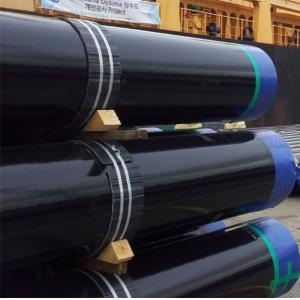

Pipeline High Temperature Corrosion Resistant Coatings Heavy Corrosion Prevention

Add to Cart

Pipeline High Temperature Corrosion Resistant Coatings Heavy Corrosion Prevention

1, The product is non-toxic, does not contain solvents and does not

contain volatile toxic substances, so there is no toxic, no fire,

no "three wastes" emissions and otherpollution problems, in full

compliance with the requirements of the state environmental

protection law.

2, Raw material utilization rate is high, the powder can be

recycled, the utilization rate is over 99%.

3, Before being treated, a one-time construction, no base coating,

you can get enough thickness of the coating, easy to achieve

automated operation, high production efficiency, therefore it

reduces the cost.

4, Coating density, adhesion, impact strength and toughness are

good, the edge angle coverage rate is high, it has excellent

chemical resistance to chemical corrosion and electrical insulation

properties.

5, Powder coating is convenient for storage, transportation safety.

| Description | Powder coating | |

| Another Name | Powder paint,Electrostatic powder coating, thermosetting powder coating | |

| Type | Epoxy resin series | |

| Main Material | Epoxy resin and hardner | |

| Advantage | Good adhesion,good mechanical property,strong coating film, | |

| excellent insulation,anticorrosion,energy-efficient,convenient operation. | ||

| Application Field | Apply to anticorrosive and insulative products: | |

| Anticorrosion pipeline,rebar,bridge,steel structure, | ||

| pylon,tank,marine fittings,electric control cabinet, | ||

| switch components,lighting sets. | ||

| Application Condition | Electrostatic spray/Triboelectric gun spray. | |

| Recommended curing condition:200 degree centigrade for 12 minutes | ||

| (object surface temperature),range from 190 degree centigrade | ||

| for 20 minutes to 210 degree centigrade for 8minutes. | ||

| Recommended film thickness:50~80um, range from 40~150um | ||

| Physical Property | Specific gravity | 1.4~1.8g/cm3 as per formula and color |

| Particle size | average 35~40um | |

| Test Condition | Substrate | 0.5mm thickness cold rolled steel sheet |

| Pretreatment | Remove rust and grease | |

| Film thickness | 50~80um | |

| Curing temperature | 200 degree centigrade for 12 minutes | |

| Mechanical Property | Pencil hardness | ISO 15184:1998,2H |

| Adhesion (by griding) | GB/T 9286-1998,0grade | |

| Impact test | GB/T 1732-1993,≥50 kg.cm | |

| Bending test | GB/T 6742 ,≤2mm | |

| Cupping test | GB/T 9753,≥7mm | |

| Chemical and Durability Test | Salt spray test | GB/T 1771,≥1000 hours,no obvious change , |

| crossion width at cross≤2mm | ||

| Heat and moisture test | GB/T 1740,≥1000 hours,no change | |

| Package | Inside by two-ply PVC bag,outside by carton,net weight 20kg | |

| Storage Condition | Store in dry ventilated room,temperature under 35 degree centigrade, | |

| avoid direct sunlight. | ||

| Shelf Life | Six months | |

| Health and Safty | Raw material of powder coating don't contain toxic substance, | |

| no toxic gas produced during curing.Please wear dust mask in operation | ||

| to avoid inhelation of powder.Please avoide prolonged skin contact | ||

| with powder,wash out powder with soap and water. | ||