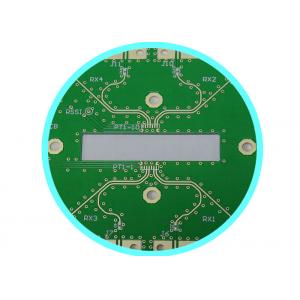

System Printed Board High Frequency Rogers PCB Board Audio Amplifier Application

Add to Cart

System Printed Board High Frequency Rogers PCB Board Audio Amplifier Application In 0.79mm

Quick detail:

| Origin:China | Special: High frequency pcb |

| Layer:4 | Thickness:0.79mm |

| Surface: ENIG | Hole:0.2 |

Features:

1. Rogers pcb multilayer pcb with high frequency can improvide the

products quality ,with high techolonogy treatment improve the life

cycle of the products .Immersion gold surface finish make the pcb

's conductive performance enhancements. Multilayer pcb design ,the

precision of the pcb improves much more better . Low dielectric : 3

dielectric conductivity much more precision .

System Printed Board High Frequency Rogers PCB Board

Quick detail:

Material: Rogers 4350B 0.254MM 0.508MM

PP material Rogers 4450

Core: 3 or 4

Stack up files: Necessary

Gerber files:Necessary

System Printed Board High Frequency Rogers PCB Board The basic characteristics of a high frequency board material

requirements are the following:

(1) dielectric constant (Dk) must be small and very stable, usually

the smaller the better signal transfer rate and the dielectric

constant of the material

Inversely proportional to the square root of high dielectric

constant is likely to cause the signal propagation delay.

(2) the dielectric loss (Df) must be small, mainly affect the

quality, the smaller the dielectric loss signal transmission of the

signal loss is smaller.

(3) as far as possible consistent with the coefficient of thermal

expansion of the copper foil, copper foil separated because of

inconsistency will cause changes in the hot and cold.

(4) to low water absorption, high water absorption will affect the

dielectric constant and dielectric loss when damp.

(5) Other heat resistance, chemical resistance, impact strength,

peel strength, etc. must also be good.

Typical Applications:

- Space Saving Circuitry

- Patch Antennas

- Satellite Communications Systems

- Power Amplifiers

- Aircraft Collision Avoidance Systems

- Ground Radar Warning Systems

- Datalink on cable systems

- Remote meter readers

- Power backplanes

- LMDS and wireless broadband

- Base station infrastructure

System Printed Board High Frequency Rogers PCB Board Rogers high frequency pcb widely used in the area of high technologies like communication device,Electronics,Aerospace,Military industry and so on. we have accumulated abandunt experiences in the line of high frequency microwave business for which widely apply to power divider,combiner,power amplifier,line amplifier,base station,RF antena,4G antena etc.

We have sufficient rogers material raw as follow:RO4003C,RO4350B,RO4360,RO4533,RO4535,RO4730,RO4232,RO4233,RO3003,RO3006,RO3010,RO3035,RO3203,RO3206,RO3210,RO3730,RO5780,RO5880,RO6002,RO3202,RO6006,Frequently-used is 4003C,4350B,5880

So we can do pcb circuit board with your detail requirements in the case of you send us gerber files or any other files

Parameter:

| o | Item | Data |

| 1 | Layer: | 1 to 24 layers |

| 2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| 3 | Board thickness: | 0.20mm to 3.4mm |

| 4 | Copper thickness: | 0.5 OZ to 4 OZ |

| 5 | Copper thickness in hole: | >25.0 um (>1mil) |

| 6 | Max. Board Size: | (580mm×1200mm) |

| 7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

| 8 | Min. Line Width: | 3mil (0.075mm) |

| 9 | Min. Line Spacing: | 3mil (0.075mm) |

| 10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| 11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| 12 | Shape tolerance: | ±0.13 |

| 13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| 14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| 15 | Certificate: | UL,SGS,ISO 9001:2008 |

| 16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

| 17 | Profiling: | Punching, Routing, V-CUT, Beveling |

Features

• High Thermal Performance

Tg: 180°C (DSC)

Td: 340°C (TGA @ 5% wt loss)

Low CTE for reliability

• T260: 60 minutes

• T288: 30 minutes

• RoHS Compliant

• UV Blocking and AOI Fluorescence

High throughput and accuracy during PCB

fabrication and assembly

• Superior Processing

Closest to conventional FR-4 processing

• Core Material Standard Availability

Thickness: 0.002″ (0.05 mm) to 0.125″

(3.2 mm)

