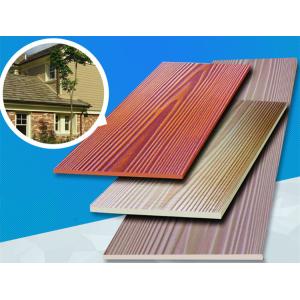

Water Resistant 12mm Fibre Cement Board Cladding Internal Environmental Friendly

Add to Cart

NEW 12mm Wooden Grain Fiber Cement Board Siding Wholesales

Technical Information for wooden grain fiber cement board:

Density(g/cm3): 1.4-1.7

Water absorption(%):≤28

Wet expansion(%):≤0.25

Ignitability: Incombustibility A class

Water penetration: Allow wet trace on back without any drops of water

Flexural Strength (Mpa): Dry: ≥16.4 Saturated: ≥13.4

Frost resistance: 25 cycles under freezing and thawing, no cracks, no layers

Radioactivity: Environmental protective A class

Asbestos: 100% free of asbestos

Thermal conductivity: 0.30(26ºC) W/ (m.K)

Drying Shrinkage: <0.1%

Free Moisture at Equilibrium Moisture Condition: <10%

The main advantages of our wooden grain fiber cement board:

1. Beautiful appearance of our wood grain fiber cement board

2. Good durability of our wood grain fiber cement board

3. Excellent fire-proof and damp-proof performance of our wood grain fiber cement board

4. Anti-cold and high temperature resistance of our wood grain fiber cement board

5. Low expansion rate, low contractibility, no shape changing.

6. Being easy to be processed and fixed

7. Environmental protection type of our wood grain fiber cement board

8. Surface can be coated and brushed

The application of the wooden grain fiber cement board:

1. Old and new building curtain walls, exterior walls and other outdoor systems

2. European and American styles of architecture and high-end villa roof

3. Outdoor hall, office, building facade and podium

4. Kitchen, bathroom, bathrooms, changing rooms and other damp places

5. Subway stations, tunnels and underground works

6. Exterior wall decoration system

7. High quality requirements of the ceiling

8. Environmental requirements, particularly Germany occasions

9. Any external wall of villa can use our wood grain wall panel

Safety capability:

| Item | Index | Instruction |

| Asbestos contain | 100% asbestos free | Safe for application |

| Radioactivity | <1.0IRa | Safe for application |

| <1.0Ir | Safe for application | |

| Incombustibility | A1 | The highest grade |

INSTALLATION STEPS:

1. Check to be install wall is smooth and clear wall obstructions.

2. Find out the pending installation of the wall benchmark standards, and pending installation the wall Simiandan line mark to prepare the keel.

3. Emissions and a fixed keel, the keel can be used 50 # light steel keel 2.5 * 3cm wooden poles can also be used. Will keel vertical direction by 60 cm spacing in the wall, expansion fasteners for nails or screws. Requirements for anti corrosion material, or embalming fluid, asphalt preservative treatment of timber with a wooden keel; doors and windows have to be laid around strengthening the keel.

4. Start the installation from the bottom of the first layer of peg board (bottom), and nail or 3.5cm long self-tapping screws to hang the board keel; Note: If you use self-tapping screws in advance with twist drill pre-drilling and nail The plane 0.5-1mm head sink into the external walls of three Lok grain peg board, nail head position to be treated with preservatives and wall putty Phi flat; board nail holes from the board along not less than 1.2cm in a uniform 1.5cm is better ; from the two boards side 2cm.

5. Installation of a second three Lok siding lap method using the same fixed (up and down the two hanging panels overlap to cover 2.5 cm) and so on to install other peg board. Note that when the width of the wall over the length of the peg board, two of the same horizontal line hanging board interfaces should be in the keel, and shall not be vacant connection.

6. Fiber Cement Siding Board level interface to retain 35 mm joints, according to the requirements of fixed finished, can be coated with polyurethane glue (PU25) or tile adhesive to fill joints; one end of the peg board and angles or exterior angle connected to the Department should move closer to the natural, and leave the appropriate gap with glue or tile adhesive seal; installed on top of the last piece of peg board, peg board and the top of the cornice junction should also adhesive seal to the plastic or tiles to achieve a waterproof purpose.

7. Install Fiber Cement Siding Board to the door, window position,

cutting the corresponding shape with the Door, window cover shape

loft hanging board should be installed to avoid through the seam

and connected at playing silicone or with tiles binder filled, to

avoid through the slit, resulting in leakage.

8. The junction of two adjacent walls (i.e. the Yin angle and Yang

angle) Fiber Cement Siding Board in need of shut up,common approach

45 degrees chamfer patchwork and dedicated Corner shut two kinds

approach. Yin angle simply two with the level of the adjacent wall

hanging board 90 degrees perpendicular to each other fixed,

caulking seams sealed can.

9. Fiber Cement Siding Board installed after a clean brush or towel and wipe again brushing the board of ash or oil. Acrylic exterior paint, the paint is better, one end of both sides brushing the surface of the peg board.

Non-fixed keel installation method:

1. Check to be to install wall is smooth and clear wall

obstructions.

2. Find out until the installation of wall benchmark standards for

the width calculation based on the peg board and pending

installation the wall Simiandan line (peg board horizontal

separation line).

3. Began installing the first piece of floor pan of water from the

foot of a wall, using the Fischer transmission Anchorage, every 50

cm peg board drilled with a drill and depth of holes drilled in the

wall, and filled into the

nylon anchor bolt and fixed the screw. Board nail holes from the

board along shall not be less than 1.2 cm, 1.5 cm in a uniform is

better; from the two boards side 2 cm.

4. The same fixed overlap method to install the second block of the

external walls of three Lok grain sandwich boards (up and down the

two hanging panels overlap to cover 2.5 cm) and so on to install

the other peg board.