High Speed Step Tile Roll Forming Machine / Tiles Making Machine With 19 Rollers

Add to Cart

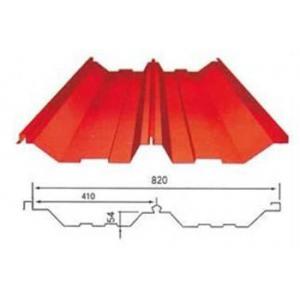

Roof Sheet Roll Forming Machine,JCH-820 Folding Tamping Plant,Coloured Steel Tile Forming Machine

Parameters

| 1.Suitable material | Color steel sheet , galvanized steel sheet,aluminum sheet |

| 2.Installation Dimension (L*W*H): | 6.5m*1.5m*1.4m |

| 3.Main motor power | 3KW with Cycloidal reducer |

| 4.Hydraulic station power | 3KW |

| 5. Hydraulic oil pump | CB-E 310 |

| 6.Thickness of material | 0.2mm~0.8mm |

| 7.Diameter of principal axis | Φ70-90mm |

| 8.Material expand width | 1000,1200,1250mm |

| 9.Electric tension | 380V 3phase 50HZ or as the customer's requirements |

| 10.Material of roller | High grade 45# forged steel plated with hard chrome plating |

| 11.Controlling system | PLC |

| 12.Processing speed | 3-6m/min |

| 13.Processing precision within | 1.00mm (depend on design) |

| 14.Material of cutting blade | Cr12 mould steel with quenched treatment |

| 15.Kind of drive | 0.6 inch chain link bearing model 6210 |

| 16.Roller station | 19 Rollers |

| 17.Roller material | high grade 45#steel; Cr12 quenching |

| 18. Leak frame load-bearing | 4.6T |

PS: the above are for reference; customized design is provided.

Working Flow

Process

* The process of roll forming is one of the simpler manufacturing processes.

1. It typically begins with a large coil of sheet metal, between 1 in. and 20in. in width, and 0.004 in. and 0.125 in. thick, supported on an uncoiler.

2. The strip is fed through an entry guide to properly align the material as it passes through the rolls of the mill, each set of rolls forming a bend until the material reaches its desired shape.

3. Roll sets are typically mounted one over the other on a pair of horizontal parallel shafts supported by a stand(s).

4. Side rolls and cluster rolls may also be used to provide greater precision and flexibility and to limit stresses on the material.

5. The shaped strips can be cut to length ahead of a roll forming mill, between mills, or at the end of the roll forming line.

1. We provide our customers with 1 year warranty.

2. Any parts damaged because of quality problem will be changed for free within the first year.

3. Technical support is provided for free at the whole life of the machine.

4. Over-sea service is provided; the cost thus incurred shall be paid by the buyer.

1. Standard packaging: Main machine is naked. Computer control

system is packed by carton box. Hydraulic pump in waterproof bubble

wrap. spare parts in carton box.

2. pack according to customers' requirements.

1. What's your payment terms?

Payment: 30% deposit by T/T before production and the balance 70% after inspection confirmation before shipment.

2.The delivery time?

We deliver the machine within 30-45 days after receiving the deposit.

3. What services do you provide?

We provide our customers with 1 year warranty and technical support is provided for free during whole life of our equipment.

Machine shows