Available in full size sheet or panel form

• Prepreg Standard Availability

Roll or panel form

Tooling of prepreg panels available

• Copper Foil Type Availability

Standard HTE Grade 3

RTF (Reverse Treat Foil)

• Copper Weights

½, 1 and 2 oz (18, 35 and 70 μm) available

Heavier copper available upon request

Thinner copper foil available upon request

• Glass Fabric Availability

Standard E-glass

Square weave glass fabric available

Spread glass fabric available

• Industry Approvals

IPC-4101C /21 /24 /26 /97 /98 /99 /101 /126

UL - File Number E41625 as PCL-FR-370HR

Qualified to UL's MCIL Program

PrePreg Material

| Parameter | Value |

| Specific gravity/density | 1.850 g/cm3 (3,118 lb/cu yd) |

| Water absorption | −0.125 in < 0.10% |

| Temperature index | 140 °C (284 °F) |

| Thermal conductivity, through-plane | 0.29 W/(m·K), 0.343 W/(m·K) |

| Thermal conductivity, in-plane | 0.81 W/(m·K), 1.059 W/(m·K) |

| Rockwell hardness | 110 M scale |

| Bond strength | > 1,000 kg (2,200 lb) |

| Flexural strength (A; 0.125 in) - LW | > 440 MPa (64,000 psi) |

| Flexural strength (A; 0.125 in) - CW | > 345 MPa (50,000 psi) |

| Tensile strength (0.125 in) LW | > 310 MPa (45,000 psi) |

| Izod impact strength - LW | > 54 J/m (10 ft·lb/in) |

| Izod impact strength - CW | > 44 J/m (8 ft·lb/in) |

| Compressive strength - flatwise | > 415 MPa (60,200 psi) |

| Dielectric breakdown (A) | > 50 kV |

| Dielectric breakdown (D48/50) | > 50 kV |

| Dielectric strength | 20 MV/m |

| Relative permittivity (A) | 4.8 |

| Relative permittivity (D24/23) | 4.8 |

| Dissipation factor (A) | 0.017 |

| Dissipation factor (D24/23) | 0.018 |

| Dielectric constant permittivity | 4.70 max., 4.35 @ 500 MHz, 4.34 @ 1 GHz |

| Glass transition temperature | Can vary, but is over 120 °C |

| Young's modulus - LW | 3.5×106 psi (24 GPa) |

| Young's modulus - CW | 3.0×106 psi (21 GPa) |

| Coefficient of thermal expansion - x-axis | 1.4×10−5 K−1 |

| Coefficient of thermal expansion - y-axis | 1.2×10−5 K−1 |

| Coefficient of thermal expansion - z-axis | 7.0×10−5 K−1 |

| Poisson's ratio - LW | 0.136 |

| Poisson's ratio - CW | 0.118 |

| LW sound speed | 3602 m/s |

| SW sound speed | 3369 m/s |

| LW Acoustic impedance | 6.64 MRayl |

Rogers material in stock:

| Brand | Model | Thickness(mm) | DK(ER) |

| F4B | F4B | 0.38 | 2.2 |

| F4B | 0.55 | 2.23 | |

| F4B | 0.225,0.3,0.5,08,1,1.2,1.5,2,2.5,3.0 | 2.65 | |

| F4Bk | 0.8,1.5 | 2.65 | |

| F4B | 0.8 | 3.5 | |

| FE=F4BM | 1 | 2.2 | |

| Rogers | RO4003 | 0.254 0.508,0.813,1.524 | 3.38 |

| RO4350 | 0.254 0.508,0.762,1.524 | 3.5 | |

| RO5880 | 0.254.0.508.0.762 | 2.2 | |

| RO3003 | 0.127,0.508,0.762,1.524 | 3 | |

| RO3010 | 0.635 | 10.2 | |

| RO3206 | 0.635MM | 10.2 | |

| R03035 | 0.508MM | 3.5 | |

| RO6010 | 0.635MM, 1,27MM | 10.2 |

Competitive Advantage:

1) With UL,ROHS,ISO,IPC

2).Lead time:3-10 working days

3)Competitive price best quality

4).Rich 20 years experience in High Tg Multilayer PCB .

What Information customer need to provide for quotation ?

1. PCB Gerber files ,protel,powerpcb,Autocad,etc.

2. BOM list for PCB assembly.

3. Send us your sample PCB or PCBA.

4. OEM is acceptable.

Company Service:

24 hours quick sample is avaliable here.

reply Customer's any enquiry within 3 hours;

Blind buried hole ,crossed blind hole can be done

24 hours Engineering Gerber files treatment.

24 hours English Engineering Questions Confirmation by E-mail.

Supply the best project fit for production customized