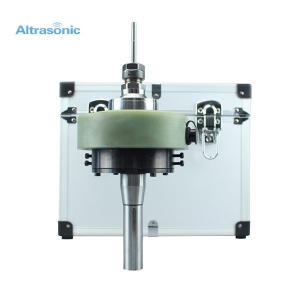

HSK63 20khz High Vibration and Spindle Ultrasonic Assisted Machining Equipment for CNC Machining Center

Add to Cart

HSK63 20khz High Vibration and Spindle Ultrasonic Assisted Machining Equipment for CNC Machining Center

Specification:

| Frequency | 20 Khz |

| Output Power | 1000 W |

| Voltage | 220 V |

| Switch | Handle or foot switch |

| Power Adjusting | Step or continuous |

| Working Time Control | 24 Hours |

| Weignt | 30 KG ( Determined by the size of the horn ) |

| Generator | Digital Generator |

Adding ultrasonic milling device in the ordinary machine tool can valid in improve working life of tools and quality of work piece surface. Add ultrasonic milling device in numerically-controlled machine tool can enhance productivity.

Milling process can be extended to drilling process, grinding process, cutting process and so on.

Principle:

Ultrasonic machining process uses a power supply that converts conventional line voltage to 20KHz

electrical energy.

This high-frequency electrical energy is provided to a piezoelectric converter that changes high frequency electrical energy into mechanical motion.

The ultrasonic motion from the converter is amplified and transmitted to the horn and cutting tool.

This causes the horn and attached cutting tool to vibrate perpendicularly to the tool face thousands of

times per second with no side to side motion.

A recirculating pump forces E/Z Pump™ abrasive, suspended in a liquid medium, between the vibrating

tool face and the workpiece. The abrasive particles strike the workpiece at 150,000 times their own weight.

These tiny abrasive particles chip off microscopic flakes and grind a counterpart of the tool face.

The advantages of ultrasonic machining over ordinary machining:

- Virtually any hard material can be machined

- Little heat is produced

- Since the motion of the tool is up-and-down vibration rather than rotation as in traditional machining, the holes cut are not limited to circular shapes but can be any shape. Custom "cookie cutter" tools can cut complicated shapes.

- good surface finish and higher structural integrity is obtained

Applications

applying in elaborate processing for various kinds of materials especially fragile rigid material. The milling process by using rotate milling cutter is suit for processing plane, groove, all kinds of form surface (such as spline, gear and thread) and special surface of mould.

Application area: machining industry, machine tool equipment manufacturing

Application occasion: manufacturing enterprise, universities and colleges, scientific research institution, mechanical equipment transformation industry

Tag: ultrasonic vibration machine,ultrasonic drilling machine