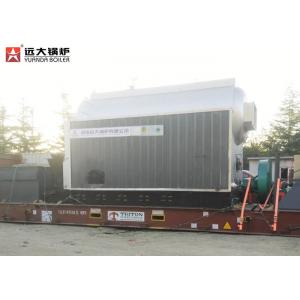

Safe And Reliable Bagasse Fired Steam Boiler / Coal Fired Steam Boiler For Paper Mill

Add to Cart

6Ton Bagasse Fired Steam Boiler Chain Grate Boiler For Paper Mill

Boiler structure features

1. DZL chain grate boiler is a kind of horizontal three-return fire

and water tube composite boiler.

2. In the boiler drum there is a thread smoke tube and left and

right side of the furnace have light pipe cold water thickness.

3. It adopts light chain grate, which can realize the mechanical

stoking together with air blower and induced draft fan for

mechanical ventilation.

4. Besides, it has slag extractor for realizing the automatic

de-slagging, and its furnace adopts new-type energy-saving arch.

5. The fuel is put on the grate from the coal bucket, and then goes

into the furnace for firing.

Working Process: The fire is refracted through the back arch and

transferred into the front smoke box through the two sides of host

combustion chamber,then refracted into the thread smoke tube of

boiler drum from the front smoke box, through the back smoke box

going into the economizer,and then injected into the atmosphere

from the induced draft fan drafting through the chimney flue to the

chimney.

Boiler running advantages

1. High quality of steam

2. Strong water quality adaptability

3. The output power remain constant

4. Low running cost, safe and reliable

5. Short installation time, low installation cost

6. Small size appearance, low investment in boiler room

7. The boiler is heating up quickly and have high heat efficiency

8. Low original dust concentration,environmental protection and energy conservation

Technique Parameter Table

| Boiler Model | Rated capacity | Rated pressure | Steam temp | Exhaust gas temp. | Design efficiency | Fuel consump | Delivery Mode |

| t/h | MPa | ℃ | ℃ | % | Kg/h | ||

| DZL1-1.0-AII | 1 | 1 | 184 | 157 | 80 | 118 | Package |

| DZL2-1.25-AII | 2 | 1.25 | 194 | 163 | 80 | 238 | Package |

| DZL4-1.25-AII | 4 | 1.25 | 194 | 180 | 80 | 472 | Package |

| DZL6-1.25-AII | 6 | 1.25 | 194 | 166 | 80 | 685 | Package |

| DZL10-1.25-AII | 10 | 1.25 | 194 | 151 | 80 | 1128 | Assembled |

| DZL15-1.25-AII | 15 | 1.25 | 194 | 161 | 81 | 1698 | Assembled |

| DZL20-1.25-AII | 20 | 1.25 | 194 | 150 | 81 | 2241 | Assembled and Semi-Assembled |

| DZL30-1.25-AII | 30 | 1.25 | 194 | 157.6 | 81 | 3380 | Semi-Assembled |

| DZL40-1.25-AII | 40 | 1.25 | 194 | 162.2 | 81 | 4481 | Semi-Assembled |

This is just part of the product parameters, if you want to know more detailed parameters of the boiler, please feel free to contact us.

Boiler application

1. Food industry: steam can be used for food disinfection, cooking;

Wine industry need to use steam;

2. Petrochemical industry: steam can be used to heat oil, to

strengthen the liquidity of oil;

3. Foam, furniture production: the steam can be used for producing

foam. When making furniture, wood needs to be dried with steam;

4. Filling block production:steam used for drying the aerated

brick;

5. Washing ironing industry: generally used in laundry, including

dry cleaning machines, dryers, washing machines, dehydration

machines, ironing machines, iron and other equipment supporting the

use;

6. Packaging machinery industry: labeling machines, sets of

standard machine;

7. Bio-chemical industry: fermentation tank, reactor, sandwich pan,

mixer, emulsifier and other equipment;

8. Food machinery industry: tofu machine, steamer, sterilization

tank, packaging machines, paint equipment, sealing machines and

other equipment;

Our service

Warranty: One-year warranty and full-life service for all of our

steam boilers

Boiler spare parts service: A full range of original spare parts

are available for all Yuanda boilers

Service before sale: Provide relative technical data for customer

choosing equipments,layout drawing,foundation,general drawing.

Service after sale: Help customer for installation and traing.

Regarding to the installation and training, the buyer should take

all the correlative charges (accommodation and food , round -trip

tickets).

Maintenance and repair for one year.

Yuanda should provide boiler technical service and operation

guidance for whole life long.