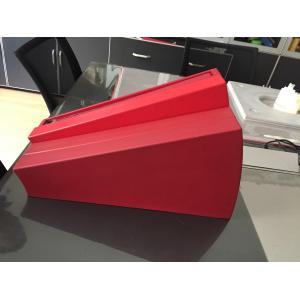

Integral High Resilience Polyurethane Foam Soft Flap Barrier Wings Gate For Gunnebo

Add to Cart

Flap barrier Wings Gate Coated by Polyurethane Integral Skin foam

Very soft surface and comfortable made for Gunnebo comapny

Flap Gate Description

This product is widely used in channel for the subway.Polyurethane soft flap is

a kind of polyurethane integral skin foam product. It can be used, whether outdoor or indoor,

without being out of shape. PU Integral skin foam product, or what we call the whole

leather molding foam plastics, can be shaped by one time casting moulding ,

forming tough skin on the product’s surface. We can make the surface pattern by

processing the mold surface. So there will be no need to use other plastic leather material

to cover the product. This kind of material is soft and elastic. There is metal frame inside,

so the flap has excellent impact resistance. Therefore, this kind of material can prevent

people from being crushed to a large degree. Polyurethane soft flap has a stable capacity

and is humanized designed, enjoying an upscale position.

Cooperated With?

Since 2010, we have cooperated with Gunnebo Security(China) Co.Ltd.

As Gunnebo requirements, we developed 6 models polyurethane foam flap to meet

different subway lines.And we can produce any color as your requirements.

And we can control seriously the flap’s hardness :ShoreA=50±5,and the flap’s density=250±50kg/m³

Welcome to ask the Specifics and parameters

Material Introduction

Integral skin, also called “self-skinning foam’’ is a microcellular core with a tough,

abrasion resistant outer surfaceIntegral skin foams come in a wide range of molded

densities,and they are the perfect solution for a broad variety of applications that require

a soft touch and feel, as well as a highly durable finish.

Fields of application

Medical technology,Handling units,Access systems,

Coating field , Mass transit application

Bank and paymentstations,

Consumer electronics,Workpiece carriers

Gallry

Why this foam?

1. Sandwich-style design with high inherent rigidity

2. Extraordinary design flexibility

3. Good thermal and acoustic insulation properties

4. Variable wall sections in a part without sink or distortion

5. Very excellent surface touching feelings

Quik Details

Values not absolute some may be altered.

Items | Test Standard | Test Result |

Burning Performance | ISO 3795:1985 | Sweep rate<100mm²/min |

Tensile Strength(foam part) | ISO 37:2005/Cor.1:2008 | 1.19N/㎡>1.17N/㎡ |

Break Elongation(foam part) | ISO 37:2005/Cor.1:2008 | 197%>150% |

Tear Resistance(foam part) | ISO 34-1:2010 Method B | 3.9N/mm |

UV | ASTM G154-06 Cycle 1 | Gray Level:4-5 |

Abrasive Resistance | ISO1294-2-1998+Cor.1:2002; Martindale Wear&Abrasion Tester; 12kPa | >1000 |

CF to Rubbing | Ref.ISO 105*12-2001 | Dry stainning degree:4; Wet dyed gray:4-5 |

Fire Resistance | ISO8191-1:1987/ISO8191-2:1988 | Conformity with flame retardancy |

Hardness(23±2°c) | ISO868/ASTM D2240 | 50 ShoreA±5 |

Density | ISO845 | 250±50kg/m³ |

Surface Fire Resistance | ASTM E162 | Conformity with flame retardancy |

The Technical data is totally provided by SGS test !

The customized Design request is available!

We are very expert in manufacturing customized Integral polyurethane

skin foam parts.

TIPS

Foams of the same density can vary considerably in strength, depending on the foam

production process.

Different production methods require different chemical formulationsand foam curing

temperatures. General Plastics’ self-skinning

integral skin foams allow items such as aircraft armrest padding to be easily removed

from the mold in the exact shape needed, and already painted or airbrushed in the desired

color.