg and excellence in performance

Safe and durable: Certificated by the ISO9001 quality control system.

Pallet racking is made of cold rolled special shaped steel, with safe and excellent loading capacity. It is very popular in the industries, factories and large shopping

Size & Load | customized load and size,total height can reach 40 meters | ||

Horizontal running speed | 0-240m/min by frequency control | ||

Lifting speed | 0-60m/min by frequence control | ||

Positioning method | Laser ranging + rotary encoder,photoelectric address | ||

Positioning accuracy | -/+3;-/+5 | ||

Specifications

1. CAD drawing can be provided.

2.color can also be designed

3.surface treatment is electrostatic power coating.

Structural feature:

1.Racking

1).AS/RS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure.

2).Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer.

3). AS/RS System is mainly used in the food, tobacco, electronic, mechanical and armament industry.

Model: NH heavy duty pallet racking

2. Stacker

Structural feature:

1).Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; all the way tracing technology by information transferring;

2). electric components are imported from abroad; touching screen interface for easy operation; making manual, semiautomatic, automatic and linkage control come true; used in many situations by combining with other logistics equipment.

| Model | Loading Capacity (kg) | Height | Walking Speed | Remark |

| DPL-0.1T | 100 | 5-30m | 160m/min | Customized based on client’s requirements |

| DPL-0.5T | 500 | 160m/min | ||

| DPL-1T | 1000 | 160m/min | ||

| DPL-2T | 2000 | 120m/min | ||

| DPL-3T | 3000 | 100m/min |

3 .Conveying system

Structural feature:

Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments.

Specification:

4. Controlling system

Structural feature:

Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by SIEMENS S7-300 controller can operate all conveyors offline, doing conveying of goods automatically.

Please refer to the attached drawing for details of conveying system

5. WMS System

Hardwares of WMS System: star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods.

Softwares of WMS System:

Operating system: WINDOW 2000X SEVER

Data-base: MS SQL SEVER 2000X

Warehouse management software: WMS

Equipment controlling software: ECS

Bar code management software: RFS

6. Other related equipment

Other related equipment include switching cart, rail cart, O/R table, automatic guided vehicle, auto-picking system, electronic label, pallet lift and so on.

| Others: | ||

| Design: | professional design for your requirment:include choose the correct type for you,CAD drawing | |

| Price | direct Manufacture price,according to your quantity,payment | |

| Package | standard export package | |

| Payment | 30%prepaid T/T,L/C at sight FOB,CNF,CIF | |

| Shippment | FOB NANJING,FOB SHANGHAI | |

| CNF/CIF destination port | ||

| Quick Delivery. | Within 40 days for ordinary order quantity. Big production capacity allow us in a position to make quick delivery. | |

| Certification | CE:if you need,can make for you others:ISO9001,ISO14001,ISO10012 | |

| Important information for quick quotation: | ||

| 1. Racking's DxWxH | ||

| 2. Loading capacity per level | ||

| 3. Quantity of levels | ||

| 4.The size of warehouse | ||

Route:

Our office and factory are located in Nanjing, Jiangsu Province, China

1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in Nanjing South Railway Station.

Welcome to you.

We are professional manufacturer of all types of Racking system since 1997, supply you with quality products at competitive prices. We would like to be your reliable supplier and trusted friends.