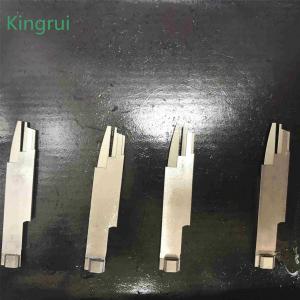

Electric Discharge Machining HPM31 Precision Mould Parts

Add to Cart

Custom Precision Mould Parts for Plastic Injection Mould

Main Features of The Product

Kingrui with development history of more than 11 years in the field , mainly provides customized processing services for non-standard precision plastic mold parts. In addition to precision auto mold parts, EDM spare parts, precision grinding parts, wire EDM parts and industrial cutting tools( food processing knife, packing knife, paper cutter, etc. ) can be provided.

A. Category of product: Precision auto parts

B. Material: HPM31, the material can be chosen according to the customer's requirements

C. Process/ Technology: The main processing techniques are Sadegh discharge and plane grinding

D. Size: Custom as your drawings

E. Shaping mold: Plastic injection mold

F. Certification: KINGRUI ISO 9001 : 2008 certification

G. Quality control: All of our engineers and sales concern and active in every engineering and manufacturing stages by ISO standard, to make sure that only quality parts leave our plant.

What Can We Do?

| Main Technology | Japan Sodick super- mirror and electro- discharge processing, surface grinding processing, punch forming, and so on. |

| Material | Steel, stainless steel, zinc, brass, copper, iron, aluminum and so on |

| Surface Treatment | PVD coating, mirror polishing, DLC coating and more |

| Main products | Plastic injection mold parts |

| Main shipping | International reliable express: DHL, or according to your requirestments |

As shown above, they can be changed according to the customer's requirements. As long as you are satisfied, we are willing to pay 100% efforts.

Machining Capability

Surface- grinding machines | 15 sets |

Internal- external lapping machines | 4 sets |

Japan mitsubishi mirror EDM | 4 sets |

Milling | 2 sets |

Japan Sodick discharging Machines | 4 sets |

Centerless grinder Machines | 2 sets |

Wire-EDM Machines | 2sets |

High- speed cnc engraving and milling machines | 4 sets |

Inspection

In order to ensure the quality of the orders, our independent

quality inspection members to carry out strict inspection at each

stage:

(1). Incoming material inspection

(2). Inspection of work-in-progress

(3). Finished product inspection

All of our operations are strictly compliant with ISO 9001: 2008

guidelines

We own 2.5Dprojector, various height Gages, two dimension and other

testing equipments.

Packaging & Delivery

Packaging Details

--- According customer request to custom

--- Our common packaging: PE film, plastic box, plastic bag and carton.

Delivery Time

Confirm with customer, Usually, it takes 5- 15 working days

Shipment Details

By international express, such as: DHL, TNT, EMS, FEDEX, and so on, or as request.