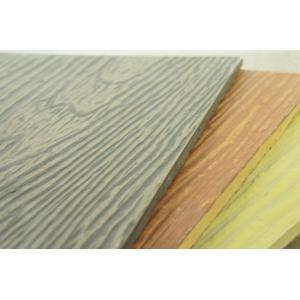

Professional Fire Resistant Fiber Cement Board And Batten Siding Customized Color

Add to Cart

Professional Weatherside Board Batten Fiber Cement Siding

Product Description

Sinoma wooden grain siding panel adopts the high quality quartz sand,silicate,natural fiber, and a variety of selected mineral. With high temperature and high pressure. The product do not have any radioactivity and harmful elements. Belongs to new, green and environmental material.The surface with the typical natural cedar wood grain,appearance is natural and beautiful. Also can prevent the attack of white ant and sawteeth animals.The wooden grain siding panel has the feature of durability,flexibility and creativity, more stable and durable than wood products.Because of the lower cost and excellent properties, it is accepted by the foreign and domestic customers, also the best choice of all kinds of construction. When choose the coating material, we recommend environmental water-based paint.For example:water-based pure acrylic coating and so on.

1. High density, 100% asbestos free, fibre silicate board

2. Suitable for internal wall and external wall

3. Grade A non-combustible

4. Dimensionally stable

5. Stable dimensions

6. Easy to install

7. Damp proof

8. Insect proof

Sizes:

| Thickness | Width | Length |

| 6-12mm | 150, 200, 1200 mm | 2400, 3000 mm |

Specification:

| Water content | ≤10% |

| Water absorption(plain) | ≤30% |

| Swelling rate | ≤0.25% |

| Thermal shrinkage | ≤0.5% |

| Anti-bending strength | ≤12MPa |

| Water tightness | The reverse side allows showing water mark but not dropping after 24hours |

| Freezing resistance | it doesn't show break and layer after 25 timers freeze thawing |

| Impact resistance | without continuous crack after one shock |

| Incombustibility | Class - A1 |

| Packing | Wooden Pallet and other packing way offered |

| Loading | 20 feet container ,40feet container ,40HQ container |

| Sample Policy | Sample offered in 10 days |

| Service | Phone, Trademanager, E-mail and Fax are available, welcome to visit us |

Installation

Fiber cement cladding is a very heavy product and requires two people to carry the uncut sheets. Thin fiber cement cladding is fragile before installation and must be handled carefully; it is prone to chipping and breakage if improperly handled.

Once the product is cut it may again require two people to install – one to hold the sheet flush against studwork and the other to nail the product in place.

Cutting fiber cement cladding sheeting usually requires a mechanised saw or metal hand shears and sheets can be cut to size in three ways:

- Thinner sheets can be scored with a heavy duty cutting blade and snapped

- Purpose made "fibro cutter" (an Australian term)

- Thicker and denser sheets require cutting by a mechanical saw using a diamond blade (Masonry blade)

- 1/8 spacing required between end-joints (cladding seams) later to be filled with caulking made for fiber cement siding

- Metal 6"x6" step flashing required behind overlapping seams to prevent sheathing damage from water

- Hot dipped Galvanized roofing nails to hang fiber cement siding

Some caution must be exercised to properly ventilate areas where fiber cement siding (FCS) is being cut; long-term exposure to the silica dust generated during the installation process can cause silicosis.

Fiber cement cladding can be painted before or after installation. (For areas of exposure, weatherproof paint must be used.) Once the product is fixed the joints are usually covered with timber battens and the entire wall surface is painted.

Durability

The external cladding products require very little maintenance once installed and painted. The thicker/denser fiber cement products have excellent impact resistance but the thinner less dense products need to be protected from impact. Compared to wooden siding, fiber cement is not susceptible to termites or rot.[2]

Fiber cement siding using base board materials that have been classified, by accredited laboratories, as Category A according to BS EN 12467: 2004 Fiber-cement flat sheets - Product specification and test methods are sidings which are intended for applications where they may be subject to heat, high moisture and severe frost.

Fire resistance

Fiber cement cladding is a non combustible material which is widely used in high bush fire prone areas throughout Australia .

While the best possible Reaction to Fire Classifications are A1 (construction applications) and A1Fl (flooring applications) respectively, both of which mean "non-combustible" according to European standard EN 13501-1: 2007, as classified by a notified laboratory in Europe, some fiber cement boards only come with Fire Classification of A2 (limited combustibility) or even lower classifications, if they are tested at all.